-

Posts

3,265 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by RockyAussie

-

Manufacturer's Supply Company Bell Skiver Project

RockyAussie replied to mcguyver42's topic in Leather Machinery

That is what I was afraid I might see. Without picking up another head somewhere I think it will be pretty hard to get going but that said ...the vacuum part and table of it could be worth an easy $200+. If here in OZ I would pay that and more. IF you could work in close with one of the dealers and if one is close by then you may be able to find some compatible parts.- 20 replies

-

- leather paring

- bell skiver

-

(and 1 more)

Tagged with:

-

Manufacturer's Supply Company Bell Skiver Project

RockyAussie replied to mcguyver42's topic in Leather Machinery

It has some similarities to a Fortuna skiver but I can not see from your pictures how the sharpening stone can be driven. Normally there is a belt that feeds inside through the machine and that hooks over the back right pulley set up. Some other machines run off a clutch that is on the right front pulley but I see no front control knob to actuate it. Otherwise I see a fair bit to do but the part that worries me most is that there is no cover over the back gearbox that transfers the motion to the feed roller. If you turn the back right pulley clockwise by hand does the feed stone revolve alright? The bell looks to have plenty of metal left so that's good. The left cover that is missing should not matter to start with. I will try and load up a pdf file that may be to large as that may help a little. Best of luck.Fortuna 50 p ag.pdf- 20 replies

-

- leather paring

- bell skiver

-

(and 1 more)

Tagged with:

-

Help! Rolled edges: Made a thing, not happy.

RockyAussie replied to YinTx's topic in How Do I Do That?

I would be doing a binder edge either fabric tape or leather if you prefer. I am not sure but you may have come in a little too far from the edge when connecting the gusset to the front section. 1/8" in would be my guess would work best which I think would make the gusset area not stick out so much. NOT to bad overall though.. -

Sometimes I use a vinyl and sometimes along with backing with stiffeners but having some cheap real leather is the best way to go. If you know that you are only using it for pattern work prototyping you can normally pick up crappy leather that nobody wants to buy for a giveaway price. If he is close enough call @nstarleather or email him as I think he may be able to help nstarleather@shtc.net

-

when you have it set up and working and you are familiar with how to get it to print let me know if you need some help. I would be happy to do that for you. Show me the type of product you want to do and any ideas of the pouch design and I will do my best. The customer is very pleased which is always a +. The tabs I have not done before but for doing a lot in a day it was the best I could think of and so far it works well. For those into 3D printing ....the tabs are solid and done in 2 parts then glued together. This is to give the best strength to the pressure pull on the tab. The other parts are 2mm walls including top and bottom with a 30% fill. All up this one chewed up about 700 grams. Took longer to print than it took me to design.

-

This video shows how I have made up a 3D printed mould with retaining clips for wet moulding a pliers pouch. The customer for this job wants to cast up to 28 pouches in a day which will require a few moulds to allow some drying time in between castings. This is also why I designed the retaining clips to allow for a quick clamping method which would not require any extra hardware to be used between castings. This is my first prototype version at the moment and I will try and do up a finished pouch by Christmas. If you do any pouches on a repetitive basis and would like to know more contact me. Follow my channel if you want to see more on how it is made.

-

Doubt it will help by other comments on this page but I have to say that like a lot of stuff these days the whole world just seems to be going nowhere very quickly. https://www.facebook.com/theupsstore/

-

What makes the Techsew 4800 a Godzilla vs Cobra 26 ?

RockyAussie replied to luckystudio13's topic in Leather Sewing Machines

For most stuff I make I need the narrow needle plate set and if you got a fair bit of time to spare for reading this post will show and tell why - While you are there if you check the video and have a look at my other videos on my channel you can see also a few on a Cowboy CB6900 which I believe the Cowboy people over that side of the pond call a Cowboy 1341 or the Techsew people call a 4800. This is just one of the few - Note I think it is a great machine for wallets and bags but it would not be my personal choice for heavy duty knife pouch and holster work. -

What makes the Techsew 4800 a Godzilla vs Cobra 26 ?

