jrdunn

Members-

Posts

417 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by jrdunn

-

It just seems like thicker poster board to me. I think mine was called 6 ply.

-

@SUP, Since you live in a "cereal free zone", I might recommend "railroad board" poster board. I got mine from Amazon. Works good for patterns. JM2C, Jim

-

Now, that's a bunch of hooey. What really maters is your Zodiac sign. . .

-

How about fiberglass rods?

-

Just an update. My antivirus did not like it. I assume that it was just from an unverified host but wasn't willing to take the risk. (Been there, did that and got the T-shirt.)

-

I'm downloading it and going to see how far it is above my abilities. How much success have you had with it? Can you create laser ready files with it?

-

I think what @bruce johnson was saying is that you determine the correct angle for a given basket weave stamp. The idea (or ideal) is to set your angle up so the bottom corner of your stamp starts at your bottom border for each line of stamps. Bruce, feel free to correct me if I am mistaken. JM2C, Jim

-

Ubetcha!

-

Sorry I missed this. Good to hear from you again, Jonas. Sorry to hear about the illness. Hope all is well now. Pet damage is maddening sometimes. It seems like you have taken a "philosophical point of view". It has been my experience that it is much harder to train humans than animals. Jim

-

I'm gonna say that my CB4500 (which as far as I know, is the same machine) is about 40 inches wide and 26 inches deep. Hope this helps. Jim

-

Very funny. I'm no muzzle loader but I think they lube their bullets with it.

- 193 replies

-

- saddler recipe

- diy conditioner

- (and 4 more)

-

I have always heard rendered pork fat called lard. I do have some bear tallow mixed with bees wax that a friend gave me. He uses it shooting his muzzle loading rifle. He swears the stuff never turns. I don't know. I've had what he gave me for about a year. I've used it here and there. It hasn't went bad on me yet. JM2C

- 193 replies

-

- saddler recipe

- diy conditioner

- (and 4 more)

-

Like this one? Thanks to @bruce johnson https://brucejohnsonleather.com/leather-tools-sale/new-wayne-jueschke-mauls-string-cutters-and-riveters/

-

@Asavva, How is your friend liking the bag? I started thinking about making it and wondered if while carrying it the handle might open the bag? Loosen the drawstring. When I start considering a project, sometimes I overthink it. Thanks, Jim

-

That's nice looking! Where did you get it?

-

Does anyone like this type of belt buckle?

jrdunn replied to chingyoung's topic in Hardware and Accessories

I can't think of anyone. -

@SUP Here is what I bought from Amazon. I like it. https://www.amazon.com/dp/B071Y4CM3D/?coliid=I1QCOK7FF39BD1&colid=1AKLUS58CBF4H&psc=1&ref_=lv_ov_lig_dp_it

- 193 replies

-

- saddler recipe

- diy conditioner

- (and 4 more)

-

You guys are great! You start with a great looking bag and just keep enhancing it. I wasn't looking to make one of these but y'all are getting me in the mood.

-

Fredk's advice is sound. I also expect they'd also need to be thin and flexible, like the lining. I'm not sure that it wouldn't need to be fabric of some sort. Satin or synthetic of some sort, maybe? Sup, I did only claim that it was 2 cents worth.

-

Yeah, and maybe a inside pocket or two. My wife loves pockets. I don't know why. She spends most of the time looking for something lost in the main body??? As usual, JM2C. Jim

-

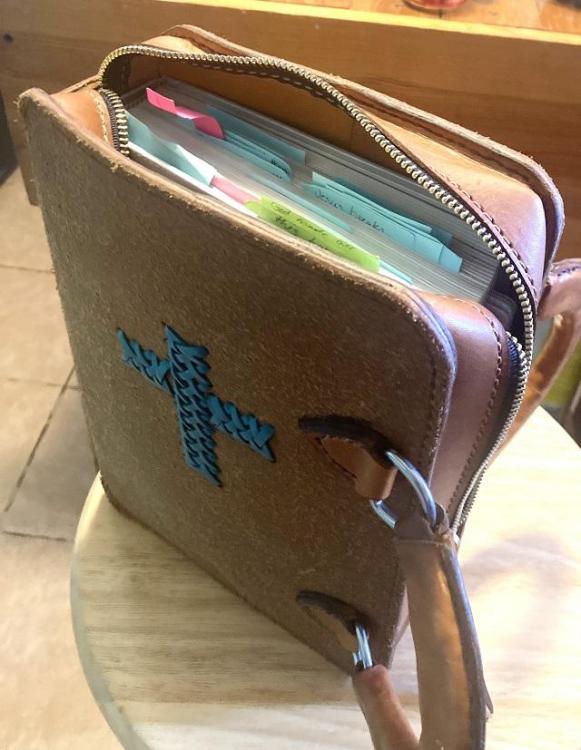

@Dwight, Thanks for posting Aaron's video. I watched it and learned a lot. How are you planning on implementing his method of zipper installation into your Bible cover? I assume that it has a wrap around zipper in a gusset. I only ask because I would like a less nerve racking and less dreaded method of zippered gusset installation. I have completed reasonably good looking covers with Al Stohlman's method but cannot say that I'm proficient or even comfortable with it. If I could get at least semi-comfortable with that, I think I would enjoy making covers. I included a pic of my first zippered cover.

-

New (to me) Randall! lots of questions...

jrdunn replied to maggielj's topic in Leather Sewing Machines

Very cool! -

Sorry, I quoted the wrong post. - - Leather Cases, Vol 2 has great info on making YOUR OWN pattern - very helpful. Or, Amazon has a bazzillion Bible covers for not much money. As for whether to zipper or not, YES! A CLOSED case is mandatory if your Bible is dropped, or hit, or slides off a car seat. So, YES! @Dwight. +1 on the Al Stohlman Leather Cases Vol. 2. I've made three with a zipper and hope I don't ever make another. Me and gussets + zippers are not friends. I myself carry an "off the shelf" one. I've made one for the granddaughter, my wife and daughter-in-law. I don't like myself as much as I like them. I should probably talk to a therapist about that. As usual, JM2C. Jim PS. I made one for my youngest granddaughter that was more of a "sleeve" with handles. Lots easier.

-

My therapist says "Just because you're paranoid doesn't mean that everyone isn't out to get you."