-

Posts

794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DonInReno

-

I realize this post has a lot of dust on it, but it made me smile nonetheless - picturing Uwe and the Amish pedaling a 441 was worth the cost of admission! I’ve been involved in a number of off the grid houses - in some very rural places in the Rocky Mountains and Alaska it’s correct to simply say “houses” since the “off the grid” is normal. What comes to mind right away is that self produced electricity is becoming less expensive every year as the solar industry expands, improves, and second hand equipment is becoming readily available for pennies on the dollar. Unlike many things we’ve built into houses that have a known lifespan, it’s a crapshoot to know how long the solar panels and converters are going to hold up and much of the used stuff has many years left in them. An Electrican friend has some 10 and 20 year old panels that he says are undistinquishable from each other in performance or reliability. His big 110 volt inverters were sold with a 10 year expected lifespan - zero downtime in the 20 years he’s used them. For recreational, off the grid, and the sailing crowd I predict we’ll see similar lithium ion technology like that available in the professional grade hand-held brushless hand drills and other tools....a “universal” integrated removable battery/brushless motor with a very compact variable speed input adaptable to all sorts of power tools, lights and other things that have motors and traditionally were hard wired. Within construction, individual carpenters are collecting increasing numbers of cordless tools and even more batteries. You’d think since lithium ion batteries have so much more capacity we’d need less of them, but since they are used more often large battery collections are becoming the norm.

-

What should I look out for when buying a Durkopp 291?

DonInReno replied to MrBurns's topic in Leather Sewing Machines

Based on that alone I’d stay far away from this machine. Whatever justification you come up with for buying it should be put on hold until after you have a basic good stitching walking foot machine like a singer 111w155, Juki lu-562, or similar... -

Yes, you are correct! The day I read through the Sailrite website an image stuck in my head of a smooth presser foot, but I retraced my steps and it was for an unrelated machine. :-)

-

I ran across a case of Dyneema T150 that was mismarked as Kevlar and bought a spool to see how it sewed and whatnot. That started a pretty good afternoon reading up on super threads to see just who is actually using them and what the advantages are if any. There is a lot of misinformation with people simply repeating something they thought was credible, or misinterpreting some specification, or who knows what. I was surprised that Kevlar simply isn’t used in many high strength applications, which essentially left Dyneema, which is essentially identical to spectra. The best information came from a couple of reliable places - the heavy rigging industry which uses Dyneema ropes and straps, rock climbing industry which uses Dyneema in some load-rated straps, and the riggers making skydiving harnesses. Essentially the destructive tests done by all three industries showed negligible improvement in seam strength because the dyneema fibers cut into the non-dyneema fabric and/or webbing. It seems the best place for Dyneema thread is with Dyneema fabric and webbing. There is also the issue with the slickness of Dyneema - locking in the beginning and end of a seam. Boat people like Dyneema because the ropes are compact, resistant to cuts, strong and float. The rock climbing folks were excited when Dyneema came on the market with claims of abrasion resistance and high UV resistance, because some climbing hardware is attached semi permanently to some climbing routes. Destructive pull tests by a major equipment manufacturer showed the Dyneema straps exposed alongside Nylon and Polyester straps did no better retaining strength than the Nylon, and far worse than Polyester. Dyneema company literature currently states Dyneema is highly UV resistant only if it’s ordered with a UV coating applied during manufacturing. There was one thing worth the price of admission - I did come away with a new appreciation for the randomness of strength numbers published by manufacturers. If we were all to vote on the breaking strength of 138 weight bonded nylon we’d essentially repeat what we’ve read - somewhere between 20 and 25 lbs. A fresh spool from The Sewing Exchange breaks at 35 lbs on my scale. It’s not a certified scale, but it wouldn’t be off by more than a pound. I’m guessing manufacturers down rate thread strength for some reason, but it’s not the actual breaking strength. Kevlar breaking strengths are so all over the board it’s essentially a useless number - from no better than nylon to twice as strong! On the same scale the T150 Dyneema broke at about 45 lbs - not nearly as much as I expected. It sews fine on my machines without adjustment. It will dull normal scissors - definitely abrasion resistant! Braided Spectra is available in just about every good fishing store if anyone just has to try it. Im disappointed there wasn’t as much information on Kevlar. Edit: If you’re interested in just how slick and hard to knot Dyneema is just look at any big game fishing board and the great lengths they go to just to get a knot to hold.

