-

Posts

1,300 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by TomE

-

Thanks, @Mulesaw. I'm still experimenting with the creasing. I use heat to crease after beveling the edge and again after staining/drying and before sewing. The bridle leather doesn't hold a crease quite as well as regular veg tan. Stohlman recommends creasing cased leather (no heat) but I find the outside blade of my screw crease indents the beveled edge if the leather is cased. Thanks, @tsunkasapa. The reiny days only happen in my workshop. Today is a rainy day and I'm hoping the horse flies are about done for this year.

- 9 replies

-

- bridle leather

- equine tack

-

(and 1 more)

Tagged with:

-

Made some rubber reins using Equus grips from Abbey England and HO bridle leather. These grippy reins are used for jumping and cross country courses. Had fun sealing the edges with beeswax using an old Dixon edge iron from @PeterMain. Shout out to @jcuk for the tip about locating the fixed loop closer to the bar of the buckle.

- 9 replies

-

- bridle leather

- equine tack

-

(and 1 more)

Tagged with:

-

That's really interesting. I struggled with a new Vergez-Blanchard plough gauge that pinches the strap against the guide. There's a post about it in the Sharpening forum. I tried adding a very small bevel to the backside with no change in performance. I was advised to get a new knife (which I am on a waiting list for) and to get better at sharpening (which I have done.). The plough gauge works reasonably well now, but it still has a tendency to hang up because of the pinching especially for straps less than 1 inch wide. Maybe I should try adding a bevel to the back of the blade.

-

Lots of good advice in the comments. I'll add that as you use and sharpen your awls they will become narrower and suitable for fine work. I start using an awl for heavier projects and as it wears down with sharpening I put it on a smaller haft for the lighter projects with 9-10 stitches per inch. In addition to only sharpening the point, I like to shape the point of Osborne awls to a longer/more gradual taper. They are stubby when new. Your #17 harness needles are hefty. I am typically using #18-19 for sewing with #277 bonded nylon, and #19-20 needles for #207 thread. The Osborne harness needles have a smaller eye than the John James needles which suits me. I aim for the smallest needle that I can thread. If you wax the thread with beeswax and smooth it between your fingers before sewing then your grip on the needles will improve. I guess another way to avoid piercing the thread is to withdraw the thread from the backside as the needle is pushed through from the front.

-

You're correct that the knife blade should have a single bevel facing the guide and a flat backside. This setup pushes the leather strap against the guide. The knife might be repaired by taking the edge back to where the backside of the knife is flat and the front has a gradual taper of less than 20 deg. It depends on how much bevel has to be removed and how much blade is left. The tip of the blade should be positioned at or near the trailing side of the ruled bar that the strap slides across. If the plough gauge is an old Blanchard or Dixon in working condition, I think the frame alone is worth $200. They are hard to find and you could have a knife made for the frame.

-

Beautiful craftsmanship!

-

Thanks, @jcuk. So the sole purpose of this stitch is to gather the turn tightly around the buckle? I normally place the fixed loop 2-3 stitches away from the buckle end of the stitch line. Is it better to place it closer to the buckle as in your description? Always interested in refinements. @sbrownn, I've read that stitching across a strap may cause it to tear along the perforations. Perhaps more of an issue with horse tack than for a belt. The bridle cheek piece in the picture is a replacement for one that was torn by a naughty horse. Are you jumping from one edge to the other or continuously sewing across the width of the strap?

-

First leather belt

TomE replied to hickok55's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

It’s a look! Nice work.- 14 replies

-

- brass

- veg tanned leather

-

(and 2 more)

Tagged with:

-

Welcome. Hope you enjoy these forums as much as I do. The expertise shared here has put my crafting on solid footing. Can you post information about the shoe making class? Look forward to seeing your progress.

-

Look forward to seeing it. I haven’t made one.

-

-

Thanks to everyone for your comments and ideas. I'm reconsidering whether to routinely add a side stitch to buckle turns. It is more popular than I realized. I enjoyed reading your viewpoints.

-

The only thing I use a groover for is to seat a stud hook in the platform of a cheek piece. The groove made in the flesh side between the layers holds the base of the stud hook in place. I don't like the idea of removing the strongest part of the leather (the grain) for a stitch line. Kind of defeats the purpose of saddle stitching as a stronger method of sewing, which is another debate....

-

Yes, it’s a thing. I’m uncertain if it’s functional or just a look. My go to resources gave mixed results. Steinke (“Bridlework”) mentions that one or two side stitches are often added “to gather up” the buckle turn. Doesn’t give it a name or say whether it improves wear. This side stitch is inconsistently used by makers of expensive tack. Couldn’t find mention of this stitch by Stohlman in books on hand sewing, case making, and belts. As you said, I guess it’s my tack my rules. With bridles it’s usually the points or the buckle turn that tears out and the stitching isn’t damaged.

-

Does this side stitch on a buckle turn serve a purpose other than exposing the thread to wear and breakage? What is the stitch called? I added it to this replacement bridle cheek piece to match existing. On my own work I stitch straight up against the buckle and skip the side stitch. Am I missing something?

-

The narrow feed dog/throat plate from @RockyAussie has been a great option for my Cobra C4. It simplifies change up for heavy vs. light projects and I use it for everything. In-line presser feet from @CowboyBob (Toledo Industrial Sewing Machines) are a handy accessory for sewing raised leather.

