-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

I guess you mistyped 226. From what I see it looks like a Seiko CW-8 or Consew 227R or similar. The timing belts are readily available on Ebay or from most industrial sewing machine dealers. The Seiko # is 10621 . IIRC they are the same as for the Singer 111w156 (#224195). I do not know if you have a manual that explains the replacement of the timing belt but the Consew 227R manual does but seems there is no timing mark on your machine. Anyway, here is the manual, hope it helps. Consew_227,_223_Manual.pdf

-

Singer 153k103 stitch length adjustment

Constabulary replied to Lugubrious's topic in Leather Sewing Machines

Please let us know if and how your problem got solved. Always good to have a feedback just in case someone else will have a similar problem. -

Singer 153k103 stitch length adjustment

Constabulary replied to Lugubrious's topic in Leather Sewing Machines

The broken pin is the problem as it seems. I´m not sure if you can replace the pin, the knob may be hardened. And I do not know if the spindles are still available. I have one but I´m in Germany and it is from a Singer 111 machine not sure if the stitch numbers are the same. Anyway, I would check with Bob Kovar from Toledo Sewing Machines. He replied in this thread as CowboyBob (see above). He may have some old stock parts. If he has none we maybe can talk. -

Bernina 217 6mm to 12mm zig zag

Constabulary replied to AndreaIbis's topic in Leather Sewing Machines

Very interesting! I´m wondering if this kit is still available and how many hundred € it will cost. -

I am looking for advice on how to add a coin to a keychain

Constabulary replied to sgtfury488's topic in How Do I Do That?

I once made this key fob with a Singer badge (stole the idea from someone else) and some aged leather. When you use a coin I would solder 4-6 small loops to the rim or metal tabs to the rear side of the coin so it cannot fall out. Know what I mean? -

Singer 153k103 stitch length adjustment

Constabulary replied to Lugubrious's topic in Leather Sewing Machines

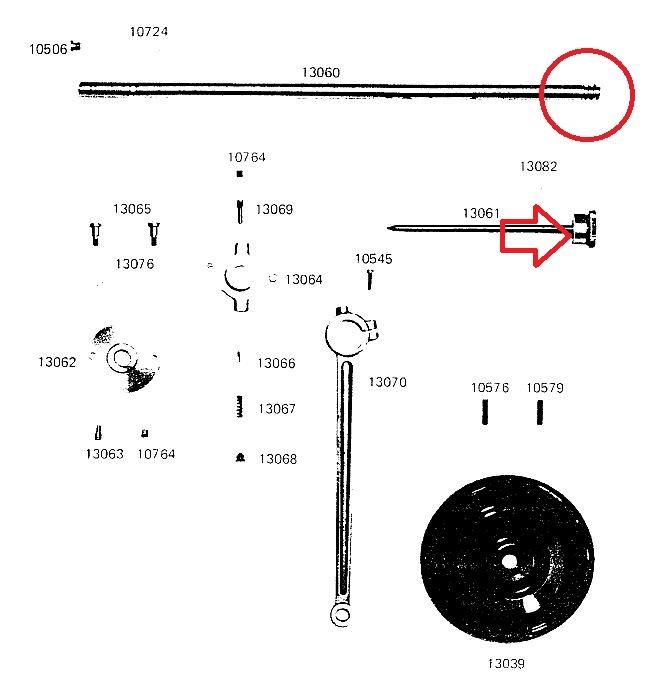

Yes that is the spindle. But don´t mess the tip with a Dremel. What you see on the tip are traces of part # 13066 that pushes against the tip when changing the stitch length. Not sure if you got me right. There is a short coarse thread on the end of the top shaft (red circle) and there is a small pin inside the knob of the spindle (red arrow). And this little pin has to follow the thread when you turn the knob for changing the stitch length. -

