-

Posts

1,292 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by TomE

-

Might ask Springfield Leather. They do a lot of custom work and have a band splitter.

-

Spontaneous Combustion and Safety With Chemicals

TomE replied to Sheilajeanne's topic in Leatherwork Conversation

Saw a hay barn fire a few years ago while traveling along I-70 in Missouri. No one was on site and I think the fire was just starting. Next time I traveled that way the barn was gone. That's caused by microbial growth in the wet hay. My main hay supplier has a moisture tester on his baler that reads out % moisture content as the bales are produced. His hay doesn't sweat in the barn. Another reason round bales are popular is the whole process is mechanized and one person can produce and store the hay. It's getting hard to find kids who want to earn money bucking hay bales on a summer day. -

That's an odd diameter for a sanding sleeve. https://www.mcmaster.com/products/sanding-sleeves/ Perhaps you could switch to a standard size sanding drum on your arbor. I buy sleeves for my Cobra sander/burnisher from McMaster-Carr. They sell sanding drums as well.

-

Fun to try out different tools and learn new skills. That’s what it’s all about.

-

I just received a Gomph #12 and Osborne #10 overstitch wheels. Thinking about switching from pricking irons to these for bridlework. Faster and easier on the pocketbook.

-

I’ve been pleased with the Rocky Mountain European style pricking irons. I rarely use the 2-tooth iron and just tip and tap lightly. I assume you’re marking holes and sewing with an awl.

-

Received my spring punch from CSO today. Yes, they sent a new #0 punch tube with taller threads, and didn't do anything to the frame. I will sharpen the tube and be in business. It is a good size for Weaver's stamped bridle buckles.

-

Looks like a beast of a machine. Should be fun to work with.

-

That's beautiful and unique! Lots to take in regarding its construction and finish. The copper "peak" reminds me of my father who worked with copper and silver as a hobby. I use his polished hammer and few other tools in my leatherwork. Thanks for sharing.

-

Triple and double stitched halters

TomE replied to Mulesaw's topic in Saddle and Tack Accessory Items

Beautiful work, @Mulesaw! Your machine (and its operator) do a nice job sewing. Maybe you'll be supplying halters for the German sport horse market? Mary and our trainer are headed to Wisconsin this morning with 2 mares and their foals for a foal inspection. This is a "keuring" for the North American Dutch Warmblood (KWPN-NA) breed registry. These are jumper colts who will be weaned in a month or two. I think they're taking one bridle I made and everything else is ordinary purchased tack. It's like the cobbler's children going barefoot. -

