-

Posts

5,016 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by bikermutt07

-

Irish theme knife sheath

bikermutt07 replied to corkscrew's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That looks great. -

Bandolero for my father

bikermutt07 replied to Colt W Knight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Oh hell yeah! -

Sealing (Not Burnishing) Chromexcel Edges

bikermutt07 replied to superpacker's topic in How Do I Do That?

I think that looks really good. I didnt have tokonole back when i did mine. I dont think i ever tested it on cxl. -

Help with type of Leather for a purse

bikermutt07 replied to BentleyLeather's topic in Getting Started

Unless you plan on tooling it I would get something a little more weather friendly. Acadia has some great deals just about every day on Instagram. Most of their stuff seems to be in the 4-6 range and makes beautiful totes. .02 -

Pink Floyd themed wallet

bikermutt07 replied to datdraku's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very clean looking execution. I like it. -

Gary’s Casino

bikermutt07 replied to GrayHallidayJr's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Yeah, he hasn't stopped in for awhile. You should see some of his other stuff. -

Sealing (Not Burnishing) Chromexcel Edges

bikermutt07 replied to superpacker's topic in How Do I Do That?

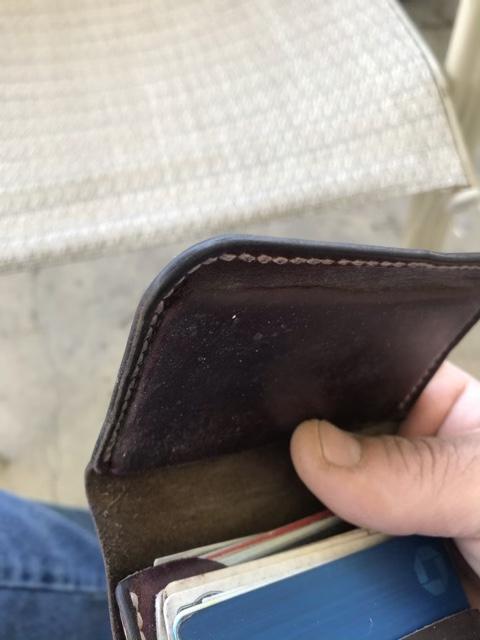

My thinking is since they are hot stuffed with tallow, waxes and such is that they are pretty impenetrable to begin with??? Am I thinking wrong? Here are pics of the wallet I have been carrying for 2 years in burgandy Horween cxl horsebutt... And a few just to show the wallet while we're at it. -

Used straight or round knife on a budget - brands?

bikermutt07 replied to GeneH's topic in Leatherwork Conversation

Looks that way, I also ordered the 19 dollar knife from Wuta in hss. I have been recommending his starter set which is really well thought out. I have a few of the tools in that kit and they are really great for the price. So, I really need to check out the knife if I'm gonna keep recommending it. This is the kit... https://rover.ebay.com/rover/0/0/0?mpre=https%3A%2F%2Fwww.ebay.com%2Fulk%2Fitm%2F153332451784 Welcome. -

My scale is not that good. I weigh in once or twice a week. The body is a weird machine. Weight fluctuates all throughout the day. When I weigh in it is first thing when I wake up after taking a leak. Even just an hour later will show an extra pound or two.

-

Sealing (Not Burnishing) Chromexcel Edges

bikermutt07 replied to superpacker's topic in How Do I Do That?

My experience with cxl is limited to the horsebutt. The wallet I carry is made from it. There are so many waxes and oils in it that burnishing really didn't do anything for it. I didn't try any edge dressing or paint because I figured it wouldn't stick. The items I did actually kind of burnished themselves over time. One wallet I carry daily, another I sold to a co-worker. Both seem fine. This may be an example of leather that needs heat to seal the edges? I wish I had a better answer for you. Someone who knows more than me will be along, I'm sure. I will be following along myself for a better answer. -

Gary’s Casino

bikermutt07 replied to GrayHallidayJr's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Glad to see some more of your work. You've been missed. Excellent as always. -

Used straight or round knife on a budget - brands?

bikermutt07 replied to GeneH's topic in Leatherwork Conversation

It takes a little practice to do the push cuts. But, it is not difficult to learn. Yes I have used mine many times around a template. If you strop those surgical blades you will find them much easier to use. -

I don't have any of their snaps yet. Just jiffy rivets, buckles, and d rings so far. I plan to make an order soon, but I doubt they will fit. We'll see. Even if line 24 snaps work in the Goldstar does, it doesn't mean other sizes will. This may turn out to be a costly upgrade.

-

After placing an order with Goldstar and the buckle guy I see there isn't really much contest. I have used Tandy hardware mostly. Then wound up with a Goldstar press and hardware from a lot sale. The press seems fine. I ordered some non press type hardware from Goldstar and while it was cheap, it was no bargain. Most of the stuff I wouldn't want to use. So, for that particular project run I spent some more money and tried the buckle guy. It was no comparison. Solid brass everything and built like a Sherman tank. I will be trying to use their stuff exclusively from now on. It will be tough though, I have a lot of hardware from Tandy, Goldstar, and a few random things of unknown origin. Even buckle Guy's hand rivet setters are a real cut above. Cnc machined setters and anvils. Meaning they left no unsightly rings on the surrounding leather. I was very impressed.

-

If I'm reading the picture right? It looks as the rivet is just being used as a stay for that clip. If so it would take a shearing move to ever tear it out. That would take much more force to remove than say the the shield rivet that Fred shows an example of. Which, he has assured us is plenty strong.

-

Sounds like quality stuff.

-

I made a belt for my son

bikermutt07 replied to Firewalker's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Nice. -

There are newer products every day. OSB is chips and glue like he has on the interior and ceiling. It lasts for awhile in the weather. Used quite a bit in residential framing. Particule board is sawdust and glue, MDF is medium density fiberboard (paper and glue). I wouldn't have anything out of MDF or particle board. More about the newer products... I did some sub floor replacement recently and it was spec'ed out with some OSB that is guaranteed for six months before needing to dry in the structure. Meaning it can get weathered for six months before you close in your structure. Pretty impressive.

-

There is a company that is selling lots of machinery right now in the for sale section. They bought an old building that was used for saddle and tack.

-

Used straight or round knife on a budget - brands?

bikermutt07 replied to GeneH's topic in Leatherwork Conversation

I messaged Kevin on this exact posting and he said he had them available in left hand models. So, now I have one of those coming too. -

Used straight or round knife on a budget - brands?

bikermutt07 replied to GeneH's topic in Leatherwork Conversation

Well, Wuta offers this one in a Lefty model. I have one on the way. https://rover.ebay.com/rover/0/0/0?mpre=https%3A%2F%2Fwww.ebay.com%2Fulk%2Fitm%2F153396227566