Bert51

Members-

Posts

546 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Bert51

-

Elk Hide Gun Sheath

Bert51 replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Brian, sorry for hi-jacking this thread. Bert. -

tippmann boss - sewing thinner materials question

Bert51 replied to sombercrow's topic in Leather Sewing Machines

This is a picture I borrowed from the internet, but you can see the tension is showing in thread between the two hole post and the three hole thread tensioner and the thread before the two hole thread post. Bert. -

Elk Hide Gun Sheath

Bert51 replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I realise capital is a problem today, but if you can justify it then you will save time and thus money with the larger printer. I guess it would come from China, I am having heeps of problems with items posted from China at the moment, how long before your looking at upgrading? Bert. (being nosy) -

tippmann boss - sewing thinner materials question

Bert51 replied to sombercrow's topic in Leather Sewing Machines

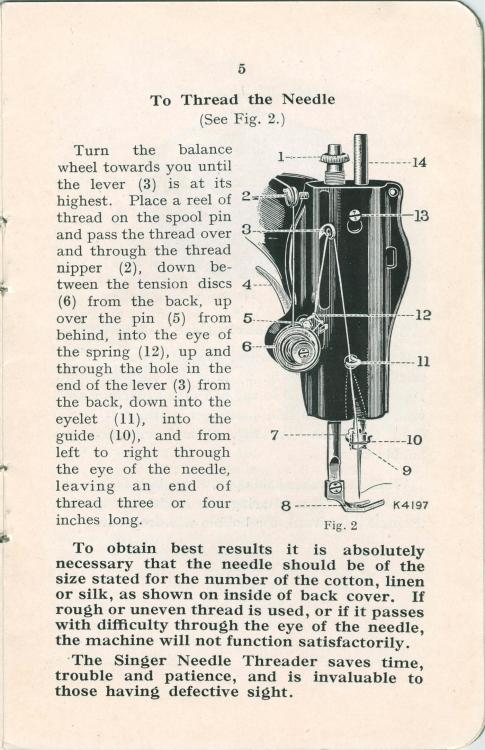

When you thread the post, you need to go through the first hole, pull the thread around to the side of the post you put the thread through the first hole so the thread goes around the post. Not like you have in the photo, but like this picture. Bert. -

tippmann boss - sewing thinner materials question

Bert51 replied to sombercrow's topic in Leather Sewing Machines

Thanks @Evo160K that shows what I meant. A lot of manufactures over many years have used this tension system. Singer and Adler have used it since the early days. It is basically a pulley that needs to be turned to create your tension, thus you need tension before and after the pulley to maintain your tension or it will give you mixed results on your stitching. Hopefully by threading the thread around the post it will give you the tension needed to stop stiff thread falling off the pulley. Bert. -

Elk Hide Gun Sheath

Bert51 replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Can you upgrade just the base or do you need to upgrade to a new printer? Bert. -

tippmann boss - sewing thinner materials question

Bert51 replied to sombercrow's topic in Leather Sewing Machines

Looking at your picture, I would try putting the thread so it goes around the the first post, that way it will give it a little bit of tension, as it goes through the two holes. Bert. -

Elk Hide Gun Sheath

Bert51 replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Now I see why you need the fringing guide. I like the colours. Bert. -

Necessary Adler 205-370 parts for leather

Bert51 replied to thecruffler's topic in Leather Sewing Machines

I have it's older brother an Adler 105-6 and all I do is change the needle from 214x1 to 214x2. They are a Nice Machine. Bert. -

I think you are right Lee, it is a 127. Bert.

-

Elk Hide Gun Sheath

Bert51 replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thant makes it look easy, I avoid anything with a fringe. I think you might find a good market for those. Bert. -

I think Bob may be right, I feel it's a 128. I have a 31K20 made in 1909 and it does not look like this one. I think the Serial is JC 404255 I cannot find a listing for JC on ISMACS I found a listing for JC serials on Google and it took me to a domestic listing. Bert.

-

Enjoy, it's a nice machine. This machine is well talked about on this forum, here's one posting you might find more information, Bert.

-

@RockyAussie Nice, very nice. Thanks, Bert.

-

-

Are we going to be sued?

Bert51 replied to LiftPig's topic in Gun Holsters, Rifle Slings and Knife Sheathes

If anything made of leather is "looked after" in a good manner it should last a life time, but if it is allowed to be knocked around, left in the sun and weather, then there is no way you could be held responsible for and damage to it. I have an old WW1 Leather box (first aid I think) and the only thing wrong is the stitching has let go and it is very dry and I do not think it has ever been looked after, I had to remove the wasp nest out to look at it. Do I have the right to blame the maker for using no rot and non UV thread? I don't think so. Bert. -

We are just starting winter here and will not see beautiful flowers like that for many months, Thank you Ferg. Bert.

-

I got the recipe from a friend who has been making it for me for years. The best I could get out of him is this. Put equal parts of Lanolin, Neatsfoot Oil and Bee's wax in an old saucepan and bowl like a double boiler, the Bee's Wax will be the last to melt, then add an equal part Pure Gum Turpentine. Pure Gum Turpentine is not paint thinning turps, it's like the turps oil painters use. I often vary the amount of turps, in summer I add less and in winter or if the wax is harder or if the Lanolin is to thick. I have found it is not a hard and fast recipe as the wax and lanolin can vary, plus if you have a very cold winter you need to use more turps to make it softer. After I make it, I place it in a jar before it cools, leave it for 24 hour, then push my finger into it, if it is to hard or to soft, I put the jar back into a pan of water on the stove and when it melts again, add more turps or more wax. I use it on canvas to water proof it, as well as leather. I have found, if I leave it to soak in to the leather, then polish it off it give the leather a nice shine and does not attract dirt and dust. I hope this helps. Bert.

-

Looks good to me. It's okay to put the Brake on work to take a Break, coffee that is. Bert.

-

Yes, they are brilliant, school of had knocks taught me not to sew them on. Take two and I did not sew the second one on, even better we have a couple of these pans. Bert.

-

I have similar trouble with a 20 M black that I use and I brought some nets from ebay, this is what I mean, https://www.ebay.com.au/itm/123985809830 Bert.

-

Pricing of Adler 5-27 with electrical motor?

Bert51 replied to Mocivnik's topic in Leather Sewing Machines

I have been a round a little bit in my time on this earth and here in Australia Adlers are not something you see every day, I do as I have a 105 in my collection, but I have never seen a 5 series Adler and I guess if there was one for sale the seller would be asking big dollars for it as he would say it is a "Rare" model. So I do not feel I would be able to give a ballpark price that would be any use to you. Sorry I was unable to help. Bert. -

I make my own leather balm for more then 20 years and before that a friend used to make it for me. I have never had stitching rot out or leather fail. If anything is have had a problem where it made the leather to soft it I use to much. I use it on everything I make through to my leather Motorbike Jacket. It's made up of Lanolin, Neatsfoot Oil, Bee's wax and Pure Gum Turpentine. If you where a bit closer I would give you some. Bert.

-

Pricing of Adler 5-27 with electrical motor?

Bert51 replied to Mocivnik's topic in Leather Sewing Machines

Sorry I am unable to help with the pricing as I know very little about machines in Slovenia, as I am in Australia, but I thought you might glean some information from this link or search the site yourself. Bert.