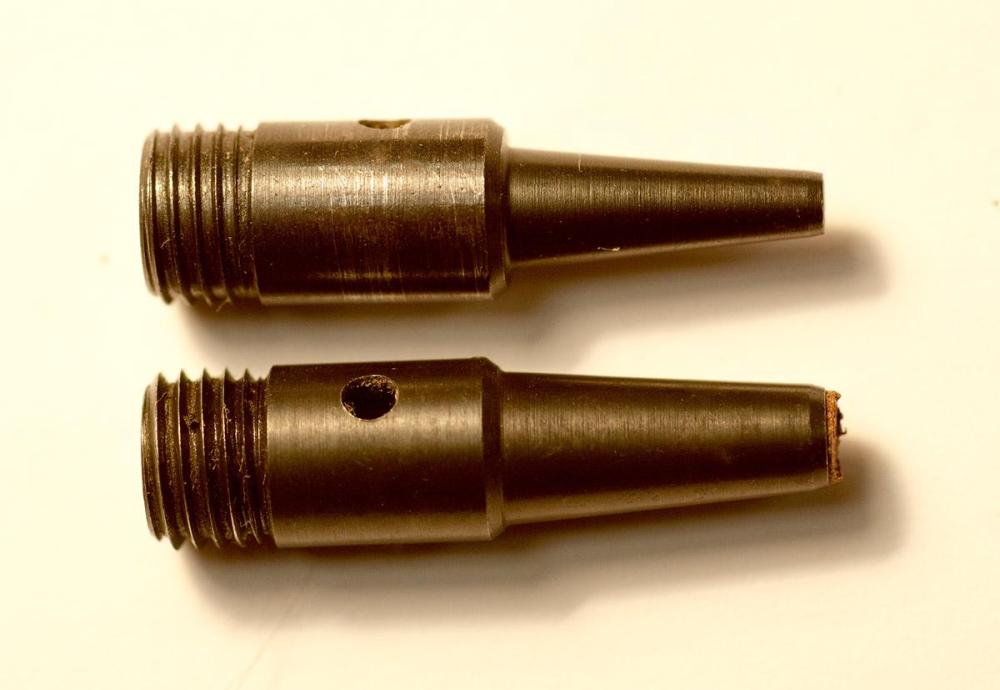

Thanks, Bruce. The tubes that screw easily into my frame appear to have the taller thread. In the picture below, the tube that fits is on the bottom and the tube that doesn't screw in is on the top. The frame was purchased about 4? years ago with a set of tubes that fit the frame. In 2022 I purchased a size #0 and #00 tube from Springfield Leather. The #00 fits my frame, and the #0 shown here does not fit. Perhaps the size #0 tube is the older style and everything else I have is the newer style? Here is a picture of the frame. The threads appear rough and flat, like they're not cut in fully. CSO didn't respond to my question about what size tap I should use to chase the threads. I sent them my frame and punch tubes as requested. I'll report back on what they return to me. I will try the steel wool polishing tip. Not sure if I can make an effective Q-tip small enough for the #0 and #00 tubes. Turns out that the #0 is my favorite size for stamped steel bridle buckles.

-

Do you recall when I was trying to rethread a hardened Osborne punch tube and you advised me about annealing, heat treating, and tempering? Worked great, except the inside of the tube developed scale(?) and tends to clog. I've tried polishing inside using a thread coated with compound but maybe haven't tried enough. Bruce Johnson recommended tapping out the punch frame to fix this mismatch of old and new Osborne punch tubes. This is a spring punch that holds a single tube. Finally got back to this project and called CSO to ask what size tap I should use. Their "technician" replied that I should just send in the frame and tubes. So I'm waiting to see what they come up with.

-

When you make a made-to-measure item based on the client's measurements then the client decides that the original item they took the measurements from wasn't a good fit after all.

-

I think the idea is to add enough baking soda to produce CO2 bubbles without neutralizing the acidic vinegar. So if you believe in scrubbing bubbles you can still get the benefits of the acid. Not my choice for metal parts.

-

Looking forward to it. Congratulations to Gustav! What an honor to be chosen by von Rönne. An experience of a lifetime.

-

Thank you kindly, @Mulesaw. Glad it was useful. I'm hoping to get more time for leathercraft in the coming months. The heat and humidity have kept us busy, changing our turnout routine and hosing off mares and foals that are hot. Cooler weather this week should make everyone happy.

-

Here I doubled up on 1" heavy elastic for these side reins. Abbey England sells this in a variety of widths including 2". For equine tack, the ends of the elastic are typically sandwiched between leather or nylon webbing chapes. These side reins attach to the bit and to the saddle and are used to maintain head position (with some give from the elastic) while working the horse from the ground.

-

The buckles of an English girth attach to the leather girth with a short piece of heavy elastic.

-

The best elastic that I've used for horse tack is sold by Abbey England. It is used on girth straps, side reins, and other items that see a lot of wear and tear.

-

Agree with @fredk. I would pre-punch the holes in the leather then sew with a harness needle to pierce the elastic without cutting the threads. The single needle backstitch that Fred refers to is a good choice for sewing woven fabric/webbing to leather. The overlapping stitches on the fabric side skip a hole and gather more threads in each stitch. This method is used to sew billets/girth straps to the webs of an English saddle to distribute the load on the webbing. This video shows backstitching for making a leather loop/keeper. The inside of the loop with overlapping, double length stitches would correspond to the elastic side of your project.

-

I'll put in a plug for PVA glue (Elmer's white glue). It is water soluble and doesn't interfere with burnishing edges of glued projects. It also allows realignment of pieces before the glue dries when needed. I use contact cement for most projects, but the white glue can be useful at times.

-

This thread may help.

-

@Uwe has produced some very informative videos that helped me understand and tame my 441 clone. This is my favorite for timing a TSC-441 type machine.

- 6 replies

-

- cowboy4500

- needle strike

-

(and 1 more)

Tagged with:

-

Welcome! I'm in Villa Ridge and travel regularly to Springfield Leather to pick out hides that were tanned in Saint Louis (Hermann Leather Co). We have some great local resources for crafters. Hope you enjoy this forum as much as I have and wishing you well. Look forward to seeing some of your sheaths.

-

Diamond hones with an elliptical profile work well on curved blades. They are sold by farrier supply houses for sharpening hoof knives. I've had good luck with the Mustad hone shown on this page, and the FPD (Farrier Products Distribution) brand is also typically good quality tools. https://www.farriersdepot.com/tools/knives/sharpener/