-

Posts

1,229 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Halitech

-

Finished off another rifle stock butt cover. Made from 6oz veg tanned leather, dyed Chestnut in color. Feathers are hand drawn and tooled. End is hand stitched to cover the back of the stock. Has 9 loops to hold rifle shells in the 30-30, .303 range size. 7.62 will also fit but very tight. I also used the tandy lace cutter to make the lace from some 4oz drum dyed black leather I had kicking around.

- 12 replies

-

- rifle

- butt stock

-

(and 1 more)

Tagged with:

-

you could be right, I know I have seen someone do this pattern without any other tools and I haven't seen the mini5 you are talking about so not sure how it would look if he got off alignment.

-

-

sure is but it looks great when you can do it right (which is why I'm not touching it lol)

-

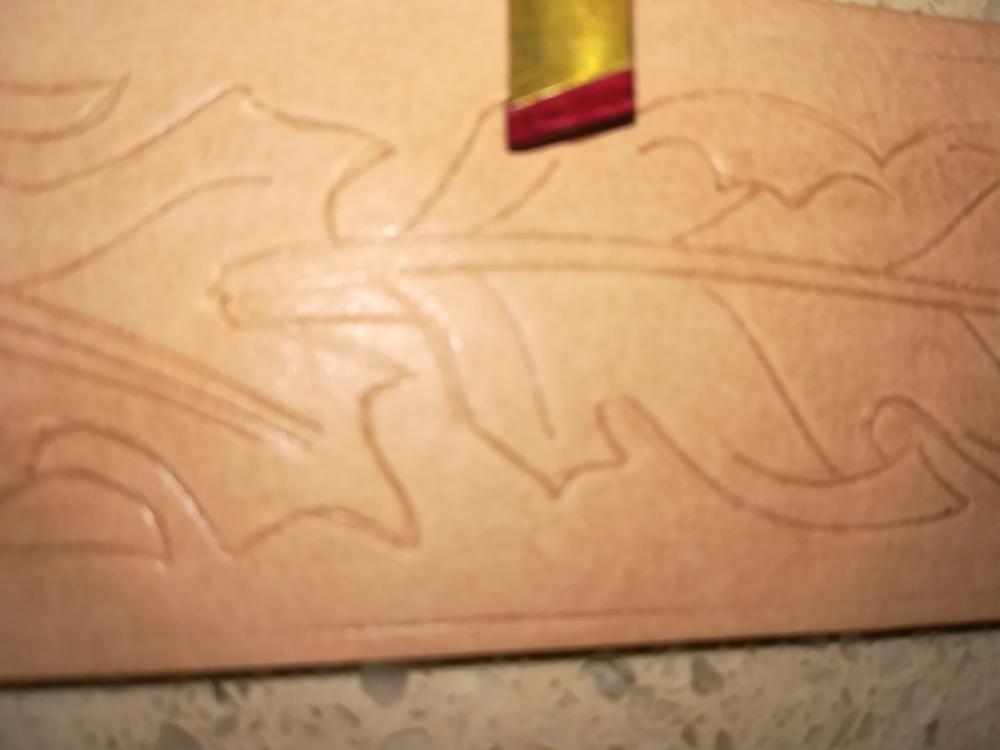

swivel knife, a ruler and a beveler if you look closely, you can see the knife marks on some of the ends where it meets the cross piece

-

I know this is not really my work but wanted to show off my "new" Tandy swivel knife with a genuine ruby blade and a part of a belt I carved using the new to me blade. I have to say, this old knife swivels like a dream compared to the new ones I have that seem to almost growl when turning the blade.

-

if you are burning when using a dremel, you have it turning too fast. Honestly, if you aren't burnishing, there is no point in applying beeswax to the edges. If burnishing is that hard on you, consider using edge paints like these https://www.tandyleather.ca/en/product/eco-flo-edgeflex-8-5-fl-oz-250ml http://springfieldleather.com/Edge-Kote-Black-4oz

-

Coptic Stitch Sketchbook

Halitech replied to Grey Drakkon's topic in Books, Journals and Photo Albums

looks great Grey. How will the linen thread stand up over time? -

I make mine from 6-7oz

-

I love their thread, been using it for almost 3 years now so I know what a great score you pulled here. I wish I had a reason to go down, I'd be loading up as well

-

TONS of snakeskin hides for sale!