-

If I were in your shoes and had to spend under $1,000 this is probably the route I’d try: Of course this is an old ad, but these machines pop up at times for very little money. They have agressive bottom feed only, but can handle thick thread and 1/2” of leather. There was a new head on eBay last year for something like $450 and that included shipping. Every company calls their version something unique, but ga5-1 will turn up a dozen “different” brands. If you search and get a good deal on one you’ll be able to use it as many years as you’d like and get your money out of it - essentially free - can’t get any cheaper than that.

-

Beginner Saddle Leather Sewing Machine

DonInReno replied to Oelschlagel's topic in Leather Sewing Machines

These three get talked about as if they are interchangeable, but the Artisan and Cobra have the same capacity (thickness) as the full size 4500/4000/class 4. What the cowboy 3200 does have is a lower price, so if you don’t need the extra capacity you’ll save $300-$500. The Artisan 3200 has a 12” arm and will sew a full 7/8”. Cobra class 3 has a 9” arm and sews 7/8”. Cowboy 3200 has a 10-1/2” arm and sews 1/2”. I have the Artisan 3200 and it runs beautifully, but the cowboy dealers are active, helpful, and have a great reputation for support that goes a long way if you have hiccups and need good advice to get out of a jam. Cobra may have support that’s just as good - others are better able to comment on that. Artisan isn’t talked about much - I’m not entirely sure what happened on the playground - who did what or said what to who, but someone was buttt hurt....maybe some slow weekend I’ll search the gap in the old threads between when everyone was saying great things about Artisan and now. :-) -

I’d also check every edge that the thread passes over for grooves or burs. The only part you apparently physically moved is the needle plate - I’d take it off and look closely at it as well as how the bobbin case interacts with it. Have you taken off the tension disks to look at their condition? Have you grabbed the thread coming out of the tension assembly and pulled out a few feet looking for changes? With the bobbin in the machine and fed up through the feed dog pull the lower thread to feel for binding on a number of bobbins. Cheap bobbins are famous for being inconsistent in almost all dimensions and I recently had to toss out a handful of new ones that would bind in the bobbin case. I hope you figure it out - it’s always fun solving a mystery!

-

That guy is just trying to get more views claiming he’s discovered something unique....nothing he claims is revolutionary, difficult or a conspiracy. Of course sewing machine dealers won’t encourage modifying a machine - somebody’s grand kid puts his fingers in the new pulley and guess who gets sued. There is no upside for a dealer to sell anything except what normally comes with a machine. I’m in favor of improving the performance of a machine if it’s done in a way that demonstrates good judgement and craftsmanship. If someone cobbles together an abortion I have no desire to be the good judgement police - to each his own. edit: A larger handwheel won’t affect timing, but it does make it more likely that a needle crash or jam will screw up the timing since there’s more torque being applied.

-

Unfortunately as others have said you’re sewing just over the max capabilities of the 211w155 and similar machines designed primarily for upholstery. It’s probably worth it to measure your items since 3/8” is doable with upholstery machines. In the used market the choices for larger machines (Cowboy 3200 range) are slim, but if you’re patient there are some deals to be had, but there are very few $1,000 setups - anything less than $1,500 would be a good deal.

-

The most common machines you’ll hear about are less expensive copies of the Juki TSC 441. Cowboy, Cobra, Artisan, Techsew, and half a dozen others have full-size copies and some with shorter arms and less capacity. Some are better made than others and the amount of support you’ll get with a new machine varies from none to a lot. Used machines aren’t common, but they do pop up every month or two - usually it’s more a matter of being lucky enough to be close to the seller since shipping these heavy machines is a pain. If you already sew on smaller machines, have a high tolerance for problem solving, and have some extra time, if needed, to sort out potential problems with a used machine you’ll find something almost new for under $2k. There is a lot written here about every version out there it’s just a little challenging to find it.

