-

Posts

210 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Squilchuck

-

Another thing occurred to me. Some parts of the hide stretch more than others, e.g. belly leather. Butt and back stretch least. --John

-

Most veg tanned leather will stretch a bit or loosen with heavy use. I've inserted a piece of leather in formed knife sheaths, with a bit of glue or double-sided tape to hold, to tighten up the space. The owner had oiled the hell out of it and the leather softened. --John

-

Do yourself a huge favor and spring for Hermann Oak leather. I used cheaper leather to save money when I started, but soon found that using the best leather saves time and frustration - it looks, carves, colors, cuts, and molds the best. You'll put a lot of time into making the saddle, so spending a few dollars more on good leather will give you a saddle to be proud of! I buy from Montana Leather or Hide House. -- John

-

Like Bikermutt I have Weaver Heritage splitter. Very sharp out of the box and works great. I use it all the time. --John

- 3 replies

-

- belt

- skiver splitter

-

(and 5 more)

Tagged with:

-

If you call the closest store they'll go measure the ones you want. Otherwise, hard to say without knowing the exact product and square footage. --John.

-

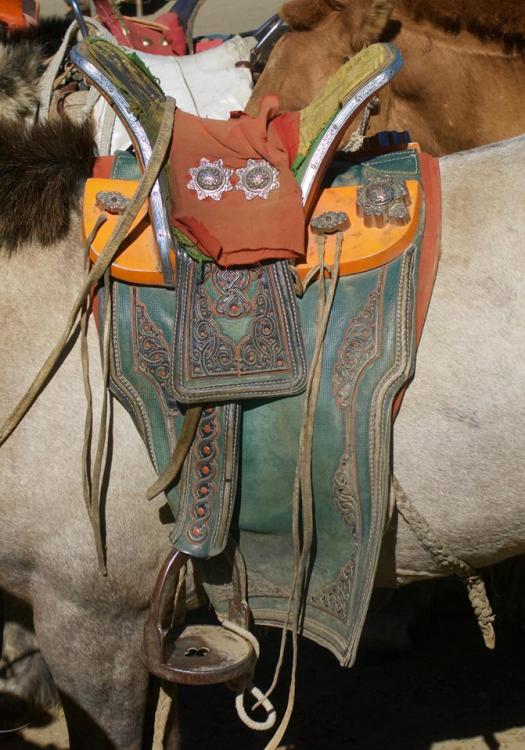

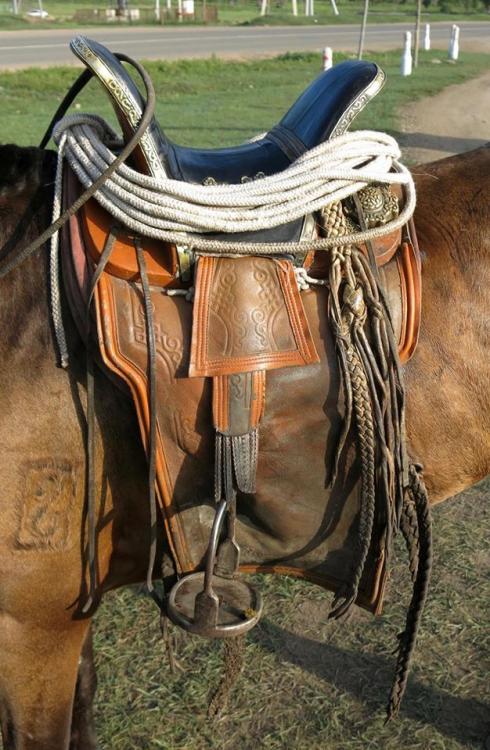

Check out these Mongolian saddles and trees. Photos come from a range conservationist friend who has spent lots of time working and riding in Mongolia with herding nomads. No local saddle for him - he has mostly ridden older Bona Allen saddles and now rides the shown western saddle custom made for him by Shooting Star Saddlery, MT. --John

-

All the HO tooling leather I have bought has been excellent on both sides. I only buy HO now. I would have sent back the side you got if the flesh side was rough. Maybe you can split it a bit to shave off the roughness? --John

-

If you buy one book make it the Stohlman book. A wealth of easy of follow instructions and explanations. Great hand-drawn illustrations. His way of making some saddle parts is unique, based on my novice experience and comments from others here, but many processes are pretty conventional (like making stirrup leathers and fenders). --John

-

buckstitching causing uneven edge - how to avoid?

Squilchuck replied to thekid77's topic in How Do I Do That?

