-

Posts

972 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by GrampaJoel

-

Nice job! I like the design. Joel

-

Thread always untwists when saddle stitching

GrampaJoel replied to Redbeeerd's topic in Sewing Leather

You might try a braided thread. -

When machine sewing, I used to back stitch a few stitches and melt the threads on the back side. I only do hand stitching now. But I often do it the same way. I don’t use cotton thread. has always worked for me.

-

-

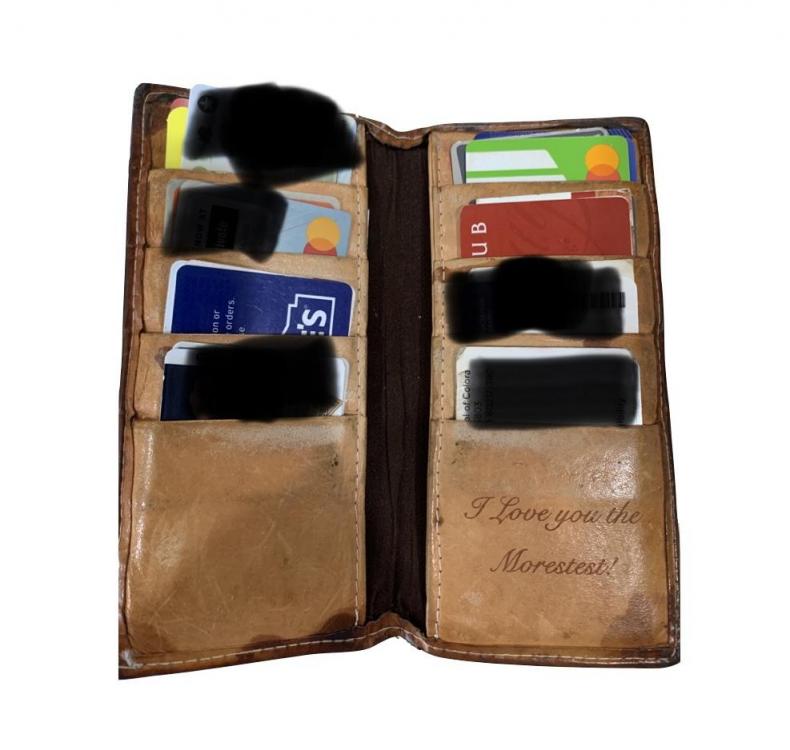

I know , this thread is a month old. But it’s cold and rainy and the shop isn’t warm yet. so I would like to add. I made this, and posted my first wallet, I made for my son, 6 years ago today. it has a silky nylon material in the pockets. The nylon material is just double sided taped in. These days I sew my pockets, but it makes me wonder. just how much longer the wallet I made for my son,,, will last. He has used it pretty hard.(a new one is in the works.) Today when new.

-

WOW! that big horned mountain goat has a lot going on. So now that you are retired, you can become a master of leather. You have lots o& time. Joel

-

Made one for myself

GrampaJoel replied to DustinSmith's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Nice belt. The tooling of Texas font is pretty cool. is the font your owe design? Joel -

Hey everyone. I’ve been watching you tube videos of wallet making on these rainy rainy days. Often times I see card stock patterns being used, that appear to have some type of sticky backing. It doesn’t appear to mark or leave a residue on the leather. And usually I have noticed it in the videos from Korea, or Japan. does anyone here know what they may be using. It looks like a good way to hold your pattern to the leather without weights or using your hand. thanks Joel

-

Very cool. Thanks for the video. I have seen that done with leather straps. I think a leather footbed was glued on also. either way,,,,It shows that much can be done without a huge cost in tools. Joel

-

Leather smell, storage smell, mildew smell?

GrampaJoel replied to Redbeeerd's topic in Leatherwork Conversation

You are welcome. Joel -

Look folks. The stand came to me from Ron’s Tools when they first started making these stands. It was in two pieces and wrapped in that stretchy clear packing plastic. It was not boxed in any way. It came to me by freight truck. I was not sure what I expected, and I wasn’t happy about it. It could have been badly damaged shipping it that way. So, I don’t feel conferrable sending it to someone wrapped the same way. and I don’t feel conferrable sending something to a person who has not even seen it in person. . Except for photos. sorry Joel

-

Looks good. but shouldn’t that ball point be a crayon?

-

My first Holster. (1942 Walther P38.)