RockyAussie replied to luckystudio13's topic in Leather Sewing Machines

On some machines that would be true but for certain not with this model. Slow or fast the oil feed is happening. The 4800 has a square drive feed that means you have a more reliable consistent stitch length when going over thick and thin sections. -

It may help also if you have a picture that shows the non binding kit pieces. I have both a 335 binder clone and a similar one that is not with a binder but there are quite a few differences such as the feed dog being able to reciprocate instead of only going back and forth,distance of the needle hole position from the end etc. The hook and perhaps the feed dog may just need to be moved to line up correctly (left or right) but I cant think why the timing would need to be changed.

-

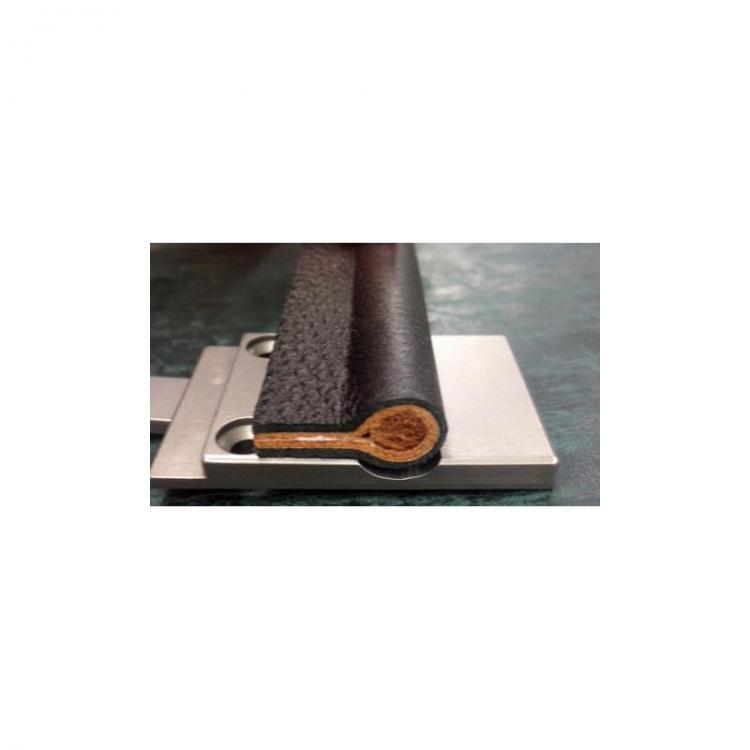

I have a bit of an odd shape knife here and I have not done a pouch for one like this before. I am wanting to stitch 2 lines around the outside edge but it would be nice if I did not do any stitching on the fold over I think. Because of the welt I am thinking i will have to do at least one line there. Do you think that would look alright? or should I do 2 lines all the way? This picture is to show how the welt goes fully around -

-

That is so sweet of her. You should show your gratitude and repack the refrigerator so that every thing is sorted by date and size. Oldest to the front of course. Make sure your smiling with an expectant approval look when she opens it up. My missus packs up my mess she calls it and when I go searching I find drill bits and screw drivers and pens and all sorts of stuff with no particular apparent arrangement at all.

-

I have a Fortuna , a FAV AV2 and a Cowboy 801 and they all are good but I have to add that the Cowboy one is supplied in this case with a vacuum extraction and a second motor to run the bell separately. Chrome or veg no problems. All of these machines are with a vacuum extraction and I would advise to get one that way as it helps a lot with the softer leathers to stop the split waste coming up on the feed stone and wrecking the leather you just skived. Other thing I would advise is getting a roller for the presser foot as that makes most jobs run through easier and in particular thick veg stuff. If you check out my youtube channel you will see a few videos that can help like this one -

-

Applying "Lining" over Round, Bulgy Surfaces

RockyAussie replied to Hardrada's topic in How Do I Do That?

