ljk

Contributing Member-

Posts

201 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by ljk

-

Please make a note on bobbins. Large bobbin machines such as 211 singers and Consew 206 are all susceptible to warpage with too tight a tension when winding the thread. Not likely with G or L bobbins. Put a new bobbin in that machine and see how it sews.

-

I would check with Melody Machine in Calif. Also would check whether you have a filter and if changes were made to aftermarket. Also lube machine well before starting. If it moves or pivotes lube it. A dry machine puts tremendous loads on the pump.

-

There is a bunch of stuff you need to check. Uwe Grosse has a excellent You tube video on timing Consew 225. Check your bottom tension using a tiny screwdriver to lift the front of tension flap on hook, just enough to blowout any debris. Than check if tension increases. Also the hook basket may have debris and thread pcs under basket. This is fairly easy if you have done it dozens of times. Don't lose those tiny screws. To get the best help take pictures of thread path, and hook with needle bar at top position Also clean tension discs. I'm sure more help is coming.

-

I also share your interest Mostly for shoesoling. Most race track tires are non radial as are motorcycle, atv tires and trailer tires. Speedway Motors sells tire groovers. I have a dream of taking tire treads remolding with heat and pressure to make soles for shoes and sandals. Keep me informed if you can. tx Lynn

-

I glue a pc. of 2mm teflon to the toe of my shoe patcher. If you scuff it with sandpaper on the back side and clean the toe with acetone or lacquer thinner you can glue it down with good results. I've used both contact cement and epoxy. You only need about a inch or so forward of the pivot. Round off the teflon so it won't grab on the edge. If anybody has a source for gluable teflon pls. let me know. You can do a lot with a shoe patcher using this slight modification. Leather drags.

-

This is a common issue on this forum. There is 3 issues # 1 tension, most machines release tension by knee lift and or by lifting lever. You have to sew with no tension release, and you may consider after stopping pull thread tight. I have adjusted my tension release at the very top of its travel. #2 I use SD1 needles seems to work with minimum eruption on the back side of the leather. #3 I use Merrow floss commonly used to put edge on patches. Available in small spools from red Rock Threads online. This thread is all poly, strong. and is fairly thick. It has good shine and shows well wallets and bags. You may not duplicate the saddle stitch but can get close.

-

Go to ebay-leather-punches multi punches in box DIY 39 should be on first page. tx Lynn

-

Can this clicker press be used for leather working

ljk replied to TomWisc's topic in Leather Machinery

This a USM model C. I've used this machine for twenty years. I sold my Fipi and Swabe when I sold my business 14 years ago. My machine has been reliable with only one used part from Melody Machine.I also got a die bender and punches to do steel rule dies. This machine is susceptible to double clicking after about a 1000 clicks on small dies. don't see them in factories for that reason. They work with a internal clutch which heats up. Formerly used for cutting shoe soles. The primary problem is stopping on the die, however there is a release mechanism at the, top most just back it off with a large pipe wrench. Lot ta marks on the hub. It's my pet machine, most use 220 single phase, you can replace with a 110 motor. Manuals are available on EBAY. If it was me not over $1,000 and it has to work. tx Lynn -

She’s broke....Singer 111w155 parts needed

ljk replied to Glaciersew's topic in Leather Sewing Machines

I don't have the part. sorry Lynn -

She’s broke....Singer 111w155 parts needed

ljk replied to Glaciersew's topic in Leather Sewing Machines

I see what you need. I will look tomorrow and let you know. tx Lynn -

Singer 111w155 stitch length selector “wacky”

ljk replied to Googledave's topic in How Do I Do That?

If you turn the hand wheel backwards the stitches will shorten. That said if it stops 5spi pulling the handwheel towards you and you can do only that amount it might be frozen . The selector is also attached to the arm that regulates stitch length. So you have to check that. If it was me I would soak in PB blaster. Then I would attach a vice grip to the shaft maybe protecting it with a piece veg. I would than center the selector and rock back forth and feel the movement. no changes soak again ! Don't turn so hard it that will damage the belt. -

I suggest you google Pantone color. Pick your color and then ask your thread supplier if they can match it. Another way is go to a paint store and match your item and mail chip to thread supplier. My last choice is 3 spools of poly home machine thread most cases it will work on a patcher. good luck

-

How to remove rusted seized needle plate screws?

ljk replied to Kryptonite's topic in Leather Sewing Machines

Soak with PB Blaster. Keep wet for a couple days. Than use a long screw driver and tap with hammer. You can dissolve plates, screws and other loose metal items with The Works a degradable bowl cleaner. Soon as dry oil well. -