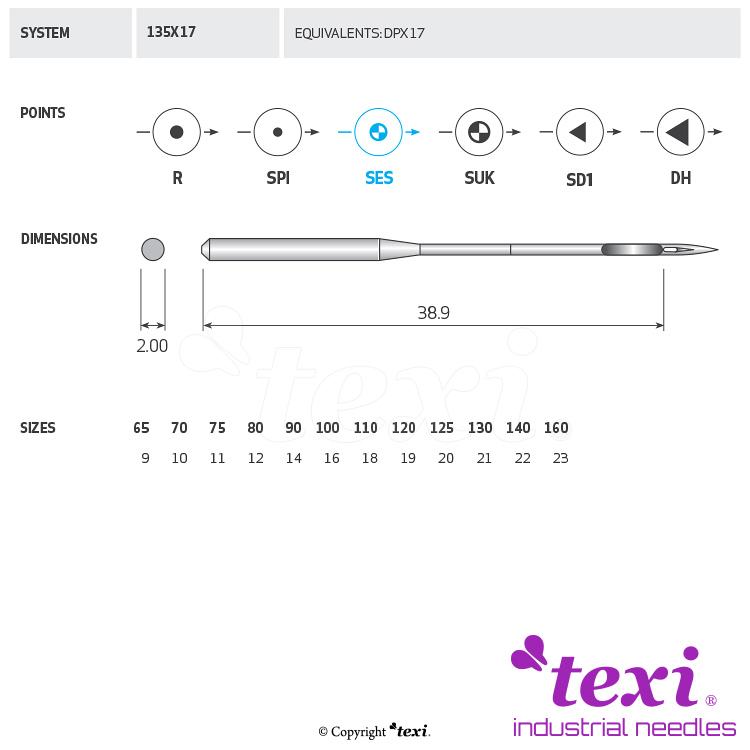

needle system question for 111W156 Singer

Constabulary replied to bnsmith's topic in Leather Sewing Machines

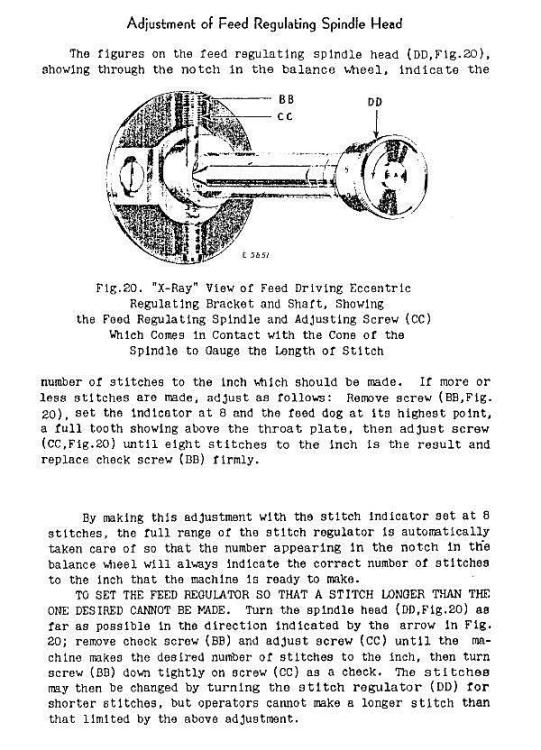

The pictures are from the Texi website. I just googled the needle system and checked "Pictures" on Google. You will find similar pictures from DOTEC or Groz Beckert and other manufacturers as well. 0,8mm sounds not much but can make a huge difference when the needle bar height is not set correctly. When not properly set it may cause skipped stitches meaning the hook tip does not catch the top thread loop. 135x17 and 135x16 are the same needle in in their dimensions but have a different needle tip. 135x17 is for fabric / woven materials and 135x16 is for leather. R + LR are shapes of the needle tip (note "Points" in the above pictures) . R = round tip (point) which mainly is for woven materials LR is a leather tip (point) L= leather R= Right twist. There are many other "Points" depending on what materials you want to sew and what seam appearance you wan to achieve. Needle systems, sizes and needle points can be very confusing when you are new to the sewing game. Check this to figure what cutting points for leather are available and how different the seam appearance can be. https://www.schmetz.com/en/industrial-needles/needle-compass/cutting-points/ -

