-

Posts

1,653 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by alpha2

-

I get a line with my Craftool Pro edgers, also. The "heel" for want of a better term, is what leaves the line, unless I really lean the beveller over. With thin leathers, I have to put another piece of leather under it, or hold it on the edge of the table to the right amount of lean to avoid the line. Zane, you say the Pro only comes as small as #2, but I have a 1 and a 0 also. The fine is REALLY fine, but the groove is so tiny it clogs with leather that has been cut.

-

I can't wait to see the rest of the process! Thanks for sharing.

-

Some New Small Projects

alpha2 replied to garypl's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Ah! Now I get it. That would work at our range. The first pic made it look like it was 3" thick! Had me scratching my head. Thanks. -

Black is some pretty stout stuff. And Eco-flo works as you would expect something labelled "eco" to work. Hint: you can't get any of the good stuff in California. Not allowed. Allowing 24 hours to dry, buffing until you're totally expended, might work. Next, Tandy is a great resource. If you don't have any other other resources. It is what it is. I personally frequent 3 separate Tandys on a regular basis. But I go in having done my due diligence on this forum. Spend some time on this forum on the dyes and finishes area. Fiebings is usually accepted to be superior to Tandy branded stuff. But, USMC black is not up to that quality, especially if you don't want it to rub off. The other blacks are better. (Seriously, I asked my USMC veteran brother "tell me about black", he said "black is black"). Experience is way better than a minimum wage clerk at Tandy. They have some great stuff there. They also have some worthless stuff that they are more than happy to send home with you. Different stores and different clerks vary considerably. There is some great info here...but you WILL have to make some mistakes on your own. It's just the way it is. As you get some experience, and make some mistakes, you'll pick up some great info, which you will be able to pass along to the next person. I'm here for both reasons...picking up hints and passing along what I've learned, the hard way. Finally, by all means avail yourself of YouTube. There are videos on there that will save you a fortune in wasted leather, materials, and time. Ian Atkinson, Bruce Cheaney, Don Gonzales, Armitage Leather, (Nigel Armitage), and J.H. Leather are some of my favorites for youtube videos. You could spend a fortune on classes, (still not a bad way to go, providing you have the time/money), but this is absolutely free online, and you can stop, rewind, watch again and again). One more thing...better tools equals better work. Better leather, equals better work. Better instruction equals better work. MORE PRACTICE, equals better work. By all means, buy some cheap nasty leather to practice with, then buy some good stuff, but only after trashing some cheap, nasty leather to practice with. Good leather/tools will NOT make up for lack of practice. Enjoy the journey! Jeff

-

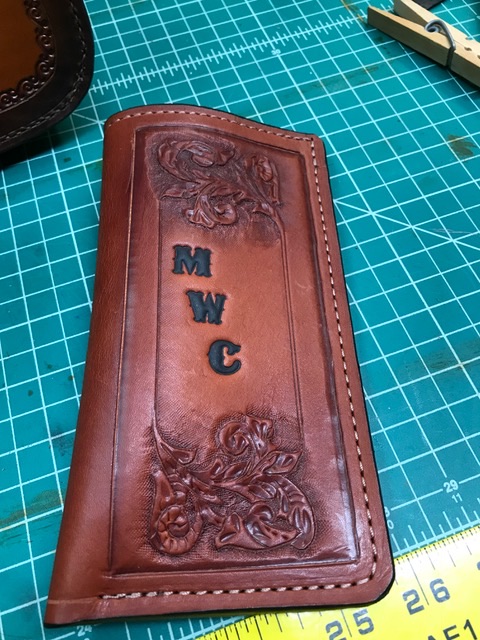

My wife's eyeglass case (plastic) was on it's last legs, so I got to use some of the bridle in burgundy I just got from nstarleather. The liner is pigskin. I thinking I may have to do some additional edge treatment. The flap is okay, but the side edges are, as my Scottish friend says, are crrrrap.

- 1 reply

-

- cases

- eyeglass case

-

(and 1 more)

Tagged with:

-

Some New Small Projects

alpha2 replied to garypl's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

So, how is the barrel rest used? I get the notch for the barrel, but does the thing sit on something? -

Welcome from Fort Fun! As you can see, there is a LOT of info here about machines. Your GMC and I came into being at the same time. It was a very good year!

