-

Posts

972 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by GrampaJoel

-

Pampeano Belt - How to punch pattern for stitching?

GrampaJoel replied to CJJ's topic in How Do I Do That?

How about just getting a screwdriver the right width and just punch a pattern you like. It seems that thread is being used for the design, so I would think that the punched spaces wouldn’t need to be very big. As a thought to myself shared. I don’t think going over the edge of the belt would be good for the thread life. It seems to me it would be a place to wear out and then the thread design would unravel. Joel -

What will be big for the 2023 Christmas season?

GrampaJoel replied to teamroper55's topic in Leatherwork Conversation

Christmas ornaments. -

It’s very stunning. Is there a meaning to the design on the purse? Joel

-

It’s your second belt. Ok. It looks very usable. I say wear it with pride, and see what you like/don’t like about it. If you continue leather working you probably will make more. I don’t care for the black thread against the natural. I would use a light colored thread. Like off white. But that’s just me. keep going and perfect your skills. Joel

-

I don’t have an answer for you. Sorry. I have one of the numerous brands of this model pictured below. It has a heat digital reading windows. It also has a calibrated slide out table. I marked the table where my stamp hit when pressed,, and it helped get the slide out table centered. Then it became the struggle of consistency getting the stamp centered in the part that did the pressing. Very frustrating. The machine ‘ Seemed’ really cool when I first got it. It does a nice job if precision isn’t needed over and over. However,, I seldom use it now. It was just to hard to get the temperature to be the same each time. And so on and so on. instead I use a item that is like a soldering iron. I have better luck squaring things up with it. The press while very cool in idea, is like all tools. Until they are mastered, they can be frustrating. Joel

-

Bison leather pleats to leather sheet sewing

GrampaJoel replied to olivermarks's topic in How Do I Do That?

What a neat idea! I am not familiar with the machine you are using. I had a cobra class 4 for years and it would sew just about anything. So I was spoiled. I would suggest, that If your machine won’t punch through the bison, or if it is to thick to go under the presser foot. I think thinning the leather would be the next step. Bison hide is pretty tough. It should hold well, even if thinned a bit. Joel -

How much to charge for your leather goods?

GrampaJoel replied to GrampaJoel's topic in Leatherwork Conversation

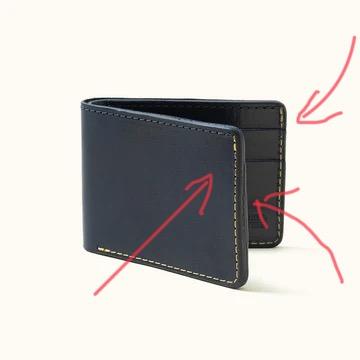

I don’t care so much about the prices. But the quality for the price is what caught my eye. here’s a photo from the site. $125.00 wallet reduced to $75.00. notice the three areas I have arrowed. Stained thread on front of the wallet. Splitting where the card slots meet the edge. Messed up sewing on inside at the card slot edges. I guess it expect more quality for $125.., or even marked down to $75.00. Joel .. -

How much to charge for your leather goods?

GrampaJoel replied to GrampaJoel's topic in Leatherwork Conversation

My original posting was to the poor quality of the wallets. I know business. 36 years of it. I know costs to operate. Managed a business of almost a $500,000.00 a week in sales. I don’t see clicker cut wallet pieces. I see poorly hand cut card slots. I see unfinished edges that don’t match. Edged, and uneven and poorly burnished , if actually burnished. I see poor sewing. Etc., etc. I see poor quality hand made wallets bragging about being made in the USA, (As if that guaranteed the high quality of their products, ) that they are selling for outrageous prices. and I don’t understand it. I just don’t get it. I doubt I ever will. Joel -

How much to charge for your leather goods?

GrampaJoel replied to GrampaJoel's topic in Leatherwork Conversation

I guess this is my beef also. I ALWAYS felt I was getting quality, if an item was marked. Made in USA. -

How much to charge for your leather goods?

