-

Posts

3,265 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by RockyAussie

-

Sewing a lining into leather bag - help needed

RockyAussie replied to jakc3's topic in How Do I Do That?

Nice looking machine and with the needle positioning system you should be going great in no time at all. It is a shame you have to cut out a large section of that nice table for your bag work to get the clearance. I switch a lot between the 20 and 40 and 60 threads and I keep separate bobbin cases for each to cut out the need to adjust the bobbin spring each change time. Have you got a bell skiver machine yet? Regards Brian -

Let us know how you go.

-

Yep that should work fine but don't let the blade get near the glue layer of course. Note: make sure that the to be wasted piece is very even in thickness or your thin piece will vary similarly.Have you tried the thicker piece without glueing? I do that sometimes but with a longer piece due to the top going in faster than the bottom piece.

-

Do you have to get the contacted pieces apart after it is split? They would be well pressed together and I would expect a lot of top surface damage. The site MonicaJacobson mentions advertises the Dublin and Essex as well. Regards Brian

-

I hate to say it but even with my best band knife splitter i have unreliable results if trying to take off any less than .3mm. A bell knife skiver can do pretty good for splitting if you have a good one and know how to set it up well. Failing that maybe consider this alternative below. It is a Multi tool sander I have modified for heavy sanding purposes mostly. Best of luck.

-

A thicker piece will enable you to get a thin piece thinner but why would you contact cement it? Would you not have trouble getting it off? Why not just use thicker leather to start with to split? Maybe your last sentence has somethin in it?

-

Thanks Bob, That's a lot of floor space to have for something that looks like it doesn't cut right through that well. I doubt it would be much quicker than my clicker press cutting and the rough cutting edges left would make many products pieces more trouble to fix up later. I presume it is a swivelling knife cutter that if set deeper would eventually tear up the cutting surface.

-

Sewing a lining into leather bag - help needed

RockyAussie replied to jakc3's topic in How Do I Do That?

Hi again jakc3. What sort of sewing machine are you using? -

How is the cutting done MandyChai? I can not see any link.

-

Hey Dikman sent a pm with post tracking number. Regards Brian

-

Very nice looking work gigi. I have no worries with doing my belts without folded edges or stitching with the contact glue and the edging I use. I have to go get dinner or wife will kill me but see belt as I make over a 100 per week and have no problems with. The glue can be sprayed or through machine or brushed on as see pics.

-

Do you not mean, a lining that does not come off at the edges? Sorry I am confused.

-

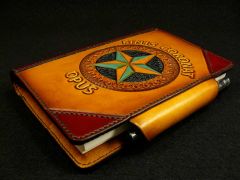

Customized Book Cover

RockyAussie commented on JustKate's gallery image in Our Leatherwork Galleries

-

Just finished this possibles bag

RockyAussie replied to dhaverstick's topic in Historical Reenactment

WOW that is a lot of very nice stitching. I hope the jewellery your wife got is very good. I guess that is turkey feet burned in under the flap. I hope his feet didn't get too hot. Great work, hope to see more. -

Hi gigi, myself I use a solvent base contact glue which is commonly used in the shoe repair trade for attaching soles. The edging is also very good for not separating apart. But I would still prefer the stitching for extra security and the band above was done as a prototype to arrive at the desired shape and structure.Here see some ostrich watches and bands I did a while back and they are folded edge. I would not dream of using this method without stitching.The face skin I had to split down to .3mm and the failure rate was pretty bad.

-

How I would tackle it is in the following link. should help

-

Sewing a lining into leather bag - help needed

RockyAussie replied to jakc3's topic in How Do I Do That?

Looks good jakc3. The handles turned out very well and the double line stitching to attach them worked out very nice as well.I presume it was all stitched by hand? Outer edge zip stitch with machine would be easier and easier to keep out any wobbles in my opinion for whatever that is worth. Hope to see more of your work in the future. -

Hi Dickman If you want to pm me your address I'll send down a part roll of Strongbond for you to try if you have not already. I know it will work unless your machine is wrong. If you want more then I could arrange for them to ship to you on my acc. Regards Brian

-

Very good edging for colour white Victor. I do not normally take pictures as I go if at all but here are a couple. One is done for a prototype watch and this was the first leather band I did before the crocodile ones. The other is just black croc with thick inner padding.

-

Using soldering iron on edges of leather

RockyAussie replied to the gafer's topic in How Do I Do That?

What Gary recommended should be ok but for about many years I've been using Ares (Italia) S.r.l. For black mosty LC/ZCD and The clear I mix my pigment in to give me the colour range I need I use AR 6350 Neutro denso lucido. (see link)http://www.aresitalia.info/ares/index.php?option=com_content&view=article&id=136&Itemid=172&lang=enThese are I believe the same as the Fenice paints as available from Campbell Randall in the US. They also have a temperature control soldering iron I think. I have used a 80 watt soldering iron with a groove I ground into the tip for about 20 or more years. This is just something I worked out for myself as I had not seen or heard of these filituse things until recently. I have always just used a light dimmer switch that I build into a wooden box to temperature control. They last for generally 5 to 10 years at a time. My method roughly goes depending on the thickness and leather etc like so. Get the shape sanded in first and sometimes heat away the fuzzy bits with a paint stripper gun. 2- Two coats of edging. If really rough sand a bit with foam sanding block.3 - Run the iron groove down the down the edge pulling in toward the centre from both sides and one down the middle to get rid of any peaking or grooves. 4 - Give a grey scotch brite wipe over if still a little rough. 5 - Finish of with 2 or three coats of edging. 5 wax polish. When the edge is thick it will take more work and more coats and when thin less. -

Fantastic work Aika and I checked out your belt making also. There is going to be one hell of a lucky man out there for you I reckon. Maybe there's one in Australia. There is certainly a job waiting.

-

Bangle sanding pics as promised. 1st pic stiff and not sanded - 2nd pic setting for thickness-3rd sanding the croc - 4th results after sanding - 5th check for size - 6+7th stitched up - 8 ready to be glued up. Thankfully the matt ones I can split ok and they are twice as fast to fold and glue down. That's all for now I still gotta do another 50 or so yet. Regards Brian

-

I am Looking for 1.75"(45mm) buckles that are well finished for my belts. If you can get samples I am wanting around 100 per month. 200 at a time 100 Nkl and 100 polished brass. Let me know if a goer. Brian

-

Are you talking to someone JLS? ..........Ha Ha That's all the point on coming to this forum.

-

Yes it is please see the link and if you check it should lead to where in the US it can be bought. You would need to lathe back the back drive wheel outer rim in order to make the belt removal possible if you want to shroud it as I have done. http://www.multitoolaustralia.com/products.html Regards Brian