-

Can anyone recognise the model please

DonInReno replied to chrisash's topic in Leather Sewing Machines

Without looking at it in person who knows how well it was made - obviously not a consew. If it seemed well made then it’s something I’d pick up to go with my fake 31-15 lol -

Altering flat bed accessory for cylinder arm

DonInReno replied to Ceejay's topic in Leather Sewing Machines

It’s obviously a low cost table - better than nothing, but not worth saving. At my day job as a wood worker when something like this comes up I’ll use what you have as a template to massage into what you want. Cut it, fit it, add wood, remove wood, fix the attachment points....and definitely use it enough to know what else you’d want to change....make the second or third round of changes until the fit and function meet your expectations then duplicate it with new material. edit: Um, since you ordered the table for a different machine knowing it wouldn’t fit, but willing to adapt it what I said above can be disregarded. Good luck - just keep at it and you’ll figure it out. -

What machines are these and any worth getting?

DonInReno replied to myjtp's topic in Leather Sewing Machines

Not knowing anything else about them (not knowing if they even sew), this is what I’d value them at: 1...$50 2...$75 3...$150 4....$50 5...$75 6...$50 Since you already have a good flatbed machine there’s no advantage to getting any of these. -

New industrial sewing machine table, where to buy?

DonInReno replied to myjtp's topic in Leather Sewing Machines

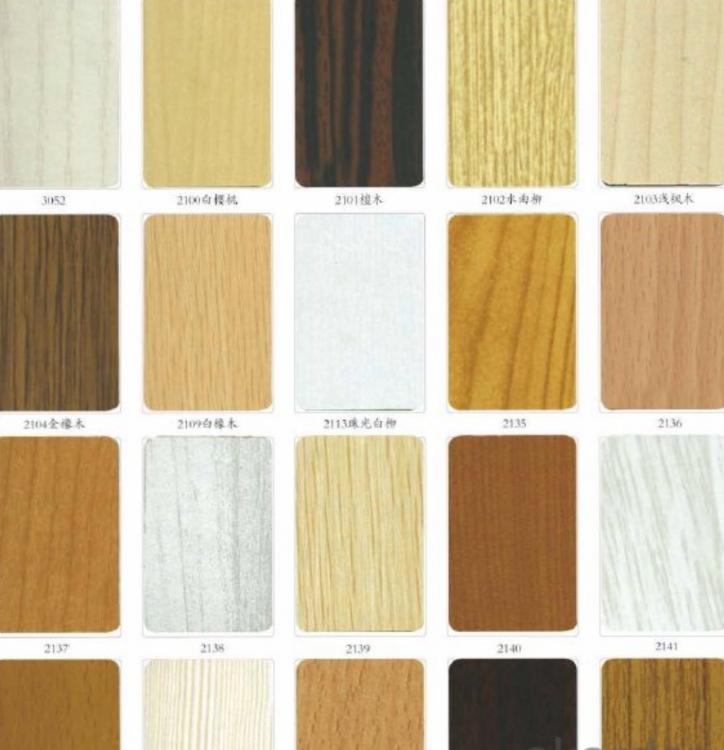

I’ll just add that if you really enjoy the basic look of a white high pressure laminate (HPL) top, which there is nothing wrong with, then one of the hospital white tops are pretty reasonable. However if you’d prefer a melamine top with more color - wood, patterns/colors, or granite look - then you might look into simply having the HPL surface of your table replaced. Formica is just one brand name, but there are many. One warning about online tables of unknown quality - the durability and thickness of the surface material is very hard to determine. Cheap tables will have less expensive brands and thinner HPL. Sewing is not as physical as football, but you definitely don’t want an edge to chip the first time scissors are dropped. Formica lists three thicknesses of many of their top - roughly .045” thick for normal flat surfaces, .035” for tops that have radiused edges as used in kitchen counter tops, and .025” for even tighter radiused edges. There are other even less desireable grades designed as liner material for areas not subject to much use, but must be covered by a water resistant material. If you have your table resurfaced the thickest version is what you want and liner material shouldn’t be used on anything. One of the best things you can do to stiffen a table is have the bottom laminated as well as the top - although few are. Anybody that installs laminate will have a lot of leftover scraps - there’s a good chance they would throw in some random piece for the bottom at a very low cost if not free. If someone tries to tell you a color is only available in a 4’x8’ sheet you might ask what they would charge for the installation if you supply the HPL. Many online sites allow you to buy partial sheets. If you want to try replacing it yourself there are many good videos online. Often the original glue will be heat sensitive and and old cloths iron can be used to heat and peal off the old top. Then use lacquer thinner and a putty knife to scrape any remaining adhesive off the surface. There’s usually no need to sand unless there’s a surface defect in the wood. The main catch to doing it yourself is getting the edge banding correct and developing a feel for how to cut the stuff without chipping. Definitely practice on scraps. HPL is crazy strong, stiff, and durable. Also some metal legs are thinner gauge metal than others - it’s worth comparing before ordering. Good luck whatever route you take! -