GrampaJoel replied to GrampaJoel's topic in Leatherwork Conversation

Yes! $175.00 for about $20.00 worth of probably factory precut, pre colored leather. Two rivets and a $2.00 buckle. It would feel like I was robbing someone to sell at those prices. Joel -

How much to charge for your leather goods?

GrampaJoel replied to GrampaJoel's topic in Leatherwork Conversation

Yes the web site is VERY upscale. So is the picture of their store in Oregon. I truly wonder if I am seeking to produce way to much perfection in my work. I can knock out wallets like that all day. And I would toss everyone into the junk bin. But I couldn’t with a clear conscience ask people to pay for them. I would even have a hard time giving them away, knowing how poorly they would be made. Joel -

The question of ‘How much to charge?’ , has been pondered here and asked here over the years. Awhile ago a crafter asked that question here. I answered as honestly as possible in my opinion. However, my answer wasn’t well received by the ‘Original Poster’. Ok. So since then, I been questioning myself in regards to the ‘quality of goods to price ratio’ that I would charge, and what IS, real quality. I have spent months perusing many, many leather goods web sites. searching for answers to my questions. This morning I happened upon this website claiming USA hand made leather goods. https://www.tannergoods.com I looked around the site and at the items listed for sale. Their quality of build and prices. NOW, I don’t mean this as a hit or disrespect to the site or their goods for sale. I’ll explain shortly. But in my opinion, I have better quality items in my Opp’s ,,,junk pile. Hence my questioning of my thoughts about, what is real quality and it’s price ratio. Well, apparently people do buy merchandise of this quality for the posted prices from the website. I obviously don’t understand why, maybe unfinished edges,,are the new style. Perhaps pieces haphazardly cut away from their cut lines,, are in style. Perhaps edges not glued completely,,are now in style. Perhaps machine sewing using the wrong size needle to thread ration with fuzzy unfinished ends are now in style. perhaps,,,, I’m just no longer in style,,,expecting quality for dollars spent. perhaps my perceptions of quality and it’s ratio to dollars spent are no longer in style. I am getting pretty old after all. Soooo. Please take a look at the link I posted above. Enlarge the pictures of the items for sale. Tell me. Am I way out of style? I will except all replies with honest consideration. and once again. I mean no disrespect to the website or its maker(s). I am just seeking some answers. thanks Joel

-

Very very nice clean work! Joel

-

Very nice ‘precise’ work. It appears to me you are using an inverse pricking iron, as well as a regular one. That’s a nice detail I really like. well done! Joel

-

Another solo...Another Memento...

GrampaJoel replied to pzarkov's topic in Motorcycles and Biker Gear

Incredibly beautiful work. are seats like this meant to be used, or are they for show bikes? I’m curious as to how long the masterful quality of tooling holds up, if frequently used. thanks Joel -

Heritage 22 6" Brl Holster

GrampaJoel replied to Bert03241's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice. Do you cut the pattern with the laser also? -

Latest holster

GrampaJoel replied to BigBore's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Niiiiiicccceeee!!!! great job on the stitching! Joel -

Very attractive! It look nice and light. I never have cared for heavy guitar straps adding to the weight on the shoulder. I hope your friend makes a complete recovery.

-

That’s a pretty nice design. She should love it. I don’t know about lasers. how deep does it burn into the leather?

-

Sling, cuff, belt slide combo

GrampaJoel replied to BigBore's topic in Gun Holsters, Rifle Slings and Knife Sheathes

You have managed to make an ordinary set of items, extraordinary! nice going! Joel -

Sunflower Wallet

GrampaJoel replied to mikesherman's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I would suggest that you might save your wallet by pulling the pockets and re-doing them. Forgive my finger drawing. But maybe it will help. you might try using a thin leather, and instead of four pieces of leather, use just two. Folding them in half will give you the pockets. using a double sided tape on the folded pocket on the snap area/side would close the long side. Then all you would need to stitch would be the ends, and the wallet would be usable. -

The only problem I have ever had with Herman oak was when I bought tannery run. I know they say tannery run is the standard, but there is a choice, or select grading also. but even then tannery run was better quality than what I had purchased from Tandy.