-

Posts

7,808 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Wizcrafts

-

Are you saying that Beiler's flat plate retains the use of the moving feed dog? I thought you were telling me about an alternate narrow slotted throat plate that would sit above the top of the feed dog as it moves up and down. My holster plate already does that. I can leave the feed dog in when I install the raised holster plate. Could you post a picture of this new style flat plate? I Grok things better visually. Before I got my Cowboy CB4500, I used Union Lockstitch machines for holster and harness sewing. They are dual feed with jump foot and needle feed. This was a better system in my opinion, until you get into thinner needles.

- 28 replies

-

- cowboy4500

- stitch loop

-

(and 1 more)

Tagged with:

-

Bob has always had a flat slotted throat plate since he started carrying the Cowboy machines. I have one in my shop. The only difference is that the Cowboy slotted plate requires removal of the feed dog. It is very thin, just like the standard curved plate. This takes me about 5 minutes. I will contact the Amish Country dealer about his plate. Thanks Glenn.

- 28 replies

-

- cowboy4500

- stitch loop

-

(and 1 more)

Tagged with:

-

Okay, I Grok you now. Sewing thin material on a 441 clone requires you to dumb down the machine (read my blog article). This involves lessening all tensions and pressures. It also calls for some thin needles that are really easily deflected. In a nutshell, you need to spend 20 minutes or so changing settings and tensions in order to be able to sew 6 ounces or less with 92 thread with a #19 needle. I do this when I hem chaps, jeans and work pants on my CB4500 (because I don't currently own a medium duty cylinder arm walking foot machine).

-

I can't find this company in a Google search. Would you know if they have a website, or are on social media? A link would help.

- 28 replies

-

- cowboy4500

- stitch loop

-

(and 1 more)

Tagged with:

-

Sewing Machine Recommendation for Small Leather Goods?

Wizcrafts replied to YSRASupply's topic in Leather Sewing Machines

Really? I serviced a few model 27, 28, 127 and 128 machines and they never had that problem afterwards. The biggest problem I encountered was securing the bobbin thread to wind a bobbin! The last Singer model 127 I refurbished and sold could sew with #92 bonded nylon thread into a 10-12 ounce bridle leather strap. None, and I mean NONE of the other old iron body Singer domestics could even come close to that. That includes classes 15 and 66. -

Both of these machines are known as 441 clones and are equally caapable. They are clones of the Juki TSC-441, from around 1988 or '89, which was marketed to companies sewing buffing wheels, heavy webbing tow straps and leather harness. The 441 had a huge double toe presser foot, a wide inside foot and a wide feed dog, all of which had teeth to grip the material. The machine used needle sizes 23 to 27, covering thread sizes 138 through 415. Most users threaded it with #346 thread. It was never expected to be used to sew thin material with small needles and thin thread. For that they made the LU-563, which I had. The Cobra and Cowboy 441 clones have a different type of foot design that is geared towards saddlers. It is known as the "harness foot set." The outside presser foot is about 3/8 inch across and the inside foot is just under 3/16" wide. Because the machine was cloned from a TSC-441, the feed dog is still very wide and has a wide, long hole for the needle. This extreme needle hole is needed because the feed tolerances allow quite a bit of range off-center as the feed dog moves forward and backward at different stitch lengths. Aerospace tolerances would solve that problem and allow for a more rounded hole, but that isn't the current state of affairs. Further, because the 441 clones are expected to be used with thick threads, up to #415, they have to allow for needles from #23/160 (for #138 thread) up to a #27/230 (for #415 thread), which is about the diameter of a roofing nail. So, you have a long and wide hole/slot inside a very wide feed dog that rides inside an even longer and wider rectangular slot in the throat plate. Thin and/or narrow straps are easily pushed down into the throat plate slot and sometimes the feed dog hole. Backing off the foot pressure reduces the tendency to push the material into the slots, but is just a stop gap measure. My solution is to remove the feed dog and change to the optional slotted throat plate and back off the presser on the feet to lessen the drag on the throat plate and foot impressions on the top grain. This takes about 10 minutes to change over. Better still would be to use a smaller machine to sew anything under 8 ounces, with thin thread and small needles. I have a bunch of such machines in my shop. Your Cobra and Cowboy dealers sell a slotted throat plate, which is already included in the deluxe accessories package. If you are going to sew as part of your business model, plan on buying more than one type of sewing machine. There isn't one that is equally adept at sewing from a few ounces up to 3/4 inch or more.

