-

Posts

5,248 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dwight

-

Depending on your "budget" . . . you have a lot of options . . . I started out with a Tippmann Boss . . . which I still have . . . and if I was buying another machine of the similar line . . . it would be the one I'd buy again. A 42 inch belt takes me 20 minutes . . . about 8 or 9 minutes per side . . . with a coffee and arm stretch break when I hit the tip of it. I've got a Cowboy now . . . and we're down to something like 6 or 8 minutes on them now . . . just taking my time . . . I hate "do-over" jobs. May God bless, Dwight

-

Ummm . . . just between you . . . me . . . and the gate post . . . I do like that saddle. I could get right real happy hopping up on El Diablo . . . and heading for the back 40 on that. May God bless, Dwight

-

You did good my friend . . . better than I for sure . . . If I had to hand sew belts . . . I'd go back to concrete work . . . never did one that way . . . don't plan on it. May God bless, Dwight

-

Fiebings Burgandy

Dwight replied to AlZilla's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

I've had fairly good success with it in the few times I've used it. It's very similar to the dye used by a bunch of cheap leather makers. Local guy had me make him a new belt . . . he outgrew his old cheap belt . . . he passed before he ever came to get it . . . so I got his ammo from the old one . . . plus two belts one day I'll put on Ebay and sell. His old one was that color . . . new one matched the holster really well. May God bless, Dwight -

Y'all aint never gonna see my first one . . . May God bless, Dwight

-

Belts is a "to each his own" . . . which incorporates the customer as well. Many of mine carry heavy guns and other stuff on those belts . . . they don't want them bending and twisting out of shape . . . and the bulkier belts make that happen longer than a fat single layer belt . . . or a thinner double layer . . . at least that has been my experience. Plus I also make a steel lined belt that is even more adept at not bending and twisting . . . May God bless, Dwight

-

Mine are generally in the .180 to .220 inches thick when it is done. Starts out as Tandy leather 7/8 oz . . . same thickness for both pieces. Toward the ends of a side of their leather . . . it is usually a bit tougher leather . . . so I make the buckle end out of that tough leather . . . and it is only one thickness . . . the outer leather. It then folds nicely back over . . . gets two Chicago screws and a buckle and a belt keeper. Have never in over 20 years had a belt "wear out" in that buckle area . . . or have problems slipping thru belt loops or buckles. Truthfully never saw any sense in a double layer attached to the buckle. Jus the way I do it though . . . and it is not universal. May God bless, Dwight

-

Hey, Handstitched . . . those are both really good looking pieces of work. Belt is a tad flashy for this ol preacher . . . but I'd make one for a friend. Anyway . . . if I were doing either one . . . I'd go back to my original suggestion . . . a drum sander for the martingales . . . and a band saw for the belt. OR . . . that little 30 inch belt sander that Amazon sells https://www.amazon.com/EX-ELECTRONIX-EXPRESS-Mini-Sander/dp/B004D96ZCG/ref=asc_df_B004D96ZCG/?tag=hyprod-20&linkCode=df0&hvadid=309735728871&hvpos=&hvnetw=g&hvrand=8573954697880619670&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9014870&hvtargid=pla-521860277467&psc=1 It'll do the trick for you in short order. I've got two of the little belt sanders . . . one is used in the leather shop . . . other out in the wood / metal shop. Noisy little rascal . . . but they do the job. May God bless, Dwight

-

If I did that . . . I would do like Alexis mentioned . . . make a pattern. Make the full size blank . . . trace the pattern on it . . . and if they are shallow . . . make the indentations with a drum sander. If they are deep . . . cut em out roughly on a band saw . . . then run them thru the drum sander . . . should make a nice belt. May God bless, Dwight

-

The main thing I found . . . and it will be a deal killer to a large number of people . . . Your pictures are way, way, too big as far as megabytes are concerned. It took well over a minute for the first page to load . . . That first page picture should not be over 500KB . . . and my guess it is 10 or 12 megs. It should load in not over 10 seconds. People will not generally sit and wait for pictures to populate on a website they are going to for the first time . . . especially if it us just another "unknown" site. A 500 KB picture will give all the detail anyone needs to determine if they are going to do business with you. May God bless, Dwight

-

Welcome to the club . . . don't feel alone . . . if it weren't for my Samsung Galaxy and Adobe Photoshop Works . . . my website would be a few words and that's it. Mine is very generic . . . dwightsgunleather.com . . . you are welcome to take a look at it. May God bless, Dwight

-

I only put one per end . . . as I put the blank end on a red paper eraser . . . and seriously push down and screw tight with my screwdriver on the other side. If I can . . . I try to talk them into a woven . . . 4 hole . . . leather thong. THEY don't come loose. Never had one come loose yet . . . and when I've gone back to change something . . . it has been a pain at times. May God bless, Dwight

-

ProPaste epoxy glue

Dwight replied to dikman's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

I had my favorite coffee mug in the shop . . . a board knocked it off into the tractor . . . and into pieces. Good ol epoxy saved the day because it was just a few pieces broken . . . not fully shattered. We laugh and call it my "integrated" cup . . . but the integration has proved to be good. May God bless, Dwight -

Good job . . . I always wanted a small finish carpenter's hammer with leather handles . . . never got one . . . May God bless, Dwight

-

What weight vegtan leather should I use for a sling seat?

