-

Posts

7,378 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by JLSleather

-

some more holsters

JLSleather replied to chuck123wapati's topic in Gun Holsters, Rifle Slings and Knife Sheathes

-

Bifold Wallet

JLSleather replied to lansacoder's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

-

1 of 2 ways, generally . Use kidskin - from S-T Leather. Very nice, very consistent feel and colors. About 1.5 oz. Double check, but I think it's item L3777 in their store. Skins are about 5 sq ft, give or take a bit. Very nice. It's chrome tanned, so the edges don't burnish. I either skive a taper or fold the edge over on outside edges (not pocket tops). Their web site is WEIRD at the moment, just call them at (314) 241-6009 Alternatively, consider the Chaylor-Finelli inserts distributed by Springfield Leather. I have used a number of various styles and found them all to be quite nice. Customers always like them. Very easy to work with. Being pre-made, you would want to be sure that the size is correct for your project before beginning. Being part leather and part fabric (innards) these are even thinner - still very nice.

-

A Little Weekend Project

JLSleather replied to AzShooter's topic in Gun Holsters, Rifle Slings and Knife Sheathes

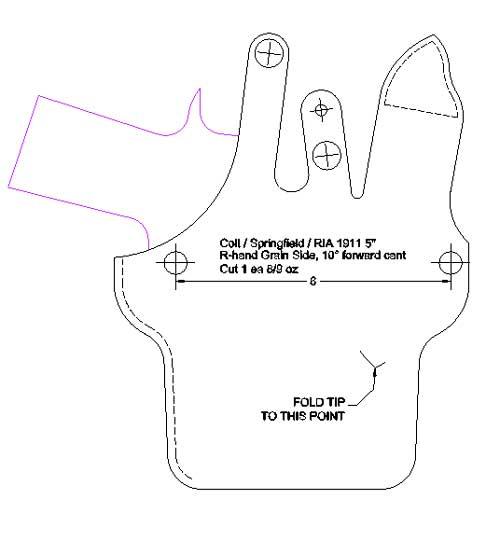

Oh, yah - it should be obvious, but just in case .... The pattern shows actual size for the main body of the holster (you could trim it if you don't want room for the initials) but not for the 'clip strip". This is because .... depends on the clip you use. Just trace or sketch your clip, then cut the leather 1/4" wider on all sides. -

Yup... staying at it like i dun figgered ya wuzz Here's one from .. last year (?) ... that was kinda the same thing, though I filled in the letter. Tried to tone it down a bit by making it 2-tone with some of the purple ... that "hot pink" was BOLD! But looking at the gun you see WHY the purple. Sent her to a color picker online, had her send me the RGBs for the color she wanted. Miss Katherine likes it

-

A Little Weekend Project

JLSleather replied to AzShooter's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Oh, yah - you DID say 2 years of posts, not 2 hours of snoop. Correct. Guess i didn't pay much attention to you Nor should you be. I have a history of noticing what others don't, and have on occasion been known to say what others won't. -

A Little Weekend Project

JLSleather replied to AzShooter's topic in Gun Holsters, Rifle Slings and Knife Sheathes

