-

Posts

183 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by CastleLeatherWorks

-

I would only recommend to use thinner leather. i like to use 1.0/1.5 oz leather to keep things from getting to bulky but i also make my wallets fully lined so it doubles up the thickness in some parts.. also skive all the inner pockets to reduce bulk wherever i can. it works for my style but i try to make "higher end" looking items as opposed to the crafty style alot of people are into.

-

Thank you!! Yes buttero does scratch very easily but I like the way it wears. I just got this mpg Apollo from district leather supply that is supposedly better than buttero but I haven’t cut into it. The stitching is 5mm instead of my usual 3.38mm because I was feeling lazy lol and while I do agree it’s wider than usual I think it still looks very nice.

- 11 replies

-

- linen thread

- buttero

-

(and 4 more)

Tagged with:

-

Thank you !! initially that was my plan full aragona and somewhere along the lines I decided to go with black. I have plenty more so I’m sure I’ll revisit this.

- 11 replies

-

- linen thread

- buttero

-

(and 4 more)

Tagged with:

-

Back with another wallet. I really like the way this one came out. The mpg Aragona has a beautiful pull up when flexed. I did apply a layer of Aussie leather conditioner to it and it turned the leather darker than I would have liked but I think it still looks great and feels nice in the hand. This one is black buttero for the outside wall and inner money pocket with mpg aragona in charcoal for the inside. Hand sewn with 0.45mm black waxed linen thread spaced at 5mm. Edge paint is uniters black. comments and critiques always welcome thanks for looking!!

- 11 replies

-

- linen thread

- buttero

-

(and 4 more)

Tagged with:

-

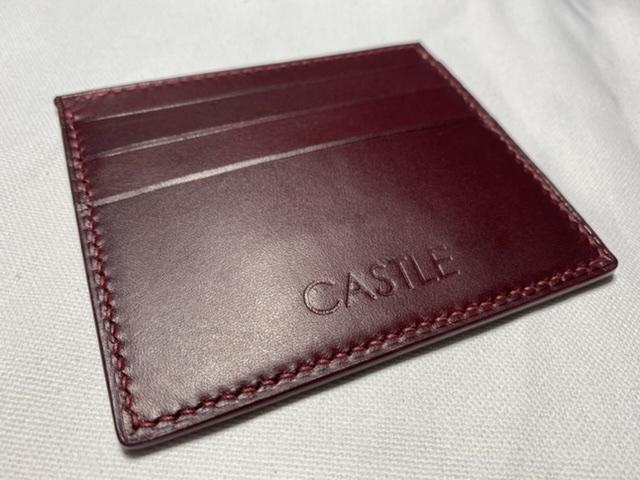

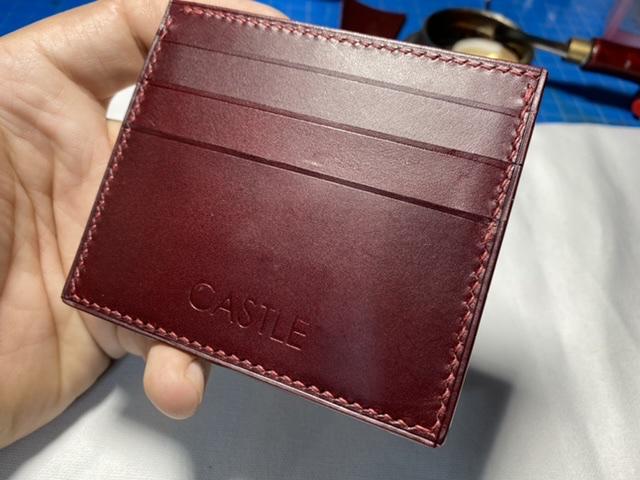

One of my most recent customer projects 6 slot card holder in burgundy buttero. Fully lined inner pocket with turned edge. Hand stitched with burgundy waxed linen thread spaced at 3.38mm..edge paint is fenice burgundy. comments and critiques always welcome =) thanks for looking!!