-

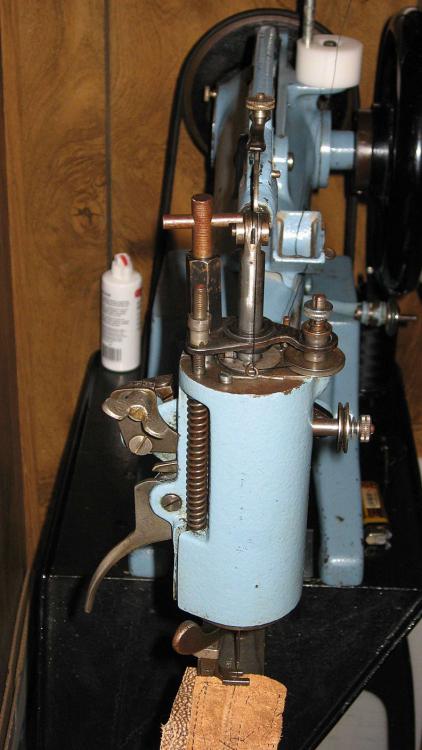

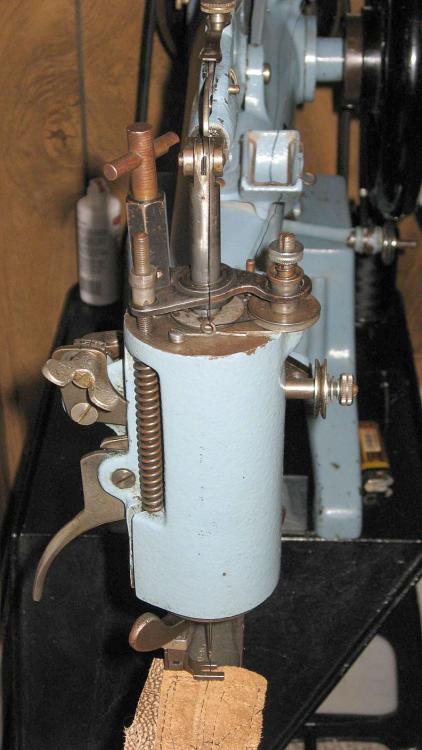

Singer 111W153 & table resto project

Wizcrafts replied to Sugarkryptonite's topic in Leather Sewing Machines

I believe it is a presser foot knee lift roller, but I could have misread the description. -

Sewing Machine Recommendation for Small Leather Goods?

Wizcrafts replied to YSRASupply's topic in Leather Sewing Machines

We discuss industrial leather sewing machines here. Your question might get a better response on a forum that deals with plastic body domestic machines. I'm sure somebody has tried sewing leather on such a machine and can advise you of how that went for them. My own experience with plastic body electronic domestic machines sewing 5 or 6 ounces of leather was parts flying across the room. Now, if you were asking me about an old iron body Singer model 27 or 127, that's another story. -

Singer 111W153 & table resto project

Wizcrafts replied to Sugarkryptonite's topic in Leather Sewing Machines

That is one beautiful piece of work! Kudos! -

It is spring loaded and free turning. You just turn it to the desired position before it is hit by the needle bar. It can be mastered in about 5 standard Earth minutes.

-

I have a Fortuna skiver (date unknown) and a newer Singer 29k71 patcher. I have owned numerous patchers, all the way back to the 29-4 model from the turn of the 20th Century. Here is what I've found about your 51-28 (last one made in 1938), which says the recommended replacement was the 51-54, having these specs: Post bed; one-needle; rotary hook; lockstitch. Speed 3000 spm For general stitching in the manufacture of shoes; vamping; sewing in gores, etc. Needle system 128x4. There was a recent discussion about the Singer 51-54 needle system on this page on Leatherworker.net. You can search our site for any other discussions mentioning the 51-28 or 51-54, using our own search engine, on the upper right, under the ad banners.

-

-

Yes, I have darning attachments on my Singer 29k71 and Adler 30-7. I use them once in a while to get longer stitches, or to darn across tears in material. These attachments have three positions: off, medium lift and high lift. You just rotate the T shaped handle so it either hits or misses the rising needle bar.

-

Sew I bought an older Singer 211G155

Wizcrafts replied to millrat's topic in Leather Sewing Machines

We have supporting industrial sewing machine dealers who advertise with us via ad banners on top of every page. I know at least two who stock Singer industrial sewing machine parts and aftermarket replacement (Chinese) parts. But they are not close to you. If you end up having to replace worn parts, like the hook, by yourself, watch some YouTube videos first. Almost every aspect of timing and rebuilding Singer sewing machines has been covered by somebody, somewhere. Download a parts list if possible. -

Then seek out an Adler 30-7 or 30-70, or a Singer 29k72, or 29k172 on a power stand. These are all long arm, large bobbin patchers. The Adlers can both clear and sew up to 3/8, while the Singer maxes out at 5/16 inch. A motorized machine lets you keep one hand on the work and the other on the butterfly knobs on the direction control ring. I had a Singer 29k172 I'd sell ya but it is gone now.