-

thanks!

- 100 replies

-

First a Lucinda strap, now Margo Price! This forum is on point!

-

So, how can I create a username? Is there a login or something? Can only find info for the admin to program stuff. Thanks, Jeff

- 100 replies

-

You'll be amazed at how much the back side will smooth out with gum trag, or even water, with a good rubbing with a wood slicker, or better yet a glass burnisher. I've noticed that glass burnisher works better in one direction than another. Something about the grain. It takes a LOT of dye to do the backside if you haven't smoothed it out beforehand. The absorption rate is amazing when it's rough. So, yes, you also save on dye! I try to let my dye job dry for 24 hours if at all possible, then buff. If that's not practical, at least overnight.

-

Second attempt at a holster

alpha2 replied to DocDaddy's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Often the seam on the edges can be caused by a too thick layer of glue, or not enough glue... Too thick and it shows because the leather doesn't get close together. Not enough glue and the leather can separate. Also, it's important to pound the layers together when you've glued them. Also you can put a heavy weight on the pieces to hold them tight while the glue sets up. Lastly, it may be the kind of glue you are using. If it's any of the commonly mentioned glues on this forum, I wouldn't worry about that. I'm fairly certain the issue is glue technique related. Having said that, you might be able to rescue this holster, (although it's unlikely any non-leatherworker would notice) with numerous coatings of edge paint with a lot of sanding in between coats. Kind of a body filler approach!- 15 replies

-

thanks, guys! It isn't lined. The thickness of the leather I got from nstarleather was just right as is. I actually like to stitch, and really was going for the added color and overall look. The leather was black both front and back, so I just buffed it up and after bevelling and wet-burnishing, dyed the edges, burnished again and used beeswax for the final burnish. A bit of final buffing edges with a piece of canvas for a little more gloss. I used a craftool 88045-04 3mm chisel for the edges (5spi) and the craftool pro 88057-04 3.5mm (7spi) for the keeper. I was trying to figure out what to use to hold the keeper for stitching, as it's just too narrow to use the stitching clamp, finally decided on an actual handclamp! I wouldn't want to do an entire belt that way, but for something small it was fine. I'm thinking of making a very small stitching clamp for stuff like this. I seem to do a lot of belts with keepers.

-

Greetings and salutations from SW Missouri :)

alpha2 replied to ComputerDoctor's topic in Member Gallery

Welcome! My trophy wife pronounces it "Missour-ah". Now, I have to say, she is the only one in her family to do so. But, she is ADAMANT about it. She's a heck of a cook, so I let her have that. (Like I have a say in that). There is a wealth of knowledge and experience here, feel free to avail yourself of it. Do try to use the Search function first, it's likely you're not the first to have a particular question. -

Not generally related to dye issues, but neatsfoot oil will darken leather. Whether or not it applies to your situation I couldn't say.

-

I've got one bone folder, and the plastic one with the edgers at the end. Mostly I use the bone folder. I also use various other items that can double as folders. Felt pens, spoons, etc. I had issues with boning holsters and the dark lines caused by the tool. I started using a thick piece of plastic between the tool and the leather. You get the same effect without the dark lines. When you look around the shop or house, it's amazing how many items can double as a folder. Various sizes and radii. (I tried radiuses, spell check choked on that. Thought it about it for a second and it came to me!)

-

You're right, the third pic. I had my screen maxed out and only saw the last pics.

-

I have the plastic one also, and a bone one. I use different ones depending on what I'm working on. It's not a one-size fits all kinda thing. I will say I tend to use the bone one before the plastic. 'Cause you know, bone...or plastic. Plastic seems to, plastic. I'd like to have choices like in the second picture.

-

Tandy has a black friday special the 24th and 25th, three for 129.99. They're the craftool pro ones, a 2lb round, a 2lb tapered, and a 1lb flat mallet. 12 per store limit one set per customer. Retail on these is $439.99. Thinking I'll drive up to Cheyenne and pick up a set.

-

Metal does tend to cause burrs on the backside. This will affect thread, big time.