-

Posts

5,797 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Singer 29k171 "Another journey to the unknown"

Constabulary replied to jimi's topic in Leather Sewing Machines

Jimi, thats why I asked for the parts number. I assumed the large bobbin gear box would probably fit. I once had the chance to try a 29K60 gear box (large bobbin) but it did not fit. Too bad. But I kowno there once was a large bobbin short arm patcher but that was one of the Jap "U" Singers afaik. -

Regular 29K parts you can order online from College Sewing UK as well. They sell the same parts as Sew Europe. I was in touch with Sew Europe too but their prices back then (when I restored my 29K71) were higher then from College Sewing. Just wanted to have it mentioned.

-

I´d check with RIMGM.de or Sieck.de or wdn.de f.i. They may not have them online but maybe can order them. If not possible you can try to hard solder the plate (in worst case)

- 11 replies

-

Manufacturer's Mark on Sewing Machine Hooks

Constabulary replied to Uwe's topic in Leather Sewing Machines

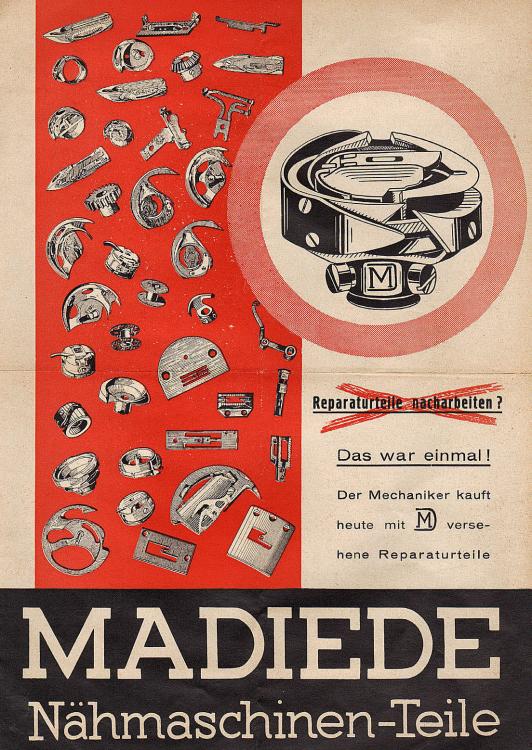

One more NTW = Nähmaschinenteilewerk (VEB NTW Dresden) A former GDR company (East Germany) which produced small sewing machine & parts. Co, still exist but is not making parts anymore. They are now specialized in hardening metal parts. Note their Company crest - its a sewing machine hook. www.haerterei-dresden.de -

wow - copying a forum almost 1:1 and then linking it in the original forum is like a slap in the face. If you don´t have friends - now you even have fewer. Anyway - good luck!

- 33 replies

-

- leather work discussion

- leather

-

(and 2 more)

Tagged with:

-

Switch from Nylon to Polyester and maybe this will solve the issue. Belief it or not - I´m sometimes even using 16/4 cotton thread that is older than me - how do I know it is older - well, its dated 1968! I´m also using a lot of polyester thread from size 40 to 11/3 (metric). Also some Cotton / Poly from different mfg´s. I have polyester thread spools where even the plastic spool broke because of its age or is faded by sunlight BUT all the thread is absolutely perfect working - no matter if I run it in a Singer 111, Singer 29K, Singer 307 zigzag or 45K. It´s not because I´m a Cheap Charley (well, maybe a little bit) but this thread just works great and why throwing it away when its still working well? I do not use nylon thread at all (have some CONSO #69 prewound but I don´t think I ever used it) Odd Chinese nylon thread from an unknown manufacturer on which an importer puts his own label on may work for work a while but in the end you never know where this thread is coming (which manufacturer) from and if you get the same thread with your next order. Different manufacturer - same label - so how can you (as a consumer) know its always the same quality from the same manufacturer? Of course all sellers / importers claim their thread is top quality thread and they sell them for years and come from a known factory... bla bla bla. Really? Who in the nowadays world is still buying that? In the end the customer has to deal with this stuff. I don´t know many US Mfg´s brands but I have some COATS Koban (now named Dual Duty) thread and some from Polyester from Synthetic Thread Co. Inc. in PA that is working very well. But most of the other thread I´m using come from German manufacturers mainly Ackermann / Aman (SYTON / SERAFIL & SABA) or some Gruschwitz (GETAFIL) - I have zero issues with this even sometimes quite old thread! So I really think a lot depends on the manufacturer. Buy thread from known manufacturers (google it) and not thread with just a "sellers label" and I´m sure you will have a constant quality and less thread issues. And I really would try some quality Polyester thread from a well known manufacturer instead of nylon. Some pictures of my worse thread spools - all this thread is working perfect and all come from known manufacturers.

