-

Posts

6,539 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Northmount

-

OP appears to be in the Willoughby, Ohio, 44094 area according to his/her IP address. Tom

-

If we ignore power factor for alternating current circuits, you can do a quick comparison of power by multiplying volts x amperes. Assuming unity power factor (which it isn't), VA would equal Watts. (And 1 horsepower = 746 Watts if you want to look at hp instead.) 240 x 1 = 240 VA 110 x 1.5 = 165 VA So obviously your 240 volt 1 amp motor is more powerful than the 110 volt 1.5 amp motor. Tom Edit: Motor you referenced is 180 W. Therefore PF = 180 / 240 = 0.75. PF of AC motors is typically 0.5 to 0.8. But again, just the VA comparison is adequate for many cases, including yours.

-

Converted the jpeg file to a PDF to make it easier to read and print out. Great tutorial. I've been thinking of trying it out. Maybe after current projects are done. Tom Leather_Mask_Making_Tutorial_by_Ranasp.pdf

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Advice for cylinder arm machine for sewing saddlebags

Northmount replied to sam000lee's topic in Leather Sewing Machines

New comes with a warranty and support. I my mind, that is too much for an old machine with a clutch motor that you are going to hate. Get one that is setup to use 138 or heavier thread. Tom -

Only the pattern is copyright. You can make as many as you want for sale or gifts. You just can't copy and sell the pattern. Tom

-

Terry's 141 MB PPT file converted to pdf, 8.8 MB. As noted above, it contains screen shoots from various web sources. Trunk Build Images.pdf Tom

-

@sold2018Need photos, shipping etc. Please read the marketplace rules and update your post. http://leatherworker.net/forum/forum/70-announcements/ Tom

-

Looks great. I like the colourful stones! Tom

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

40W Chinese Laser - Engrave and Cut Leather - Discuss

Northmount replied to Billy Hell's topic in 3D Printers and Lasers

Will not be USB powered as it uses far more power than the USB port can supply. It should have USB connectivity for programming and operation. Tom -

IP address resolves to Sydney. Tom

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Sapphire swivel knife sharpener

Northmount replied to Hasbeencowboy's topic in Patterns and Templates

photos might help Tom -

@Reddturtle moved to leather sewing machines. You should get more responses from the experts here. Tom

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

leather techniques Secrets from the Workshop

Northmount replied to Dangerous Beans's topic in How Do I Do That?

Plus 1. Really helpful to drop all background noise that does not contribute to the purpose of the video. Tom- 34 replies

-

- saddle stitch

- creasing

- (and 12 more)

-

When installing zippers, make sure the centre of each side of the zipper lines up with the centre of the edge it is being stitched to. So staple or tack or what ever method you use to hold things in place before sewing, starting at the centre and working both directions for both sides. It helps prevent skewing the zipper and making it hard to zip up as it is fighting with the heavier leather on each side. Tom

-

Try this "Flat Plate Open Three-Way". I'm no saddle expert at all, but found it at http://www.saddleonline.com/blogs/content/different-styles-western-saddle-rigging Did a Google searched for "saddle rigging ring dee plate" trying to catch the different terms I have seen. Also found this. It references 3 way plate and a source. And take a look at the bottom picture on this page. They may be able to tell you where they source them. http://www.madisonsaddlery.com/saddle.html Tom

-

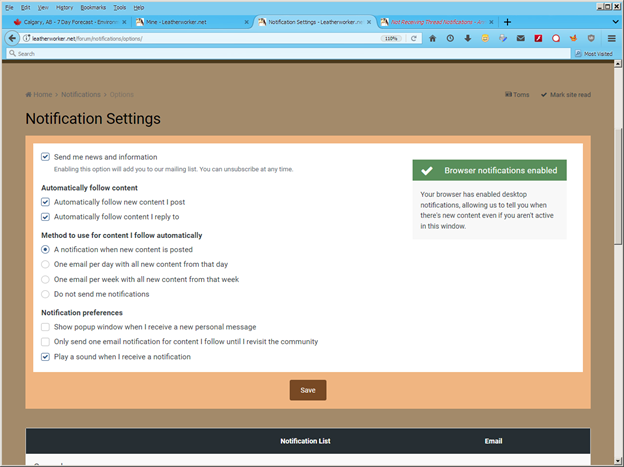

These are the settings that work for me. For some period of time, I wasn't receiving any email notifications. I don't remember which setting I changed. I suspect it was "Send me news and information" Tom

-

If you are making a 2 layer collar (lined) add a strip of poly webbing between the layers. It won't stretch and therefore the collar will retain its shape better when subjected to water and other abuses. There are some other posts about eliminating the stretch problem somewhere here if you wish to search for them. Tom

-

Unplug it, leave it sit for a while, then try again. May have to re-do the setup. This happened to someone else on the forum, but don't remember who or when. Another party had damage due to lightning strike nearby when it was left turned on. Some electronics seem to be very sensitive to power line transients. Good luck/ Tom

-

Looks like it was folded/bent tight towards the flesh side. That stretches the grain side, and when released, wrinkles the grain side. Tom

-

Looks to me like it was done with an embossing roll. Don't see any joins that you would normally see if it was stamped. Tom

-

@RB12 If you are not wanting to use foil to make coloured impressions, you can use it cold to make impressions in veg tan leather. You can also use it hot without foil to burn an impression into many types of leather. It will need to be able to operate at a higher temperature to burn impressions. You can have a die made by a photo engraving process, or by CNC milling, or other processes and use an arbour press to stamp veg tan. There are lots of routes to go. Do a search for hot foil press here on leatherworker.net and you will find several threads with more information. Tom

-

You could purchase an eBook from Tandy that describes the use of several tools. https://www.leathercraftlibrary.com/p-1141-leathercraft-tools-by-al-stohlman.aspx There a a number of other helpful books there too. Tandy and YouTube have a lot of videos describing tooling and how to do it. If you are close to a Tandy store, you could check to see when they have free tooling classes. Tom

-

Never suggested that there were any on my website. I pointed you to look/search for posts/threads done by Gottaknow. Here is the particular post I was referring to that you could have searched for. Also suggested that you look for comments he has posted to help various people. Here is a link for all content he has posted. http://leatherworker.net/forum/profile/33297-gottaknow/?do=content You should also look at content posted by Wizcrafts. http://leatherworker.net/forum/profile/11118-wizcrafts/content/ There are other sewing machine experts here besides Gottaknow and Wizcrafts. But this should be enough to get you started. You'll find the others as you peruse the site. Also many manufacturer's manuals and catalogs, some posted here, some links to other sites. The search function is just below the banner ads at the right. You can use it to search any topic you wish. Tom

-

IP address resolves to Red Bank New Jersey. @MaryMac I would recommend all users add their location to their profile. You will get better answers to your queries if they happen to be area related. Might even make connections with someone just down the road. Tom

-

@Game Moved to Sewing Machines. You'll get more response here. Search for the member @gottaknow. He has posted some training material for sewing machine mechanics. Also has posted a huge number of helps. Tom