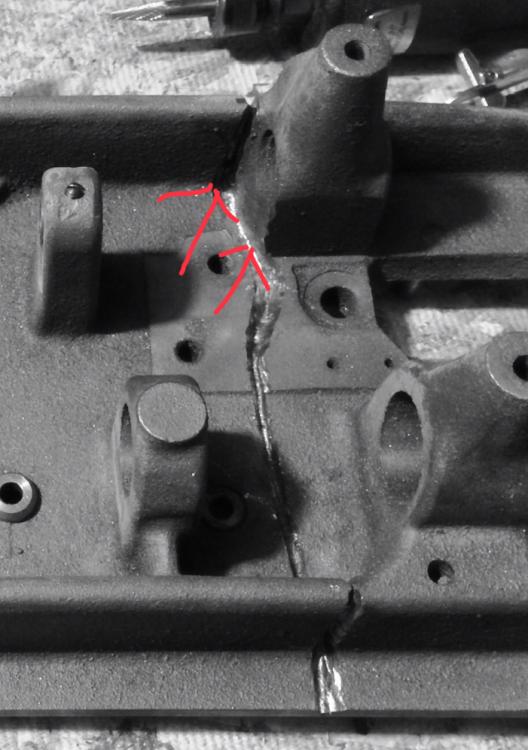

Until recently I’ve never spent much effort conserving heat on the backside and opposite end of a project, but a few well placed bunched up welding blankets made a huge difference in maintaining even temperatures. A good infrared thermometer has really been enlightening during preheat - at least for me it makes the difference between guessing and being within 200 degrees from one end to the other to simply taking a few measurements and easily being within 50 degrees. The next time I may prop the machine’s bed on its side to go a step further and allow torch access to the back.

-

Good deal? Cowboy CB 29 18” arm

DonInReno replied to WoodsHollowLeather's topic in Leather Sewing Machines

Very well said. -

Thanks Floyd. I’ve been interested in an oven for powder coating, but more uses keep popping up. Exactly - that’s a very good point. I ended up with a few pieces that were pretty straight and the bed clamped down quite flat, which was encouraging. However it was a rookie mistake on my part to clamp it dead flat and not allowing for shrinkage of the bronze under the bed. This morning a quick look with a straight edge showed a few unexpected irregularities in the top of the bed. The most obvious was due to shrinkage of the bronze - I’m thinking that can be corrected when I go back for round two to fix a few things. The second surprise was a slight bowing of the bed essentially from the front feet of the bed on back to the area of the crack - originally I had hoped it would be nearly flat other than where the crack was. If the bed were steel it would be easy to straighten with a torch, but I’m guessing that’s not an option with cast iron. This second go around I’ll try to get the joint at the crack a bit flatter then lap the entire bed flat so it looks decent.

-

Pfaff 138-6 Looking for price and parts help

DonInReno replied to Scoutmom103's topic in Leather Sewing Machines

Those deep scratches in front of the needle plate are strange. It’s also odd that one of the screws holding the needle plate isn’t flush. The tension unit nut is cross threaded and the hook is dull at best. I’m guessing someone ended up with it and they used poor judgement maintaining it until it quit working. If there is a 50/50 chance of it being an easy fix, and it’s worth $100 running, then in this condition it’s worth half of the $100. Those bizarre serrations in the bed reduce the value by half - I’d have no idea how to even explain them to a buyer - half of $100 is $50 so I’d have to agree with the others that as a fixer upper it’s not worth much. -

Thanks Dwight! Wow - I had no idea that’s what was going on in there!