-

Consew 277RFS Compatibility/ Parts

Constabulary replied to WoodsideCo's topic in Leather Sewing Machines

Very true Bob, but its always the very low price that is tempting and its hard to resist! -

Consew 277RFS Compatibility/ Parts

Constabulary replied to WoodsideCo's topic in Leather Sewing Machines

Thats globalization - hard to stop it. I really raised my eyebrow when I have seen the price and even incl. shipping. Maybe a production overrun that is flooding the market for a while - who knows. There is a lot of dirt cheap stuff coming from china. Not only sewing machine parts. We all know that and we still keep buying things from Asia, clothing, shoes - all kind of junk. Check your $100 Nike sneakers I´m sure they come from China. Guess where the $600 Apple Smartphones and the like comes from. You name it - and none of the end customers really knows the production conditions. A higher price does not necessarily mean the conditions are better - it just means often enough someone else is making the profit. -

Singer 29k171 "Another journey to the unknown"

Constabulary replied to jimi's topic in Leather Sewing Machines

The tip of the bell crank lever has approx a 5mm diameter when new. Maybe the newer 29K´s are still in use and pop up later on the market - who knows. Meanwhile my 29K71 produces approx 4.8 - 4.9 mm long stitches - can´t be much better. I figured when I put the stich lenght adjuster too deep (when the gib touches the foot) the stitches become slightly shorter again. So the longest stitch really is when the adjuster is just below the 5 mark on the BCL and have set it to the highest foot lift. That maybe be different on other machines - patchers sometimes can be tricky. -

Singer 29k171 "Another journey to the unknown"

Constabulary replied to jimi's topic in Leather Sewing Machines

gears are definitely worn off . Yeah - patchers can be a money pit - I invested more money in restoring mine than in any other machine I have! But on the long view its good to have one of the later 29K models since parts are most likely available for ever due to the Chinese clones. -

Consew 277RFS Compatibility/ Parts

Constabulary replied to WoodsideCo's topic in Leather Sewing Machines

or even cheaper They also show measures of the parts in their offer http://www.ebay.com/itm/New-Complete-Binding-Sewing-Machine-Attachment-Parts-Bracket-For-Pfaff-335/122140857437 -

Singer 29k171 "Another journey to the unknown"

Constabulary replied to jimi's topic in Leather Sewing Machines

What trip was I on - seems someone put weed in my x-mass cookies? Sure - the large bobbin usually is the the one with the 72 subclass I once have replaced some gears on a 29K73 I bought from CS but used and new gears did not play well together but it depends on the over all condition I think. Worked better when I replaced the small rack too. Dikman - usually the original (!) paint job on sewing machine is very resistant so when they are overpainted with some standard paint the chances are good the original paint survives when you use some sort of paint thinner. -

Singer 29k171 "Another journey to the unknown"

Constabulary replied to jimi's topic in Leather Sewing Machines

Really small hook? The 29K171 usually is a large bobbin machine. But your gear box really looks not as "beefy" as the one form a large hook machine. Strange! Maybe wrong badge on the machine? -

Manufacturer's Mark on Sewing Machine Hooks

Constabulary replied to Uwe's topic in Leather Sewing Machines

-

You don´t have to move the thread stand - maybe you misunderstood. Needles system it self is not too important as long as you have set up the needle bar hight correctly. The idea was that you are (probably) using 134 but machine is (probably) setup for 134-35 ~4mm longer than 134 or 135x17 ~5mm longer than 134 measured from shaft to thread eye. But when you have adjusted this it most likely is not the issue. My other thoughts I have posted in the earlier thread. Good luck.