Singer 153k103 stitch length adjustment

Constabulary replied to Lugubrious's topic in Leather Sewing Machines

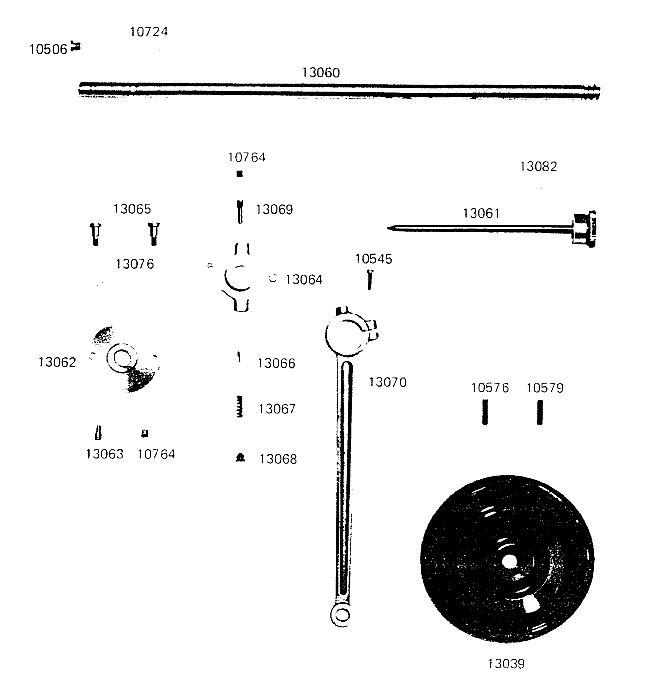

I think the screw you show in your picture is the screw CC which comes in contact with the spindle. What is missing is screw CC. This is from a Singer 153 parts list. So your screw with the long unthreaded end is CC / # 13069 and what is missing is screw BB / # 10764 which locks the screw CC. Make sure the parts 13066, 13067 13068 are present as well and noting in the mechanism is gummed and everything is well oiled. EDIT: Also check the threaded end of the top shaft (where the spindle goes in) if it is undamaged and the small pin on the inside of the spindle knob is present and is following this thread when you change the the stitch length. -

Singer 153k103 stitch length adjustment

Constabulary replied to Lugubrious's topic in Leather Sewing Machines

-

needle system question for 111W156 Singer

Constabulary replied to bnsmith's topic in Leather Sewing Machines

the 135x16 / 135x17 is slightly longer than 134-35. Depending on how the machine is adjusted it is possible that both needle systems work w/o changing the needle bar height. But I´d recommend the 135x16 / 135x17 needle. Check the manual for the needle bar height and needle Hook timing and set is up as recommend for 135x17 / 135x16 - thats what I would do. The difference is 0.8mm - see pictures. -

2 Spools, yes but its is still a machine with a hook and "bobbin". But indeed very impressive!

-

New member from England signing in.

Constabulary replied to unclealec's topic in Leather Sewing Machines

@AlZilla you didn´t right? It is a 220V / 230V Version with EU plug. EDIT: sorry now I got it , and . is the other way around on my end. -

New member from England signing in.

Constabulary replied to unclealec's topic in Leather Sewing Machines

@nejcek74 since you are from Switzerland, a German shipping address near the border may be an option for you. Check this out: https://www.grenzpaket.ch/ https://www.grenzpaket.ch/grenzpaket-lieferadressen https://www.swiss-paket.de/ https://www.swiss-paket.de/filialen.html -

New member from England signing in.

Constabulary replied to unclealec's topic in Leather Sewing Machines

interesting - must be because of IP or geo targeting. On my end they show 74.99€. But maybe you find something similar on Aliexpress on your side of the pond. Yes or on Temu or VEVOR... you name it. Or maybe wait for the Black Week. In October I paid ~68€ for these motors. -

TACSEW T111-155 help: knee lifter rod and manual

Constabulary replied to sinneD's topic in Leather Sewing Machines

maybe its me but what dowel pin are you talking about and why does it need a cap - sorry but I have no clue of what you mean. -

New member from England signing in.