GrampaJoel replied to Littlef's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Hey you must be a lefty. not to shabby for a lefty. Joel -

Piece for a denim jacket

GrampaJoel replied to DustinSmith's topic in Clothing, Jackets, Vests and Chaps

Cowboys n Indians. that is awesome!! incredible tooling and coloring! Joel -

It looks to me like you stitched the two pieces in different directions. when I compare the stitch holes that I can see punched. so I’m thinking you are seeing one back side and one front side. Joel

-

Wallet

GrampaJoel replied to Tim Schroeder's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

holy cow! That’s nice. I’m very impressed. And,,,that is some great stitching too! What is your spacing on those tiny tiny stitches? Wait upon blow up, it’s machine stitched isn’t it? still very nice work! Joel -

Leather smell, storage smell, mildew smell?

GrampaJoel replied to Redbeeerd's topic in Leatherwork Conversation

Years and years ago I bought 5 ‘on sale’ full hides from a (familiar if named) inexpensive country wide leather shop. I didn’t notice the acidic smell until I got home. It was almost unbelievably bad. So, I ended up hanging all five hides outside on a rope line in the sun and breeze for about 4 or 5 days. Eventually the smell faded away. After the bad smell had faded the leather was very usable. These days I always give the leather a sniff test before I buy it,,from this certain brand leather shops. Joel -

Canebrake rattler motorsycle tank bib

GrampaJoel replied to Garyak's topic in Motorcycles and Biker Gear

That’s pretty nice. I would like to see that on the bike when it’s on. Joel -

Wednesday Adams satchel template?

GrampaJoel replied to AtomicLeathers's topic in Patterns and Templates

Excellent video! those corner punches look pretty handy. nice going! Joel -

I Started A Leather Craft Youtube Channel

GrampaJoel replied to lintonleather's topic in Leatherwork Conversation

Your video was nice. It seemed well crafted. however, I think that you could go a step further and explain what you are actually doing, and why. leather workers that already have equipment like you are showing, are at or beyond your level of skills. someone as a beginner, would have no idea about what you’re doing in your edging process, with the electric edge finisher. if you want to be successful and help people learn, you need to ‘teach’ what you are doing. I wish you the best of luck. I like YouTube leather making videos Joel -

As said by everyone before me. Excellent work! you attention to detail is good too, and I like the handle snake ‘D’ rings. Joel

-

I understand the hole thing on leather belts from a personal experience. Either to tight or to loose. Really never just right. I quit wearing leather belts about 10 yrs ago. Because of the constant not fitting in the hole thing. I wear a ratchet style gun belt these days . Because it can be adjusted with a simple push of the belt in 1/4” increments. To tight? A little lever at the buckle releases the tension. My feelings are that custom made goods, of any material, seldom are truly 100% ,,what the customer has visioned in their minds. that’s why I won’t do them anymore. I make it, and if someone likes it. It’s theirs. Of course the caveat is,,, I’m not trying to earn income from my leather work anymore. best wishes Joel

-

The very last belts I made for a person were as gifts. Because I no longer charge folks, even for my time and cost. It’s a hobby. but I measured him myself twice. Then I measured his belt he was wearing. And then I made two belts for him. He insisted they have a leather piece on the buckle, just like the one he was currently wearing. It was so strange. a few weeks later after I gave him the belts, I saw him again, and I ask him why he wasn’t wearing one of the belts I had made for him. He said he was saving them for his boys when they grow up. They are 12 and 9 now.??? he didn’t say if they were to big, or to small. my take is he just didn’t like them. so ya just never know. I don’t make things for people when they ask anymore. I just got tired of people wanting something made and then not getting what they expected in their minds. Something ‘factory/production’ made. I make what I like and if someone likes it I give it to them. Joel

-

Actually the stamp in the OP was branded on with a Leatherstampmaker stamp and heating iron. it’s on the back of the wallet by the way.

-

Well I can definitely see that there are several thoughts in regards to maker marks. I may on an occasion sell something, but I sell at my cost. I don’t do repeated production work for someone else either. So I am not a business, nor have I ever really been one it true practice. I enjoy the leather work and it’s challenges, and so I guess that makes it just a hobby. My artist friend says I’m a leather artist. So I’ll except that as my title. anyway I thank each one that has responded to this thread from my heart with a big ‘THANK YOU’ for sharing your thoughts. I am attempting to modify my logo/brand/signature to the below image.