25b

Members-

Posts

707 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by 25b

-

I guess I've pretty much given up on this. I think what I'm going to do is just measure the finished height of these knots (for each different width of lace I use) and then log it all in one of my knot logbooks...that way, I'll know how big to make the foundation before I try to build the knot over it.

-

Yeah, I've seen Tim's videos and talked to him. He is a really nice fellow. I wish I had the time and money to go up there and try to learn as much as possible from him...watching him braid is mesmerizing. I do listen to what he's saying too though...I understand how to "raise" a knot from 5x4 to 7x6 to 9x8 and all...it is more difficult when trying to use the "special" knots to cover longer areas...i.e. the so-called "long cowboy knot"...have no idea how big an area it should cover. I know he said to just make the foundation and build the knot to fit it...that is a lot easier said than done, so...

-

http://leatherworker.net/forum/index.php?showtopic=57936

-

People have asked for sources of these on here often and from what I've read, you just modify round punches, like you said. Personally, I use washers, coins, or other similar things of appropriate diameter and just cut around them. Works quite well as long as you have a very sharp blade.

-

I appreciate you reply, but it doesn't really answer my original question... I want to understand how folks know how long their finished knots are going to be so that the foundation (knot plus tape, putty, etc.) ends up being the correct length for the knot that will cover it. Sorry if I'm not explaining it so that it makes sense.

-

What is "button string"??

-

That is an idea, but I dislike all the "goo" (for lack of a better word) produced by electrical tape over time. I wonder if gaffer's tape may work...it has less adhesive, so hopefully wouldn't get messy after a while. I was sort of hoping for something a little heavier as I would like for my braided items to have a little more weight to them...I guess that's just personal preference though... Thanks for your reply..

-

Sometimes (often) I have trouble trying to figure out how long to make the foundation of different knots. I've seen others use the 2-part epoxy putty stuff as well as leather or rawhide. But my problem is it is difficult to know what the finished size of the tightened knot is going to be, so that makes it difficult to know how long and/or thick to make the foundation under it. Any hints on this that anyone would care to share?

-

Learning To Make Wallets

25b replied to MonicaJacobson's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Yep. Glad to hear that worked for you. That's the way I've been doing it for a long time and it works great. -

Online Course On Leather Edges And Possibly Other Techniques

25b replied to seanafk's topic in How Do I Do That?

While I'm not in the least interested in these video offerings from others around, I would be interested in this. Please keep us posted. -

"quick Lock Buckle"? - Need Help There Please

25b replied to Aurelie's topic in Saddle and Tack Accessory Items

Never seen those parts available anywhere before. If you really need them, McMaster-Carr has stainless steel square tubing in 1/2" x 1/2"...you could easily cut several of these with a rotary tool. http://www.mcmaster.com/#stainless-steel-square-tubing/=vw9bbz -

PVA = Polyvinyl acetate...not "(Poly-Vinyl-Alcohol)" http://en.wikipedia.org/wiki/Polyvinyl_acetate

- 28 replies

-

- stiching machine

- stitch

- (and 6 more)

-

!help! Help ! Find Pattern Long Wallet !

25b replied to denisfilatov's topic in Patterns and Templates

Toproe: I am trying to locate someone to go ahead and make these. If I do, I will send the patterns to you. Tom: I am not really sure what your problem is, but I did not attack you in here (nor anywhere else, for that matter), so there is no reason for you to behave that way.- 36 replies

-

- pattern long wallet

- pattern

-

(and 2 more)

Tagged with:

-

!help! Help ! Find Pattern Long Wallet !

25b replied to denisfilatov's topic in Patterns and Templates

Yeah, good luck. Not going to happen anytime soon. I've pretty much begged for these and no one seems to want to (nor know how to) make the patterns and that was after me offering to pay a nominal fee to have them done.- 36 replies

-

- pattern long wallet

- pattern

-

(and 2 more)

Tagged with:

-

I ordered a double shoulder from a different company (I will not buy from springfield anymore due to their shipping profiteering and other reasons) and the shipping was around $8.00...and this was about 3 months ago...not years.

-

!help! Help ! Find Pattern Long Wallet !

25b replied to denisfilatov's topic in Patterns and Templates

I've tried many times in the past and cannot do it. That is why I'm hoping someone on here would be able to make these, but I guess they're just too complicated or something. Anyway, thanks a lot for your insightful, enlightened post.- 36 replies

-

- pattern long wallet

- pattern

-

(and 2 more)

Tagged with:

-

!help! Help ! Find Pattern Long Wallet !

25b replied to denisfilatov's topic in Patterns and Templates

Ok, I read Tom's post a couple of days ago and this is clearly not going to happen anytime in the near future. (I am not upset - just stating facts, so don't read anything else into that please.) Is there anyone else that would be kind enough to make the patterns for these? I would consider paying a nominal fee for the patterns, if that is necessary. Again, I will not be selling them or anything like that. I would just like to make some of them to give as gifts to my friends and family. I actually wanted to do that since Thanksgiving, but couldn't because I didn't have the patterns. Thanks for any help.- 36 replies

-

- pattern long wallet

- pattern

-

(and 2 more)

Tagged with:

-

Uhh...I sent you a PM about this already.It sounds like you may have never seen the parts of these snaps before they're assembled. The "dimple" is already on the snap when you buy them. Also, the dimple isn't the part that makes it a directional fastener...they're made differently inside -- the "dimple" is just there so you know which direction to pull to unfasten it. The press-n-snap dies aren't terribly overpriced.

-

I get payment upfront on all custom orders. This eliminates the problem of the customer suddenly not being able to pay for the custom item they ordered once they're finished. The downside is they will nag you to death with "AREN'T YOU FINISHED YET????" questions constantly. That's even after I've already given them a timeframe of how long it will take to make their item...they don't care. My favorite is when they order a custom item, make me wait two weeks for them to pay for that item...then they want it done and shipped the day after they pay.

-

Not trying to tell you how to run your sale, but you might want to have another look at your decimal point there...I don't think it says what you might've intended.

-

Bookbinding And Hot-Foil Stamping Questions

25b replied to Wilshire's topic in Leatherwork Conversation

That's because his name is ATKINSON...not "Atchison". Here's the link to his youtube channel... https://www.youtube.com/user/satansbarber ...and yes, spelling makes a big difference when searching on youtube and google. -

From the album: wallets

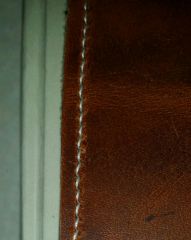

...inside of the exact same stitch line from the previous pic... -

From the album: wallets

Outside of my most recent Horween Field Notes cover... -

Bookbinding And Hot-Foil Stamping Questions

25b replied to Wilshire's topic in Leatherwork Conversation

Do NOT go to talas.com!! The correct site is talasonline.com. The "other" site is the type of site infamous for installing malware...just fyi... -

Advice Wanted On Pricking Irons/stitching Awl

25b replied to Grey Drakkon's topic in Leatherwork Conversation

Yeah, that was me and leathercrafttools.com *is* cheaper both in their prices for their items as well as shipping...but don't just believe me. .go to their website and check it out for yourself. Most of their tools are the same brand but are a lot cheaper and so is the shipping. Leathercrafttools.com doesn't get you stuck for Customs fees either, so...