Only buckstitched a few times, but a few things that might bunch the leather occur to me. Pulling lace too tight. Lace too thick or not beveled. Holes too close together. Lace not dampened to make it conform. Tandy sells a great short booklet on buckstitching. Seems you could dampen completed project and pound gently --John -

Use high quality skirting leather - Herman Oak and Wicket and Craig are the best. Weaver also sells Chahin which seems to get some good reviews. Weight (thickness) might depend on the rest of the saddle: 11/13 or13/15 Oz. Use bark tanned shearing I buy from Montana Leather, Hide House, and Weaver. Get a copy of Stohlman's saddle-making book from Tandy or Harry Adams book to show you how to do saddle work. I use self-tapping cabinet screws, lathe nails, or sometimes blue tacks --John

-

Great idea! In had the same issue making a 9' long leash. Didn't think about cutting it like lace - I cut two pieces and connected with a glued and sewn splice. -- John

-

Also, the thickness seemed a bit less than advertised. Definitely not as dense as real shearling, hence less cushion and durability on a saddle.

-

I bought some from Weaver. Don't recall the price, but inexpensive and seemingly good quality. Weaver sells quality goods. I used rubber cement. I don't use it for saddles, though. Why not use the best bark-tanned shearling for a saddle, instead of imitation, unless price is a factor on a replacement job? I'd get two yards. --John

-

One more question. How did you like the Chahin leather? Can you compare it with Herman Oak?

-

Very nice! Is that the Stohlman design with your added touches (binding, etc.)? The satin finish looks great - how did you treat the raw leather?

-

I did a standard cantle binding on the first saddle I made and worried to death about the look of the backside stitches. So, I decided to use the hidden back stitch technique in Stohlman's book. It looks great and made stitching much easier not finessing the back stitch. I'm making a third saddle now and suppose I should buck up and take the challenge of an exposed stitch line, hmmm. -- John

-

Barry King has great customer service. My BK swivel knife and blade work great. Contact him w your problem and I'll bet he sends you a new blade. --John

-

Thanks for the education! All good reasons for bucking rolls. I like that you can take them off. I am making a Wade saddle now to see how I like 'em and use for ranch roping. Just might make bucking rolls too. --John

-

Nice work. I never have understood bucking rolls. Use a nice slick fork saddle then put bucking rolls on it? Why not just get a swell fork saddle in the first place? Do you just like the look of them? Educate me please! - John

-

Cobra Steve and Leather Machine Co. WOW!!!

Squilchuck replied to RedsinTrouble's topic in Leather Sewing Machines

The only time I've broken needles is stitching through existing holes while refleecing a saddle. The skirting was slightly bent and deflected the needle onto the feed dog - broken needle! I broke a couple before figuring it out. So, your story rung a bell. My Cobra 4 works great and I have always gotten great service from Steve and his staff. I especially appreciate him coming up for the Pendleton show, which gives me a chance to ask questions in person. -- John -

I have tried to use the smallest loop of my Osborne compass groover for this task, but it shaves leather off the side of the groove, especially with old worn skirts. This doesn't happen with the patent leather tool? I suppose you use a #1 groove or is #2 best for the large thread used for skirts? -- John

-

Split the bottom of twisted stirrup leathers?

Squilchuck replied to Squilchuck's topic in Saddle Construction

Thanks, Ron. I cut the legs ten inches based on the JW video where he twists the leg but does not wrap. I fastened the leathers but have not twisted and set them. I see what you mean - not enough length for a latigo wrap. I have the Pete Gorrel book from Leather Crafters journal and he recommends a 12" leg as you did for a wrapped leg. I should have read that chapter before cutting. Well, I'm learning all the time! I'll twist and set without the wrap and see how I like it. At worst I buy another skirting side and cut new fenders. -- John. PS I decided to not split the leathers. -

Split the bottom of twisted stirrup leathers?

Squilchuck replied to Squilchuck's topic in Saddle Construction

Leathers are full length and 3" wide. The section from fender bottom to buckle is 10" long. The saddle is a Wade intended for ranch roping and general use -

Do you split (thin) the bottom of your twisted stirrup leathers, and, if yes, by how much? I am working on a third saddle using Jeremiah Watts' video, along with the Stohlman and Adams books. JM says to split the bottom 24" of the stirrup leather where it attaches to the fender to reduce bulk at the bottom of fenders that are turned/twisted when set, but he does not say how much to thin the leather. I did not twist or split the leathers on the other saddles I made. I am using 11/13 oz HO skirting on this saddle, so wonder about the need to split to reduce bulk and facilitate the twist and set. Got any advice on whether to split or how much to thin 11/13 oz skirting leathers? --John

-

I've thought about buying one too, but just don't cut enough rosettes for the cost. Then too maybe you want several sizes. Stohlman shows in his saddle making book how to punch your own with a drive punch ground into a half circle. Doesn't take long to make a rosette and I can make them any size I need for the low cost of a drive punch. -- John