-

I ran into something unexpected that relates back to your question. After grinding out most of the crack and clamping it to some thick pieces of 4” angle as the slight bend straightened the original crack in the web on either side closed up before the bed straightened completely - it was only about half way to straight. About .040” had to be removed - the webs were stretched a little before they gave out. That’s all useful information! In fact this morning just as I was about to start preheating the bed prior to brazing I noticed a faint line that wasn’t there the night before - apparently it was oil that had migrated down into the crack and some dust had collected on it overnight and in daylight it really stood out. I ground down another 1/16” to 1/8” to remove what was obviously more cracked material. The old advice to go slightly past the point where the crack stops and drill a hole to prevent further cracking makes sense to me now - the crack extends further into the material than can be seen by naked eye. I’ll almost bet the bed on my machine has micro cracks clear through it - if not from the original damage, from me clamping it straight while cold. After brazing this bed I’m definitely going to look into welding the next one. I have a cheap inverter dc tig setup and will probably upgrade to another TIG. It’s funny how the cost of nickel TIG wire is definitely less than the amount of gas I used today. I was out of propane for preheat and the #4 gas tip really took a long time and probably wasn’t large enough for the deep grove on the three sided inside corner (the pic showed the spot when I first started grinding, but the grove ended up being almost the entire thickeness of the bed and undercut the leg quite a bit. I was about to grind it out and TIG braze it while everything was still hot but the batteries in my auto dark helmet were weak enough to flash me so I said screw it, wrapped everything up and came inside. Lol For preheat I’ve always used a propane weed burner and have a couple of fiberglass welding blankets to wrap and conserve heat for post heat but a dedicated gas bbq would be nice especially to burn off oil and paint - I’ll keep an eye out for one!

-

Eric, I’ve always wondered what the variable speed mechanism is inside a zero max off a fabric puller?

-

The serial number is also funny - it’s a singer number for a model 39 made in 1910. At least to me it’s unique enough that it seems worth saving. I sprayed it down with lacquer thinner to take off some of the oily bits before setting it in an electrolysis rust removal bath, and normally a rinse with accitone or lacquer thinner doesn’t touch the paint much, but my gloves were covered in black goo! So it appears there were two top coats of slightly different green over a black coat that just melted off and under all that a gloss black coat that felt like normal cheap lacquer or dried out enamel - very thin and could be stripped off easily with a dull putty knife! Lol Its already mostly stripped of paint and an overnight soak should take off enough rust to free up the bottom side - the top side would move on its own, but it all has surface rust from being left outside for a while. I’ll give it a proper gloss black and probably use regular singer decals. I also have a 1920ish Singer 31-20 and the machining is nothing to write home about. What a surprise when under the paint of the Dinger 31-15 the cast iron was mostly smooth - really smooth - like smooth enough that you could put a super thin coat of paint on it and it wouldn’t look rough! Whatever part of the world this came from had labor that was cheaper than paint to put that much attention into cast iron. The areas that normally show machining marks were also better than my 31-20 so their equipment and skill weren’t bad. Now I’m no treadle expert of any kind, but now it’s obvious the back should say “SINGER” and instead says “SEWING”. In the back of the casting the letters look welded to the frame, but I don’t know yet if they were welded onto the foundry mould or attached after the frame was cast. It’s in the style of the harder to find industrial treadle and the mould used at the foundry does look similar to the Singers with the washed out emblem, not the more distinct one with more bold features and much more clear text. I’m not really into old treadles and don’t know anything more than that. It has a half dozen cracks that I’ll braze, the missing treadle pulley will get sourced from some kind of Singer, and the whole thing will get proper paint. I’m not even sure what kind of top old treadles used, but I have some left over 8/4” white oak that should look ok with a mission oak style finish. Now that I’ve spent an hour or so with it, the color and feel of the paint reminds me of the counterfeit stuff you’d see in Mexico and South America. It’s strange that there are no paint chips on any paint layer from pin cushions on the upper, nor chips from scissors, yet it was repainted 3 times and it’s been used a bit. Totally off the subject, but I just found an easy way to take high resolution pics and reduce the file size for posting on leatherworker! Simply open the picture and take a screen shot - at least on my iPhone 5s a screenshot is sized about 50k! Lol

-

Nice!

-

I’m sure the machine could have had a brace of one kind or another and worked fine, although it would have always bugged me. I’ve been enjoying welding and machinist videos lately, especially the cast iron stuff, and for the most part I’m hoping to get somewhat proficient at cast iron repairs since it pops up again and again in old equipment of all kinds. Eventually I’d like to weld some cast iron with nickel rod, but for now I’m focused on tig and gas brazing.