Halitech replied to heavyleathernyc's topic in Exotics, Reptiles, Furs and others

wish I could get this shipped north of the border -

I would suggest that when you build another one, use the same closure on both ends so you get the continuity. The other option would be to sew the end going around the belt.

-

you got my idea perfectly the hole you cut for the button stud though could be an issue as it wears and it may stop holding. Typically I punch a hole a little bigger then the neck size then cut a small slit about the same length as the widest part of the stud. Works pretty good and is about the same as the tool tandy sells for them

-

not at all, use a single piece of 4oz veg tanned, cut it to the length you need, tool.dye, etc. Then finish the flesh side by burnishing like you would the edges. I've done the call center thing and it would take decades of wear to wear out 4 oz leather with just the weight of a headset hanging from it.

-

Not going to say Paul Long isn't as good as you say Tony but google shows he does a pancake style sheath and that is it. With a pancake sheath, no, you shouldn't need to wet mold the leather however, that is not the only style sheath and I would say wet molding is done probably half the time a sheath is made.

-

you could go with 1oz lining leather and it would hold up fine. I would suggest probably 4oz veg tanned about 7/8" wide and a 1 inch D ring. Or, extend your pattern by 4 inches and make a loop to go on your belt

-

What thread would I use to line a gun belt ?

Halitech replied to Sorcerer1's topic in How Do I Do That?

sorry to hear about your health issues. Far as the thread, I can't find any #400 thread info so I'm not sure how thick it is. I usually buy my thread in either 0.8mm or 0.030" but I can't compare to what you are using. What brand is the thread you are using? -

pretty much unless you want to invest in a electric edge burnishing machine and burn the edges

-

I know when I last ordered from them, paypal was not an option but I had to call and make the order anyway because they were having an issue with shipping options to Canada and they were bale to send out an invoice to be paid by paypal and then they shipped. Might not be the case now but I don't think paypal was on the site at that time.

- 10 replies

-

- slc

- springfield leather

-

(and 1 more)

Tagged with:

-

you will literally pull your hair out if you try to burnish chrome tanned leather. Chrome tanned does not absorb water so you will be better off using an edge paint or some other form of finish.

-

What thread would I use to line a gun belt ?

Halitech replied to Sorcerer1's topic in How Do I Do That?

I'm assuming that is a machine thread. Is there any reason why you think you can't use it? -

What thread would I use to line a gun belt ?

Halitech replied to Sorcerer1's topic in How Do I Do That?

what thread do you normally use to sew things together? -

Roper Wallet

Halitech replied to Sofaspud's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

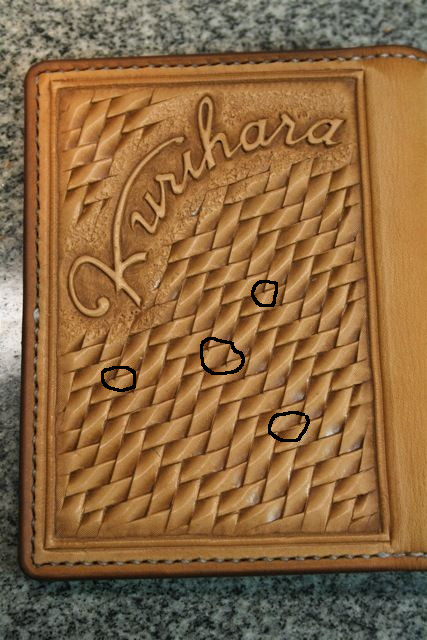

nice job on your lacing and the serpentine border. You did pretty good on keeping the tri-weave straight but you can see areas where it's off a bit once you hit the edges. The tri-weave is a bugger to keep on track. -

Let me see if I can explain it better. Instead of having the buckle attached to the body, attach it to the end of the tail and then put the adjustment tail on the main body of the strap. Like this one. That way, everything hangs down naturally, not flopping over and down like yours will once the leather starts softening up