Constabulary replied to unclealec's topic in Leather Sewing Machines

I´d say 99% of the sewing machine rookies do not have fun with clutch motors. When I stared my sewing machine journey I even sold machines that were too fast because I had no idea that servos existed. I regret some sales now but in 2012 I found this forum and learned so much ever since... Really - you do not want a clutch motor nowadays. A servo is what you want! You sometimes find unbelievable cheap servo motors on AliExpress. Just recently we had an offer of 68€ for a 750Watt Motor - that is approx 1/2 of what you pay elsewhere and even incl. shipping . Not kidding. But they cost a bit more now but still cheap. I bought 2 of them just because they were so unbelievable cheap. The prices may vary depending on your location and have an eye on shipping cause some ship from China, somewhere in the EU or from a warehouse in your country. This one is offered for 75€ incl shipping to Germany (not sure if you see the same price) https://de.aliexpress.com/item/1005007219685444.html -

I would say you already have the better machines. An upgrade IMO would just be a CLAES patcher with large hook (#3 or #300 subclass) or a 29K72 with large hook but they are still patchers! If you want to sew heavier than they can then I would the look for a real leather machine like the Juki 341 clones or something like a Cowboy 3200 or 3500.

-

which 29K do you have? If it is a 29K7x then I´d stick with it. Patchers are repair machines and not machines for producing things so do not expect a serious heavy duty machine. If you love ancient machines (I do) then it is a nice machine - really. But when something breaks you only can get parts from a 2nd machine or you find used parts somewhere. I haven`t yet tried if my 29K71 or the Dürkopp 17 sews thicker but no matter what I´d keep my 29K71. My D. 17 still needs some attention but it is sewing and I tweaked it so it makes a longer stitch but that just a nice feature but nothing I really need. Also if you buy it make sure it has a functional hook cause they are no longer available - in some cases you my find a hook that you can modify but do not rely on that.

-

I doubt that it is technically possible. if it was don´t you think someone alreday had invented something in the last 200 years. Well I´m not a technician but in my nut shell I cannot figure how it could work. When you look at min 3:18 (approx) you will see the hook and bobbin case.

-

This is a Dürkopp 17 patcher. They came with 3 different size hooks / bobbins. Parts are no longer available since about the 1940´s / 1950´s nothing is made for them anymore. The machines are really nice when clean at set up properly. I once restored an earlier short arm version of it. You find a list of sub classes in this thread here: Find more about the Dürkopp 17 here: https://www.google.com/search?client=firefox-b-d&q=dürkopp+17+site%3Aleatherworker.net

-

Casting is different yes so lets say the Singer 7 is the predecessor of the Seiko but it shares certain parts with the earlier Singer 7.

-

Head weight is 58Kg - see attachment 205_D_GB_F.pdf

-

Is Pfaff 331 a good all-round sewing machine?

Constabulary replied to trikvart's topic in Leather Sewing Machines

alright so you know more than we do. Test it before you buy it. That's the best advice cause we do not know what else is controlled by air or solenoid and we do not know the machine subclass to figure how it could be set up. I mean that - test it to see if it suits your needs. But let me say this - these old (approx 1990´s) EFKAS are nice when they work but can be a a pain to repair (expensive if possible at all) and replacing motors that control "bells & whistle" can be challenging and expensive too. If it was me I most likely would not buy it - BUT again better test it and see what it does but if the motor cannot control all installed bells & whistles don´t buy it. My 2 cents. -

maybe it is a chain stitch machine then it does not need a bottom thread. EDIT: No - has shuttle hook so it has a bobbin. http://www.hightex-solution.com/a/Products/machine/Programmable_sewing_m/2021/0218/208.html they wound the bobbin from the blue spool. See the bobbin winder with blue threaded bobbin on the top of the machine? Using 2 spools is quite common in the sewing industries. One for top thread (you can leave machine threaded) and wind the bobbin from the 2nd spool.

-

Is Pfaff 331 a good all-round sewing machine?

Constabulary replied to trikvart's topic in Leather Sewing Machines

that appears to the a short stitch length / fixed stitch length machine. Looks like stitch length lever is missing / has none because of a fixed stitch length. Note the short cutout in the throat plate so it cannot be a long stitch length. I doubt you will be happy with it. Maybe a flat bed machine is better for you flat work. In another forum a member once called machines like this "savantism sewing machine" cause it can do ONE task very well but is not good for other tasks.