-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Adler 30-10 Upper Tension Issue

Constabulary replied to Sunny9072's topic in Leather Sewing Machines

can´t tell from the Video whats wrong. So from what I n´see it is working normal - I would check if someone probably put a disc between the tenison spring and the small cup the spring sits in (who knows). I´d also try a different thread - the thread looks like old heavy duty probably pre-waxed cotton thread. Try #96 polyester thread. When you have new thread check the bottom tension - seems to be too low (probably). Can you post a picture how the thread runs through the oil cup. -

Adler 30-10 Upper Tension Issue

Constabulary replied to Sunny9072's topic in Leather Sewing Machines

please post pictures of your machine and the thread path. Or can you post a short youtube video? What the thread thickness you are using? W/o sitting in front of your machine the 1st think I would try is shorten the top tension spring. Then - usually there is a thin felt or leather disc under the top tension discs - it should be approx 1mm tick - if thicker it could increases the tension. If your machine has a thread guide instead of a oil cup (later Class 30 models often do no have an oil cup) let the thread just run through 1 or 2 holes. -

Consew 226 Stitch Selector Not Working

Constabulary replied to Kryptonite's topic in Leather Sewing Machines

most vintage sewing machines have an un-precise stitch length adjustment. Most lot of them don´t even have the stitch length marked on their dials - if they have a dial at all. -

Maybe not too importation for you but the 20U is using the same needle plates and feed dogs as the Singer 107W & 457. So you have quite a wide range you can choose from. How do I know? Well I once ordered a 20U & 457 needle plate and feed dog for my 307G2 AND the needle plates of my 107W1 fit the 307G2 as well - conclusion - 20U and 107w / 457 needle plates and feed dogs are interchangeable CS in the UK has a wide range but I´m sure you can find them in the US as well. https://www.college-sewing.co.uk/store/Singer107G,107WSewingMachineParts https://www.college-sewing.co.uk/store/Singer457G,457USewingMachineParts

-

Grease for Gears in Gearboxes

Constabulary replied to Scoutmom103's topic in Leather Sewing Machines

usually most gear boxes are not completely sealed and would not hold the oil. Most also do not have a filler and drain screw.- 28 replies

-

- grease

- industrial sewing machine

-

(and 1 more)

Tagged with:

-

Grease for Gears in Gearboxes

Constabulary replied to Scoutmom103's topic in Leather Sewing Machines

The problem with greased gear boxes is that even when you put a good amount of grease in them the lubrication is not better as when you just grease the gears (and not the surrounding) Why? Because the grease that got "squeezed out" when the gears get in contact with each other does not "fall back onto them because of the consistency of the grease. I noticed this on several old sewing machines when I opened the gear boxes and cleaned out the old grease. Hope you know what I mean. I even tried a very soft grease too but result was always the same - the grease does not fall back onto the gears. Question is does it make sense to grease the gear boxes at all? Sure they need a lubrication but not necessarily grease. So what I do is I use clear synthetic chain lube for motor cycle chains which is quite sticky. This also reduces the gear sound (you sometimes have that on certain machines). I´m also using this stuff on the cams of my patcher machine. Not saying this is the best you can do but this just what I do - others may have other or better ideas. Often people make too much "science" out of oil and grease topic. Even Lilly White will keep your gears well running, I bet. So I will not jump into a "greasy" discussion - I just say what works well for me. BTW - Once I even found a note in a Singer manual that the lower gear box should not necessarily be re-greased because it got oiled by it self with excess oil dripping down from the mechanics. But I have to look into the manual again for the correct wording...- 28 replies

-

- grease

- industrial sewing machine

-

(and 1 more)

Tagged with:

-

Changing out a handwheel with a motor pulley

Constabulary replied to leecopp's topic in Leather Sewing Machines

I have seen several well working modifications like this here on the forum. Personally I prefer the OEM hand wheel + under table speed reducer solution for a simple and probably dumb reason. I don´t like the appearance very much - I don´t say one or the other way is the better solution I just like to have hand wheel as it came with the machine. Different strokes for different folks -

Crackle Coating Singer 111G156, 107W1...

Constabulary replied to Constabulary's topic in Leather Sewing Machines

as always - the truth is somewhere in between. Only the wise Isaac Merritt Singer and his descendants know -

Crackle Coating Singer 111G156, 107W1...