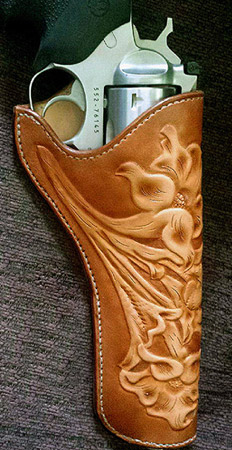

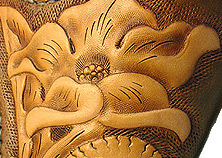

You really should get some kind of a life. I can't imagine any SANE cause for digging through somebody else's stuff, especially not for hours ... I wouldnt' even do that if they ASKED me to. I don't think I was making this style holster around 2010 - most of the holsters I do are TOOLED leather. In fact, had you asked a simple question I could have TOLD you that and saved you all that time. Course, you woulda missed out on seeing my cool stuff. I was doing stuff more like this ... and these ..... since these do at least take SOME skill / experience to make. But certainly NOT this, since as anybody who knows me or any of my work knows I would never leave this ... space .... on any holster I make. You know, cuz ... "IF what you do is something that ANYBODY can do, then don't be surprised when ANYBODY does.", and those 'cut it out, sew it, and form it" holsters definitely something anybody can do. In fact, SO MANY people started popping up with FOR SALE patterns around that time that I made some myself TO REMIND PEOPLE just how simple this is, and that a guy really don't need somebody else to do the layout for 'em. The person in that video appears to be one big fat wrinkle (sad when even a guy's WRISTS have folds) ... and even he/she seems to be doing okay, thus we conclude ANYBODY can do it. Incidentally, I made these SPECIFIC holsters with tooling designs from WAY back .. 1) because I personally like them, and 2) because SO MANY people were suddenly "tooling" leather (probably too gracious for some of what I saw) and I wanted people to be able to COMPARE what others tooled with what I tooled, WITH THE SAME PATTERN. But, lemme git on back to patterns n holsters n stuff. Now in 2021, I find I'm quite bored with those "plain" holsters. Again. SO bored in fact, that I'm currently only making them for people I know, and only by specific request. I plan on making more holster PATTERNS, though, and I'll need to MAKE them to test the fit, so there's that to do. MEANWHILE, seems a bit rude to talk this much about patterns and NOT provide AT LEAST ONE. That in mind ... what do I have "laying around" that some folks could maybe benefit from? Oh, hey - how about this simple little clip-on IWB for the SW Bodyguard! EVERYBODY use this pattern, make a holster, take a pic of it and upload it to here. We could have an "anybody can do it" photo gallery ... and the winner gets.... NOTHING at all (but the pattern is FREE). Yes, that's a small bit of sueded leather on the inside face, for TRACTION I'll git the pattern 'processed" here directly, but for now i'll say this took a piece o' 7/8 cow about 8" x 4.5", another strip for the clip "retainer" piece, a clip of your choice (I'll include the SIZE of the clip used, but don't remember WHICH one exactly) and a rivet. Dye and finish as you see fit... and attach small piece of suede leather (or cloth, or cork, whatever). Wait.. no point to "process" something this simple. Just remember to mark the sewing line ON ONE SIDE ONLY... the other side is shown just so you can easily mark the GLUE LINES on the inside. The clip used is shown full size... alter or use another style if you want it to ride higher or lower ... BG380_C3.pdf Actually, ya know what? Fer you OWB folk, here's a mag carrier for that same little shooter ... SAME COST Mag_SWbg_P0.pdf -

A Little Weekend Project

JLSleather replied to AzShooter's topic in Gun Holsters, Rifle Slings and Knife Sheathes

this must be same pattern, I guess? I'll have ta snoop around, see if i still have this tooling design anywares near here ... -

perhaps. or perhaps they're making more of them because they're cheap and easy to make and they sell? where's the british gal usedta come around here.... beautiful stitching at like 11 to the inch... can't remember what her name was now ...

-

I don't like "chisels". I didn't like them in the 80's when they were well made, and I certainly don't like the 'stuff' tha's available now. A good awl is much better for getting all the holes consistent depth (size) for the thread, works on items that arent' flat. Having said that, a GOOD awl is tough to find too. yeah, that's what I said. Turn off the videos and all that time-sucking noise, and PRACTICE.

-

What weight is that? PM me an address and I'll send you a piece of what its' SUPPOSED TO look like... pretty sure i have some 3/4 oz and some 4/5... not sure i have any 2/3 left around here.

-

A Little Weekend Project

JLSleather replied to AzShooter's topic in Gun Holsters, Rifle Slings and Knife Sheathes

our pattern fits the .22? Good to know Still, who's this Ables fella? That holster looks familiar ... Maybe we'll gitya to try out this other thing.. see if this fits ya as well ... Right hand, very simple thumb break holster with integral belt loop Able might have one JUST like it ... -

Yup, looks nice, I think you're right 'Assa good point

-

-

Not a chance I'm spending half an hour watching some dufus go on about something as simple as sewing with a needle SERIOUSLY folks... you want to know how to work with leather? You have to WORK WITH LEATHER. Stop spending your day on y-tube (pronounced WHY tube) and ACTUALLY DO IT. Grasp the idea that you're going to make some mistakes, and jump in. I love AL's books - probably owned most of them over the years. But in this one, even Al (who is usually very to the point and informational) got a bit WORDY. The book ABSOLUTELY IS worth having if you can get it.. just keep in mind that the principle is very simple.