-

I have sewn with patchers from Singer and Adler for decades. I currently own a Singer 29k71 and an Adler 30-7. I keep #69 bonded nylon thread in the Singer, because it has a super tiny bobbin. The Adler has a larger bobbin and stronger take-up parts so I use #92 and #138 thread in it, as the job demands. I only use these machines when a flat bed walking foot machine can't do the job. Flat beds are best for flat work seams. The patchers are used to sew patches over pockets, or onto sleeves, or to sew small round things (think koozies), or long circular items (think cue stick or rifle bag), or inside purses and other bags. They are specialized machines because of their universal top feed. It is difficult to maintain a straight stitch line on a patcher since there is no easy way to install an edge guide. Also, the teeth will leave serious marks in veg-tan leather. You can definitely sew straps and flaps and zippers onto tote bags with a patcher. Just staple, pin, or tape the straps in place before you sew. But, get a flat bed walking foot machine, with an edge guide, for the basic flat seam and piping construction. Many have oversize bobbins that hold lots of thread, up to #138.

-

This servo has a cork brake attached to the speed lever. When you just push down on the lever the brake disengages. You are probably hearing the squeak of the brake against the clutch plate in the motor. The cork brake is screwed on and is removable, or can be sanded down, or greased to cure the noise. If the squeak persists after the motor is spinning, this could be a bearing noise. Contact the seller.

-

Singer 111W153 & table resto project

Wizcrafts replied to Sugarkryptonite's topic in Leather Sewing Machines

There is an animated gif on Toledo Industrial Sewing Machines' website, on the Videos page, showing how a lockstitch is formed. It may help clear up some confusion among newbies to lockstitch machines. -

Sewing Machine Recommendation for Small Leather Goods?

Wizcrafts replied to YSRASupply's topic in Leather Sewing Machines

According to this thread and needle chart, 0.6mm is the slightly bigger than #277 (T270) and slightly thinner than #346 bonded nylon thread. Let's call it imaginary T300. You will need a holster/harness stitcher that can use #25 and #26 needles to sew that thickness of thread. The hook and shuttle will be around 2.5" or more in diameter. The least machine I know of that can handle this thread and needle combination is the ancient Singer 132k6 (a buffing wheel stitcher). The next step up is the GA5 type machines (e.g., CB2500 and the Techsew 3650HD), then 441 clones like the CB3200, the Cobra Class 3,). That takes care of the machine problem. But wait: these are lockstitch machines. When they form a stitch the top and bottom threads overlap inside the material. the thicker the thread, the larger the "knots" formed by the overlap. In the case of #277 thread (0.586mm) the knots are about 1.5x the thread diameter. It will take approximately 3/16 inch of leather to completely hide the knots with #277 thread. If you were to use #138 in the bobbin, you'd still need at least 1/8 inch of leather to bury the knots. -

Sewing Machine Recommendation for Small Leather Goods?

Wizcrafts replied to YSRASupply's topic in Leather Sewing Machines

I would sew these wallets on a flat bed walking foot machine. They don't require any thread larger than #92, or maybe #138 bonded nylon. -

Sewing Machine Recommendation for Small Leather Goods?

Wizcrafts replied to YSRASupply's topic in Leather Sewing Machines

The Cobra Class 4 can sew with up to #415 thread. #207 is towards its lower end. The Juki that sews with up to #207 is the LU-1508NH -

The check spring's job is to keep the thread taut until the needle enters the work. Is it stops moving down too soon the thread will be loose at the tip of the needle, where it can get pierced. the only caveat is that it must stop moving down before the needle starts ascending to form a loop for the hook to pick off. Otherwise, no loop for you!

- 28 replies

-

- cowboy4500

- stitch loop

-

(and 1 more)

Tagged with:

-

Can anyone identify this tiny mystery part of a Pfaff 545

Wizcrafts replied to MaryLee's topic in Leather Sewing Machines

The little stud is the tension release stud. It goes inside the hollow threaded post upon which the tension parts reside. -

Pfaff 545 industrial sewing machine overview and video

Wizcrafts replied to gavingear's topic in Leather Sewing Machines

That is the tension release rod. Feed it inside the hollow threaded post that holds the tension disks and release plate, spring and thumbscrew. If that little stud is perfectly straight, it can go in from the back before you reinstall the tension release bracket. If it has a bigger end on one side, or if the release bracket is already screwed down, feed it in from the front through the hollowed post. Then install the two disks, the metal plate that the little sud pushes against, the beehive spring and the nut. Some things are better left alone, if you know what I mean.