Dwight replied to mcbecklesworth's topic in How Do I Do That?

McBecklesworth . . . would you do us a favor here . . . we've got some folks on here that seem to think it takes 20 or 30 oz leather for a chair seat . . . or something nearby. Have someone seriously measure the thickness of the leather . . . and tell us in decimal inches just how thick it is. I've sat in too many of those years ago . . . and they were not thick leather seats. May God bless, Dwight -

What weight vegtan leather should I use for a sling seat?

Dwight replied to mcbecklesworth's topic in How Do I Do That?

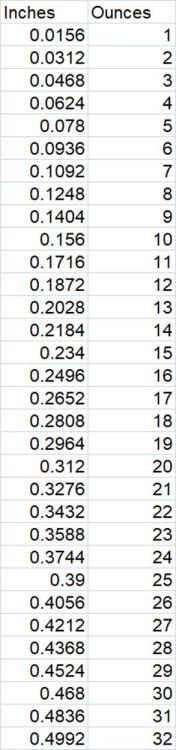

Just take a micrometer and measure the thickness . . . measure all three pieces to make sure they are the same. The thing to remember is that 1/64 th of an inch is 1 oz leather . . . the chart below will help you decide. My guess from persona experience in times past . . . this will be in the 5 oz to 7 oz size range. Thank you by the way . . . for the good memory. It has been years since I sat in one of these . . . rocking on the front porch . . . watching the world go by. When some of our folks could not afford leather . . . we cut up one inch wide strips of inner tubes and wove them to form a seat. They were really comfortable if the owner wasn't say a 300 pounder . . . lol. Would sure like to do it again. May God bless, Dwight -

Pampeano Belt - How to punch pattern for stitching?

Dwight replied to CJJ's topic in How Do I Do That?

I wouldn't wear one to a dog fight . . . May God bless, Dwight -

Well, Doc . . . here is the real deal. As you can see . . . paint is long gone. Box like thing at the top is a package that once was full of the razor knife blades . . . laying side by side . . . in a decade plus years . . . I've used 2/3 or so of it. You can see the full size blade . . . with the broken one above it . . . done with 2 pairs of pliers. The "standard" blade that ain't worth a crap . . . cost I think 10 bucks . . . and could never be sharpened past screwdriver end sharpness is there rusting away. Anyway . . . this is my tool . . . works like a champ. May God bless, Dwight

-

Yes . . . I've used it successfully on leatherwork. Too expensive to use on a large scale though. May God bless, Dwight

-

Yeah . . . what he said . . . ^^^^^^ I have made "boxes" that hang on the belt carrying .380's . . . and the like . . . but when the flap comes up . . . the hand can grab the gun . . . and it's game on. I think the coroner would ID the body as having been a CCW licensee . . . and he had a cell phone. May God bless, Dwight

-

Stitched patchwork leather pieces for sale - Great for a project

Dwight replied to PaulineSul's topic in Old/Sold

That is some beautiful work . . . time consuming as well . . . I sat here and looked at the red / black / white diamond pattern and said to myself I'd love to have that . . . but I have no idea what in the world I would do with it. Hope you find folks who can take the second step . . . May God bless, Dwight -

You should have put the belt on . . . and marked the belt either next to the first belt loop on the left side . . . between 1 and 2 . . . but next to 1 . . . OR . . . just before you get to the last belt loop on your right side. It should not have been attached to the tongue . . . but rather the belt itself . . . and about as high as you can get it. As you presently have it . . . it will be a total pain to get thru the belt loops . . . and will hang down in front . . . and be uncomfortable. But it is a good start. May God bless, Dwight

-

My brother in law gave me an aluminum strap cutter some 10 or 12 years ago . . . I buy drywall razor blades . . . snap them in half with two pairs of pliers . . . use those blades till they get dull . . . break a new one and I'm good for another month or so. Works for me.. . . . (this is not mine . . . but is the same type . . . . black paint is long long worn off . . . left side is slick and shiny from all the leather passing by it) May God bless, Dwight

-

That's some good lookin work . . . on a good lookin rifle. I've a .22 in a similar stock . . . bull barrel . . . bipod . . . it'll do little one inch circles at 50 yds if I do my part. Yes . . . those friends are few and far between. Am I correct that you may be doing some rat shooting?? May God bless, Dwight

-

It's a whole lot easier to make a flat backed pancake . . . you can get almost the same look . . . especially the tooling. OR . . . you make the holster . . . the back of it will be sewn to the belt loop piece . . . then folded over and the side seam sewn . It is some tricky sewing . . . and I really don't think this one was done that way . . . but the T nuts and screws will ALWAYS allow the holster to flop . . . and if you are not up to a floppy holster . . . (I'm one who can't stand it) . . . then ya gotta sew the thing. May God bless, Dwight