-

Singer 29k171 "Another journey to the unknown"

Constabulary replied to jimi's topic in Leather Sewing Machines

WOW - how cool is that: A large hook short arm machine - my personal holy grale of patchers . Jimi, can you check if the the gear box has a parts number on it? What a great deal! The original baby blue color is for sure something you have to like but at least its the original paint and it seems to be in good condition! -

A Pfaff 145 / 545 manual should give you the instructions for threading the machine correctly - though they are flat bed machines the head and hook era are pretty much the same.

-

Glenn, thats right - I also have set up my Pfaff 345 for 135x17 as well. So the needle system could be a reason for thread shredding - so check your needle hook timing - maybe you have to adjust the needle bar hight. Happy New Year folks....

-

Techsew 810 roller foot

Constabulary replied to christiancowboycobbler's topic in Leather Sewing Machines

The "Singer roller feet" should fit the adapter but you probably have to adjust the presser foot bar hight. However, not sure if the combination of new roller foot + adapter are probably too long. As Darren said, I´d contact Ron @ Techsew. I´m sure he can supply the adapter and Singer roller foot too. Or maybe they have smaller rollers for the OEM roller foot. -

You never know what the previous owner has sewn with the machine - if the setup worked for his purposes it does not mean it works for your purpose. Because of the top tension - either reduce the bottom thread tension or try a heavier spring on the top tension unit. College Sewing has heavier springs - check with them when they are back on January 3rd. Not sure if this one is heavier as the one installed but I´m using it on my Singer 111 and other machines but they may have other heavy springs too. https://www.college-sewing.co.uk/store/B3114-232-000-BEEHIVE-SPRING-HEAVY-JUKI An occasional loop on the back (could) mean you are loosening the top tension occasionally or have too much bottom tension occasionally. You could also try a needle 1 size bigger like 150 or 160 (metric). Are you sure the hole in the feed dog is large enough for size 20 thread + 140 needle? Post some pictures of your tension unit and how you have threaded the machine and how the stitches look. Make sure the thread is coming off the the spool w/o hanging and the thread guide of the thread stand is centered above the thread spool.

-

Techsew 810 roller foot

Constabulary replied to christiancowboycobbler's topic in Leather Sewing Machines

Check minute 1.14 -

What exactly is the struggle with the thread? reg. stitch length - check this Video:

-

Machine is definitely a keeper. Well - I´m not 100% sure but the tension unit looks like one from a Pfaff 138. That does not mean your tension unit does not work with the machine but I think its not the original tension unit. Adler tension units look different they look like this: and yours has 2 tensions (thats for double needle machines, sewing tucks and so on) and seems you run the thread through both of them - thats basically wrong. Try to thread your machine a different way - go from the thread guide on top of your machine directly to your tension unit and thread it as shown in this picture and try again sewing.

-

Trying to figure out the basics

Constabulary replied to spectre6000's topic in Leather Sewing Machines

This is one of the most useless threads in the whole sewing machine section. I´d suggest deleting it as there is no sense in it tat all. Or at least close it with an Admin´s comment at it´s end. -

we also have dealers in Germany like Sieck.de or Frank Brunnet who sell Hightex (Cowboy) machines http://www.fbn24.de/epages/64180611.sf/de_DE/?ObjectID=34606502&ViewAction=FacetedSearchProducts&SearchString=441 Frank Brunnet also sells on Ebay and accepts offers: http://www.ebay.de/itm/Cowboy-Hightex-CB-4500-leather-sewing-machine-Sattlermaschine-/222356209782?hash=item33c5768076:g:3rIAAOSwstxVW6ak Since GB is still a EU member you don´t have to pay any custom fees.