-

St. Bernard dog collar

CastleLeatherWorks replied to CindyCLewis's topic in Collars, Cuffs, Leashes and Leads

Looks very clean and well executed, if i had to make a criticism i would say the stamping could be more pronounced or maybe its the color of the leather not allowing me to see the depth. other than that i cant think of any thing else lol so great job ! that wooden barrel is sweet. Post a pic of this on the dog if you can !! -

i applaud your efforts. i dont make holsters so i dont know the challenges , but just from looking at your work i would like to offer some advice from a purely leather working perspective. 1) work on your stitching. try to keep your stitch lines as straight/even as possible also thread looks way to thick in my opinion.. did you use pricking irons or an awl? 2) your edges looks very rough. have you considered sanding and burnishing them. i believe it would improve the overall appearance of your holster. 3) what is the purpose of the extra stitches around the border? if they serve a purpose i would try to make them as symmetrical as possible. Hope i don't sound to harsh. just trying to offer some advice to improve your finished product. Take care -

-

DRKRM - Mini Arm Bag

CastleLeatherWorks replied to GinBerlin's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

the work and design look nice so good job on that. it is very simple and clean. i don't see much use for it though. maybe it would work well for some small coins or air pods perhaps ? what was its purpose when you designed and made it. I seen some arm bands like this that held ipods several years back but they were aimed more at people working out i believe. ( the woman in the picture looks more like shes going to dinner than the gym) Maybe if you shed some light on the market you are targeting and your items use we could help with your question more. -

when i first started i wanted to hand dye everything. i soon realized i was better off buying my leather the color i wanted already dyed. plus you get better quality leather IMO. even the nicest hand dyed veg tan isnt as nice say a piece of buttero/dollaro or apollo mpg unless you do alot of hand finishing and even then i wasn't able to get the same type of result i was looking for. also ive had pretty good luck with fiebings water based and alcohol and angelus as well. i just use some Aussie conditioner (2 coats) after i buff the dyed leather and i haven't had any problems with the leather bleeding. if your concerned with the smell just dye your goods outside or by a window. i dont know what kind of goods you make but just some food for thought.

-

Do I need to use thinner thread?

CastleLeatherWorks replied to sonataworks's topic in Sewing Leather

I would say if you're having trouble pushing your thread and needles thru then your thread might be to thick. as i had the same problem when i first started. i bought ritza thread that was to thick and quickly realized i needed thinner thread. i also realized i dont like ritza thread much and now use waxed linen thread. Also its all personal preference for the look your going for. some people like heavier thread with bigger stitch spacing. i myself like short stitch length 3/3.38mm and .45mm thread as in my opinion it produces a cleaner higher end look, but i make wallets and smaller goods. if youre making holsters and saddles then you would probably use heavier duty thread. there is no exact recipe for this . so do what you like for the type of goods youre making. just my $.02 -

can you post a picture of an example ? what bag makers are you looking at ?

- 5 replies

-

- finishing edges

- finishing

-

(and 3 more)

Tagged with:

-

New Wallet

CastleLeatherWorks replied to CastleLeatherWorks's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

that might be exactly what im lacking as i have just been sanding my edges with a piece of sand paper folded and have noticed the "wavyness" lol. i appreciate your kind words and advice. as it was looking at your work that made me feel the need to step up my game when i first started a little over a year ago -

Where do they sell rubbery edge coat that factories use?

CastleLeatherWorks replied to magdy's topic in Suppliers

from my experience i believe many higher end bag makers use edge paint that is either sanded between several light layers or applied heavily and smoothed with a fileteuse. in the picture you posted it looks to me like the handle of a filteuse with a bent attachment. i dont think it is extruding anything as far as my eyes can see. i use the many light layers of edge paint (fenis or uniters) sanded in between coats on my wallets and it holds up very well. -

New Wallet

CastleLeatherWorks replied to CastleLeatherWorks's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

thank you i appreciate the nice words. my edges have definitely improved, still not as crisp as @Danne but im getting better lol take care -

I'm not a big fan of tooled leather but these are absolutely beautiful. i really like the ostrich and the boot shape ! ! Great Job ! !

-

Industrial Consew older machine

CastleLeatherWorks replied to robinsmarg's topic in Leather Sewing Machines

Have you tried google? or the consew website.... there's a whole list of machine parts diagrams on there. If that doesn't work maybe try calling them and they can probably point you in the right direction. http://www.consew.com/Resources/ -

would definitely be nice to see an actual image lol !! good job anyways...metalworking is fun ! !

- 11 replies

-

Watch Strap

CastleLeatherWorks replied to oakenlander's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

your work is awesome great job ! ! what size pricking irons or is that machine sewn? also is #92 thread for sewing machines? i only ask because the waxed linen thread i buy is 0.45mm thanks ! -

What can SLC do for you?

CastleLeatherWorks replied to TonySFLDLTHR's topic in Leatherwork Conversation

that's great to know. I don't know if you advertise that anywhere on your website but you should... I will def be ordering again in the future though. thanks ! ! -

What can SLC do for you?

CastleLeatherWorks replied to TonySFLDLTHR's topic in Leatherwork Conversation

i would like splitting services. as i do not own one myself..sometimes i like the leather you carry but don't buy because i cant get it split to the weight i want.