Bert51

Members-

Posts

546 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Bert51

-

Wow, now that is what I call thinking outside the box to find the solution. The handbag looks good from what I can see of it. Thanks. Bert.

-

All good Ross, I made mine many year back and found it to hard on my hands, that why I now own sewing machines. Your pictures are good enough if someone want to build a similar type of Stitching Horse, if I did not have one I would be asking more silly questions so I could build it like yours. I only hand sew small projects or if I want something hand stitch, you can't beat the look or feel of leather that has been hand stitched. Bert.

-

Those pictures show how very well it is made and I guess it would be very easy to use. Very nice. Bert. PS. Do you have plans available?

-

@Northmount I used to copy all of my images at 300 minimum and ended up with some old manuals looking to be very poor quality. I found that lowering Image quality to 150 or a little less help greatly in the copied image. Bert.

-

Just a thought for anyone putting magnets on their stitching clam. Many years back when I put the magnets on my stitching clam, I sat them flush with the timber,, they looked real nice, now the fingers are not as agile as they where, I wish I would recess them or sat them proud of the timber. Maybe I could have used weaker magnets? Bert.

-

That Tension setup looks very similar the the one Adler Aust. fitted to the Face Plate on my 105, it cost me nearly 200 bucks from memory. It has a heavy duty Bee Hive spring in it. Bert.

-

I am using Firefox and I got the same message last week, I had to click go to the site anyway and it stopped asking after that. Bert.

-

I have a Singer 29K58 and I believe the hand wheel on the front is standard for it. I purchased it from the original owners granddaughter and he purchased it in 1937. She told me this is the way it was setup from his shop. From memory all the pulleys and cog are pinned which I think makes it hard to get out of timing unless you have sheared a pin. Bert.

-

I have had good luck doing the main shaft like you have done, with a piece of pipe, but I used a dial gauge to fine tune it and I think you could get within tolerances with a gauge. Bert.

-

HELP! I was sold the wrong machine and I'm stuck!

Bert51 replied to JHBH2's topic in Leather Sewing Machines

-

jammed consew 206rb help suggestions

Bert51 replied to olivermarks's topic in Leather Sewing Machines

I have found a very small amount of Blue Tack (or similar) on the blade of the screwdriver helps holding those tiny screws to the blade. Bert. -

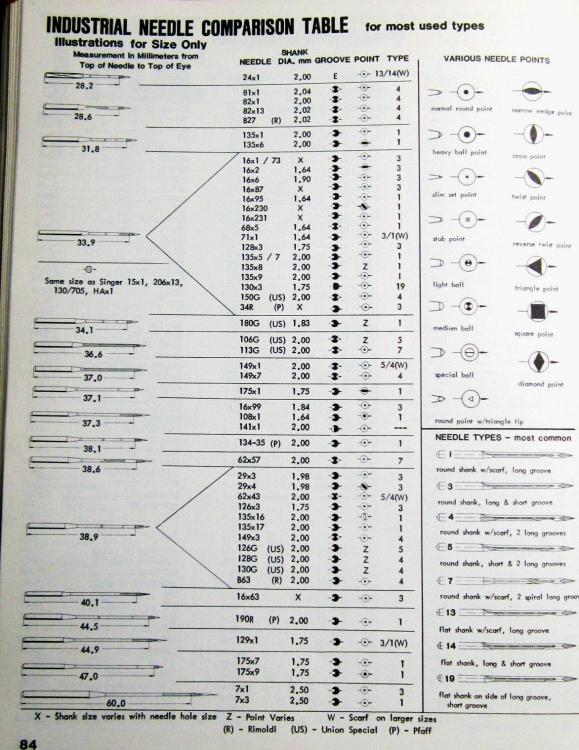

I have a Adler 105-6 and I believe that it is similar to your 5-6, to get information on old Adler's go to this site, http://sew24.blogspot.com/p/downloads.html For parts manual try this http://www.duerkopp-adler.com/commons/download/download-text-attachments/Vintage_Parts_Books_Adler/105.pdf For Operators Manual try this, http://www.duerkopp-adler.com/commons/download/download-text-attachments/Vintage_Manuals_Adler/Manual_Adler_104_105.pdf I love my Adler, it was my first true heavy machine and I mean heavy, I had to drive over 1000 K's to get it, stay over night and drive 1000K's home, well worth the drive. Bert. PS. I just realised you asked about thread sizes, I used needles from size 18 to size 30 in my Adler. Size 30 looks like a 3 inch nail. A member here has a good web site with good information and here is his needle and thread size chart. https://www.tolindsewmach.com/thread-chart.html

-

CB3200 or lower? Final decision/indecision

Bert51 replied to PALeatherArt's topic in Leather Sewing Machines

@dikman and I do not think you will regret buying it, ever. Bert. -

I acquired a 29K58 earlier this year and after a bit of work and few new parts I have a nice machine sewing just over a 4 mm stitch. I had to re-paint the treadle and now I have a nice looking machine that works I was lucky, I found no problem that I could not fix, I put it on casters so it is easier to move around, I put all my machines on casters. Bert.

-

Looking at buying a machine but overwhelmed.

Bert51 replied to Brigeyboo's topic in Leather Sewing Machines

All I can do is applaud you Wiz, You have always been straight with your comments and guide us to people who will help us most, without leading us astray. Yes we need our "contributing" members and with out their guidance some of us would be lost by now. Bert. -

Restoration for Juki LU-562 & upgrade to LU-563 Bobbin

Bert51 replied to Vinito's topic in Leather Sewing Machines

I just straightened the main shaft on a Singer 31K20, as I am not a hammer fan, I used a Dial gauge and a piece of steel tube about a meter long that fitted snugly over the shaft. It took many goes as I did not want to damage it by going to far and now I have a working machine, once i buy the other parts that where broken when it was dropped. Bert. -

Hmm, been guilty of doing that myself. Bert.

-

I don't think it is a treadle machine, I cannot see a treadle wheel on it? I have at least one industrial machine on treadle frame that has not been drilled and tapped for the treadle wheel. I have a 31K47 with this type of clutch and permanent running motor. See earlier post, Bert.

-

How do I mount a Singer Treadle clutch?

Bert51 replied to DelNeroDesigns's topic in Leather Sewing Machines

I run a Singer 31K47 with a permanent running motor and a similar clutch set up. As Constabulary said, the clutch goes under the table with the large pulley in line with the pulley on the machine, then set your motor up in line with the middle pulley of the clutch. Sadly I have not found any manuals or instructions for these units. I have found very little that is useful in setting them up or using them. Bert. -

I would love to see another of your write ups about this New Bigger printer and some nice samples. I might need to change my direction in hobbies or sell something, can't afford another hobby. Bert.

-

I can't wait to see what he can make with the new printer and a full report. Bert.

-

fit snap fastener with long part of a double head rivet?

Bert51 replied to ASAuLTCases's topic in How Do I Do That?

I purchased some long Marine stainless steel snaps that where a little to long for the job and found it hard to get them to roll down tight and not start to crush. It took a little bit of playing around and not to be impatient with the hammer and they still look good today. Bert. -

What hardware and tools to find at hardware shop

Bert51 replied to Kj86's topic in Saddle Supplies, Tools & Trees

There are a couple of members on the list from W.A., hopefully they will chime in when they can and help you. I still wish I was in the Pilbara. Bert. -

Do you have the manual, if not it is available here, http://sew24.blogspot.com/p/downloads.html Bert.