Constabulary replied to Constabulary's topic in Leather Sewing Machines

This is what singersewinginfo.co.uk says - http://www.singersewinginfo.co.uk/blackside/ -

Crackle Coating Singer 111G156, 107W1...

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Thats right - thats what the IR heater in the background is for. I apply heat immediately I don´t let the paint dry by it self. That really helps a lot - you can almost watch the paint starting to wrinkle. All sports wrinkled but the thinner the coat the finer the wrinkle is. Spots where I applied "too much paint" have a MUCH more uneven (rougher surface -anyway - still good for me. -

Couple of weeks ago LW member Parfektionisto painted his 45K with VHT crackle paint (looks amazing). Later on I got my 108W20 and I have touched up the paint job with VHT crackle paint (or Wrinkle). So - yesterday it was time for a full repainting of the 111G156 head I got last year when I picked up my 132K6 (which still is not setup ). Turned out quite nice yet not perfect but good enough for me. Flat bed I painted gloss black a few weeks ago. Next will be the 107w1 (was a lemon when I got it) I just recently acquired...

-

Post some pictures of the machine and a picture of the name plate / data plate if possible.

-

Sometimes you can find the Pfaff 138 with a wider 6mm ZZ but they are harder to find.

-

some sew fast - some sew slow - some sell items - some don`t. Some have big ones - some have smaller ones... Machines I mean... or Pizzas Amen 2.0

-

Amen!

-

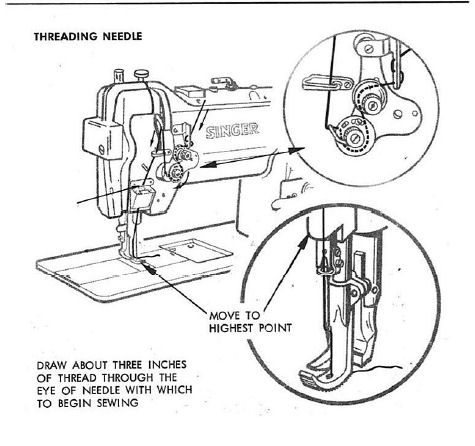

just to add something "official" Pic comes from a Singer 211 operators guide - tension unit is the same.

- 22 replies

-

- 111w155

- threading the tension disks

-

(and 1 more)

Tagged with:

-

Not sure of this particular subclass but a Singer 211 manual should work. I have attached a few 211 files I have - hope they help Service Manual Singer 221G155_211G156.pdf Singer 211 Operators Guide-Small.pdf Parts List Singer 211G165_166_265_266.pdf

-

Guess you need a speed reducer then

-

$1850 and no support from the Co. you bought from ? The machine came w/o manual? Wondering who the seller was. Please post some machine pictures and the model number or name. Cobra 4 / Cowboy 4500 have been discussed dozens of times here click: Cobra 4 click: Cowboy 4500 but I´m sure some users of either machine will jump in here soon.

-

Adler 167 - Timing Belt Replacement

Constabulary replied to Constabulary's topic in Leather Sewing Machines

You are welcome - hope you were able to squeeze the belt through the small gap. For me it was like a PITA -

Unfortunately I have no safe information but I have a presser foot with # 48218 that works with my machine. I think it once came from an Adler 48 machine - the Adler 48 is pretty much the same as the Singer 17 and Pfaff 23, 25, 28 - so I would guess that these machine are a good bet for 34K5 presser feet - but again I only can guess. Other than that the standard roller feet you get on Ebay (they sell em for Singer 17, Singer 31....) will fit since the roller is adjustable sideways. In some cases you have to adjust the presser foot bar hight. The only original presser foot that came with my 34KSV5 is this one - but it has no number but parts list will tell you. BTW - the standard long shank feet I use for my Singer 307G2 do not work.

-

I would assume an early Rafflenbeul or maybe a modified MS55 / MS200 - but I´m not sure since pictures are very small . There seems to be a tag on the lower right side....

- 9 replies

-

- sewing machine

- antique

-

(and 3 more)

Tagged with:

-

the 34KSV5 is the same machine - I know someone in Germany with a 34KSV6 and we both have the same machine - difference probably was just that the machines came with different accessories. So you can use the 34K5 Manual and parts list..

-

335 “hanging up”during cycle

Constabulary replied to Hockeymender's topic in Leather Sewing Machines

do you have the binding in different stitch length or is it probably just the longest? Maybe foot lift is too high during cycle? I´d try reducing the stitch length a bit and try to lower the foot lift during cycle - both just a guess.