-

What are the shaded parts on the first one? And... I don't mind the LOOK of that last one, though I suspect it could get irritating catching on belt loops when put on.

-

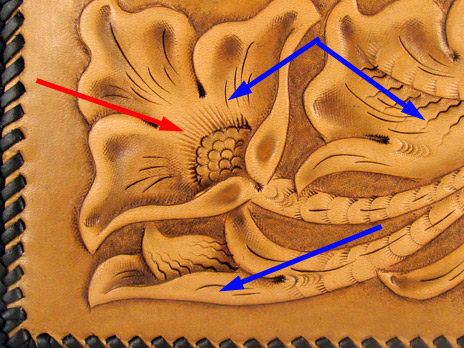

Your principle lines should be CUT WITH A KNIFE, 1/2 to 2/3 through the leather in most cases. Having done that, the "straight up and down" side of your beveler goes ON the line. Bevel to the outside, AWAY from the flower if that's what you're tooling. As for shading, DONT think of distance from the cut lines... instead try to visualize where the petals (since you specifically mention those) would be "low" or "high". There are A BAJILLION videos showing "leather tooling", and I'm gonna say most of them are CRAP. Don does a pretty good job of telling you what he's doing and why ... this video is part 2 of a series, specifically shows using a beveling tool. https://www.youtube.com/watch?v=tkKCtA5al00

-

These terms have been polluted and convoluted to the point where they mean virtually nothing. "full" grain once meant the entire skin, as opposed to "top" grain, which seemed to denote a leveled hide - leveled by removing the BOTTOM section to end up with a consistent "top" piece (the underside was often modified to become suede leathers or "prints"). Hermann Oak Leathers (St Louis, MO) sells tooling leather "split" to the thickness you need. The hair has been removed and the hide has been "tanned" (another term that has been through the wringer over the years). EVERYBODY will rush to tell you that H.O. is THE best leather. Just keep in mind that they sell GRADES of leather, and not all are equal in condition or cost. That said, I DO recommend HO tooling leathers, but would add that if you're buying through a retailer you're going to pay a SIGNIFICANT markup, and if you're buying "panels" (or other small cuts) the markup will likely be WORSE. While we would all LIKE TO BELIEVE and EXPECT to pay more for a "panel" or "piece" with defects removed (cut away)... that is NOT guaranteed. There are those who will gladly cut a piece of "C" grade leather, complete with visible defects and "mushy" spots, and sell it to you at a PREMIUM price. Buyer beware ...

-

the curve (radius) of the tangential arcs are bilateral, and such that the pivotal center of the arc is maintained in a position inversely proportional to the square of the strap width. Even more so on Tuesdays before dawn. Seriously, this is not something you need vector software for.

-

Based on WHAT? What is the "right" proportion of cut length to strap width? What is the "proper" radius of the curve of the cut? How does leather thickness affect the proportion? If you "worked out" a pattern, that seems to suggest that you have A way, not necessarily THE way. This is perfectly acceptable, but it does reinforce the idea that there is no "right" way to shape a belt tip... Oh, I guess I assumed it was clear, but maybe I should have said that this heavy paper (card stock) becomes your TEMPLATE ...

-

There is no "right" way. Cut it the way you like it. Easy way to get there is cut a piece of heavy paper the width of your strap, and the length of a sheet of paper or so. FOLD the paper in half lengthwise (so you have a piece 11" x HALF THE WIDTH you started with). Using a knife or shears, cut a curve you think is "about right" through BOTH layers. Open the fold, and the two sides will match. Don't like the look? Fold it back together and try a different curve, until you get what you're wanting. Once done, measure from the tip to where you want your holes, and mark (or punch) the holes on the folded line.

-

Mag holster for myself

JLSleather replied to lansacoder's topic in Gun Holsters, Rifle Slings and Knife Sheathes

tough to see much detail in that pic, but I rather like the overall look of it. might ride a tad higher than I like, but each his own -

What kind of Hammer for stichlines and gluing?

JLSleather replied to Silvyr's topic in Leatherwork Conversation

doesn't matter... as long as the face is smooth. in fact, you could "hammer" your stitching with the back end of a punch for that matter ...