-

Great to dream big. I dream of building a jumping saddle while honing my skills on bridles, reins, and halters. The more I learn about saddlery the less likely my dream becomes, but I'm becoming a better judge of saddle quality and fit. Feel privileged to learn this traditional craft and practice it at whatever level I can. @Key if you learn to hand sew there will be no shortage of projects that you can do.

-

Forget where I saw it but someone had sharpened a bicycle spoke to use as a fine awl for harness work. I'm thinking they were sewing 14 stitches per inch, which is out of my league.

-

A self-healing cutting mat from a fabric store is a handy item when squaring up the edge of a hide with a knife. A sharp round knife is ideal for making long, straight cuts but most any sharp knife will get the job done. For cutting straps you have a choice. The wooden strap cutter is inexpensive and effective, and the blades are more-or-less sharp out of the package (but even better if you sharpen them). A draw gauge is a handy tool for cutting medium width straps, but requires some practice and the blade must be sharpened before use. @bruce johnson has a helpful tutorial on holding the draw gauge at the Bruce Johnson Leather Tools website. The Cadillac (Rolls Royce?) of strap cutters is the plough gauge, especially for wide straps, but they are expensive and have a learning curve for sharpening and using the plough gauge. You will want to cut each strap along the full length of the hide, starting with the best leather along the back of the cow. You will notice the difference in substance at the butt (firm) versus the shoulder (spongey). The strongest/firmest straps come from the butt near the top of the cow.

-

Sewing with an awl is one of my favorite leathercrafting activities. You will need a stitching horse or pony, or saddlers clam to hold the work as you juggle the awl and 2 needles. Learning to sharpen an awl blade is essential to your happiness while sewing. No need to buy a fancy, sharp awl -- it will get dull and you'll need to sharpen it sooner or later. I mostly use Osborne #42 or #43 harness awls and shape the blade as I sharpen them. The points are too broad/blunt IMO so I put a more gradual taper on the point while sharpening the cutting edges. The awls eventually get narrower with repeated sharpening and those narrow awls are used for finer sewing. When I'm pushing through really thick leather (20+ oz) I use a peg awl haft with #44 or #45 awl. I think the ideal awl blade has a sharp point that pierces the leather, whereas the wider shank portion of the awl is relatively dull and stretches the hole as the awl is inserted. After making the stitch the leather relaxes and the hole closes around the thread. Highly recommend reading the Stohlman book on hand sewing leather, and videos from Armitage leather and JH Leather for sewing and awl sharpening methods.

-

Looks great. Hope the hip is doing well.

-

Very happy with the European style pricking irons from Rocky Mountain Leather. Using a sewing awl provides versatility in tidy sewing of odd shapes, very heavy leather (20+ oz), and complicated assemblies like sewing a fixed loop on a buckle turn. Stitching chisels generally create larger holes that don't match the thread size, which IMO defeats the purpose of hand sewing. I use awls of different sizes for fine (9-10 stitches per inch) and coarser (5-6 stitches per inch to match machine sewing) stitching. Highly recommend Stohlman's book on Hand Sewing Leather.

-

She's the real deal! Traditional saddlery skills applied to consumer goods. Beautiful craftsmanship and a sense of humor.

-

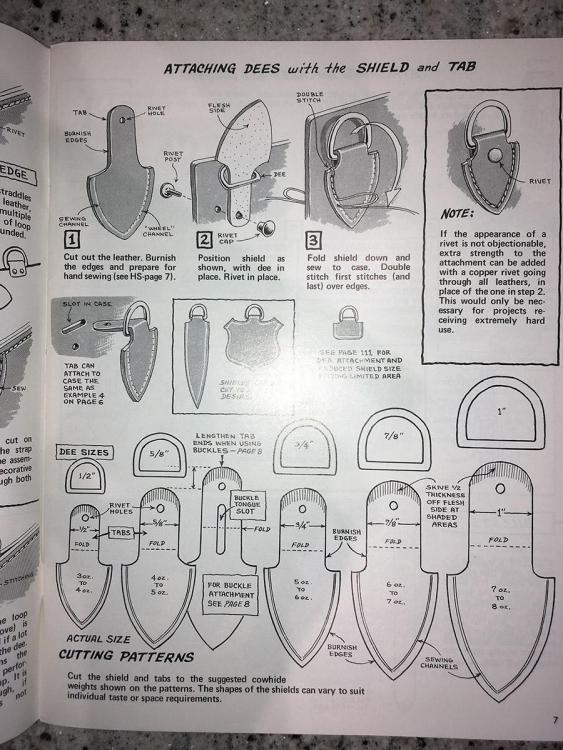

Another idea is to use a shield and tab to attach the double bar buckle to the bag. It would be even stronger if you sandwich the canvas between 2 leather shields and sew through all 3 layers. This illustration is from Stohlman's Making Leather Cases v. 1.

-

I built a frame with 6 legs made of 3" wooden fence posts and 2 x 4 runners, and covered with 3/4 inch sheet of plywood. You can stiffen it up by adding more crossmembers to the frame to support the top. I use the storage shelves underneath for --everything. I bought a cutting mat from Joann Fabrics and cover it with a flattened cardboard box when staining or gluing.