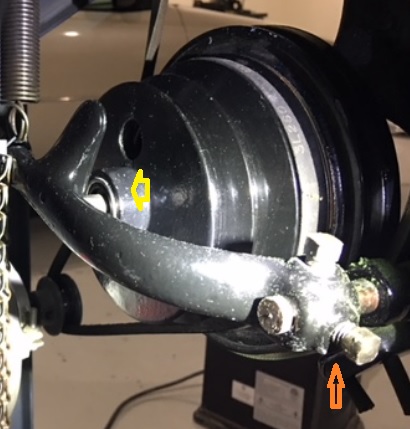

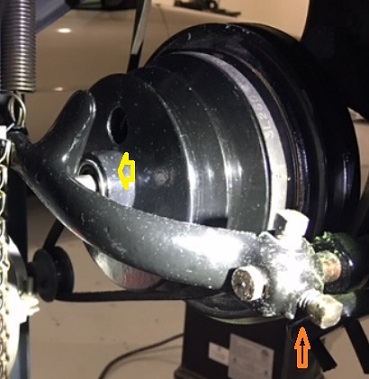

Years ago as a itinerant leather vendor I used a bunch of these jack shaft clutches Currently I run a 111w155, a Union serger , and over lock. They have excellent control and the motor driving the clutch can be easily replaced. Or as ones used with a long belt running outside for some of my Amish friends. I think your problem is. One the bearing at the yellow arrow should turn free when the clutch is disengaged Second adjustment is at the orange arrow to free up movement. I always run a leather clutch belting dry. Make sure the main shaft is getting oil from the well

-

I have 2 staplers back in a corner of my garage in Fl. I'm still in Colo. until Nov. Shoot me a e-mail after Nov. 10 if your still looking. tx Lynn

-

Hello I have downloaded this info which may help your research. One of my trades is auto upholstery and I have been interested in the various leathers used. Why do european cars left in hot florida sun interiors deteriorate so quickly? The site I showed you shows a south carolina location. I know we have car production that of which some are exported. Do they have to meet european specifications. The site specs. veg tanned only and I would like to know how durable it is. I think your research will show that modern leather is corrected, thinner, more flexible, and not as durable. I also think 3rd world countries are making chrome finished splits with questionable durability. Keep in touch tx Lynn

- 2 replies

-

- polyurethane

- pu

- (and 6 more)

-

I downloaded image from e-bay. This type of assembly is used on heavier machines, such as 112, 144, and 145. I would call machine dealers on this site for the parts you need. tx Lynn

-

I have a bunch of Merrow machines. I keep 3 in use for a Merrowed edge for custom patches. Very sturdy machine but not very heavy. I run mine with std. domestic sewing motors. Once set up they are very reliable. Bought my first one from online dealer it ran, but had to feed manually because he ground off the feed dog, bad, bad. They use cams to change stitch length. Of the two girls in the shop one won't use it and one will but only if I'm not available. They have a very good knife system. I use those small storage type racks from Sams for tables. That said a industrial serger 3 thread will work also for your needs. Juki and Siruba are very good. If I set up a Merrow machine It will run properly, however you will probably send it back several times to adjust or repair. Two issues breaking needles (failure to remove material properly) and failing to thread properly. I would sell one for $500. It will be set up. I would require materials to test, includes video prior to mailing. I welcome any comments. tx Lynn

-

I have these two. One with italian mark and one german. Commonly used in the saddle and other veg. leather venues. One is used daily in cutting heatsealed embroidered patches. The single sharpened upper edge makes a downward cut very clean . The other used in my shoe and leather hobby. For example after sewing a wallet I can cut a very clean line along the stitch line. Makes burnishing easier. As long as inside edge is clean or can be cleaned up with minimum removal their useful.

-

This is a twin needle attachment used to add a double stitch to a single needle sewing machine. The one shown I am modifying to make jeans belt loop. The one you have I could use to sew a narrow double line on shoe uppers. Let me know if I could buy one and after trying I will get back to you with feedback. tx Lynn

-

Coming from the world of upholstery when I need to pipe or welt I use a welt foot of appropriate size. For boot side seams and purse piping I used lawn trimmer string. The hardware or big box store has many sizes and it is stiff. Plus you can melt the end and pull an appropriate taper. Lacking the right size foot a zipper or side seam foot will work.

-

Hello I do have a 144w103 in Colorado, have some history. Also have a 111w155 in Florida that was the crinkle 50sh paint. Excellent original condition. tx Lynn

-

I've have or had a Schabe, a Fipi, and a USM model C. I sold my business but kept the C. The C is very fast and reliable but only good for about 1000 clicks per day after that the flywheel gets warm and can multiple click (not good) The Fipi has auto height, I had to replace the trigger (microswitches) The Schwabe has never had anything but fluid replaced, simple design. Both machines run on phase converters. If weight is a problem a Tippman might be a good choice, or a Solar 10ton (check weight) Both can be viewed on Y tube. Best thing is the ability to manipulate a hide around the cutting mat. Those little mechanical clickers.don't look like much to me. My choice Cowboy cb10 good luck LJK

-

I do have a 30-1 It is setup with a gear belt reduction mounted on the back. This was a commercial system available back in the 90s. I used this machine on the bike circuit sewing patches and doing leather repair. It fits into a box for transport and also is used as a table. Has had work on the head will do 5/6 per inch depending in material thickness. Arm I would rate very good. Machine at my shop in Colorado won't be there till middle may. Price $750 If interested let me know and will send pictures when I get to Colorado

-

I made the comment about the (31-19) because there may have been a possible miscommunication between the seller and buyer about the number. I have the short version I use for vamps. I also lengthen the stitches on most of the 33 and 44 series machine I have owned. The 31-15 was the go to machine for upholstery when I started the 111w machines where very expensive. I knew a girl on the bike circuit who used a 31-15 and not just a patch sewer, she could put a zipper in a heavy leather. She was a very accomplished stitcher. Good old machine.