Yep that goat skin does not look that friendly for the job. Once you have a good pattern does make it easier but in order to get that I would do the following. Lightly glue the goat onto the top only temporarily only gluing the top section at this stage. Then with a slicker lightly push down the sides to find where the leather can have any surplus taken off at the edges. Do not leave longer than needed. Do the same as best you can around the tip and corners and mark to cut off. Pull the goat off of the veg and skive in 1/2" or more if possible and keep it thin. The thinner you make it the less you have to try and condense later. You can see where I have done something similar with a very long 8 1/2" folding knife I did some time back in crocodile. Croc does have a slight advantage at not showing the condensing as much sometimes. When you have finished the skiving do another push on test and trim some if needed. Try not to apply with using the top mould as you can pull and push better without it getting in the way and keep in mind not to pull and stretch the leather too much as you go. Work your way down by going down in small steps from the top and dont let any touch the bottom flick out until you have all the edges to the bottom. -

Applying "Lining" over Round, Bulgy Surfaces

RockyAussie replied to Hardrada's topic in How Do I Do That?

Would you be able to post a picture of the part that is giving you trouble? Above you say lining and I am trying to get what the problem is. If it helps any I can generally get most stuff to work with a pointed bone folder and a pointed end bolt where things get really tight. As much as possible let the leather flow into place rather than trying to stretch it too much. -

This is a video I just made showing an old air driven rivet press I have set up for cutting the ends of a large quantity of belt strips. In this case I only needed to do a square end cut so I used a piece cut out from an old clicker knife pressed into a piece I lathed up to fit the press. I believe it could be suitable for quick hole punching and shaped end cuts as well.

-

Not true at all. A compressed sole leather for a shoe is about the only veg leather I would hesitate at skiving but for that I would soften the area I wanted to skive by soaking it first. A sharp bell knife and a roller presser foot will handle any veg you can like. This video I made about 3 minutes in shows a very hard veg piece being skived and in this case I could have set it up a bit better than I did. It was an afterthought on the run at the time -

-

Even if you have the machine threaded with tension not right the hook would normally still catch the thread. My first place to look is to make sure the thread is not wrapped around the needle when you start and that the needle groove is directly to the left. If the needle groove is too far forward or backward then the loop that gets formed can be missed by the hook. A lot of the time people put the needle in the wrong way around and that is way too common a mistake.

-

Thanks for that picture. Many different brands often have copies from the same casting and a bit of a google search showed some similar types that more than likely share the same M style I think boobin and case . This Mitisubshi looks right https://www.ebay.com.au/itm/264933835667 And this Highlead as well - https://www.highlead.co.uk/highlead-GC0318.html If you measure the outer diameter and ask any machine parts suppliers to confirm I think you will find what you need alright.

-

I tried looking online for anything on a Ferdco pro 84 and could not find anything. Would you be so kind to post a picture of yours machine here?

-

-

Yep I reckon so, I gotta be careful the wife doesn't catch me looking at this stuff these days too much. I am thinking about it but what diameter size would be best to start with is the question? 1/2" or 5/8" you mention but would this apply on such a large machine with normal leather point needles and thread? How round are the round reins on average I wonder along with other horse related gear? I will have to start my own post with this question I guess. Sorry for going off topic to the OP

-

-

-

Just drinkin mine now..... This is not the best video to show how I do something similar. At about 30 seconds in you can see a bit of how I do it. I think that a cut down blanket foot and and centre foot that is not the open toe type it would be possible if you are game to grind them back. On the blanket foot you have to grind back only enough for it to ride up tight to the swell. Only the part in the middle of that foot at the back will be doing the holding. I did have to grind the needle plate slightly off on the left edge to stop the swell pushing against the feet. https://youtu.be/1xy8efhw1U0