-

Posts

569 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by wizard of tragacanth

-

Shower curtain... what a great idea! One may be able to find a shower curtain with an interesting design. It would be waterproof and the proper thickness as well. In the U.S. we call these Dopp kits. If you buy one at the store, it will be lined with vinyl. Mine is lined with solid yellow but you could be creative. nick

-

Great idea!

-

If you have the real gun, why not use the real gun? I do this frequently, especially if I am only making a one-off. However, you could make an unlimited number of holsters from the same gun, if you wanted to. It's not going to harm it. I just wrap the gun in a single layer of Saran wrap and wet mold by hand (or in a vacuum bag), NOT in a shop press. nick

-

Start with Tandy tools but avoid the cheap versions. For example, Tandy has two different rotary punches (I am not saying that you even want one of these right now, this is just an example). The $18 one is made of stamped steel. You might get enough work out of it for one project but the holes may be sloppy! The $50 Craftool Pro version is expensive but it is a good tool and worth the money You may be able to find the same heavy, metal version on Amazon for less. It is worth a look. A slot punch is another example. The $13 cheap shiny silver punch that looks like chrome, is a poor tool. The $40, Craftool Heavy Duty Oblong punch, would be the level that you would be looking for. You will need a cutting mat or board. Cheap kitchen, poly cutting boards will work for this, or a poundo board from Tandy. You need cutting tools. You can start with a an x-acto knife for small projects and a utility knife for big stuff. If you are stamping, you will need a granite (or similar) slab to back up your work. You need the appropriate sized needles and thread for the particular project. You need a way to mark your stitching holes and a way to make the holes. You will need some dye. I recommend Fiebing's Pro Dye. You need a finish coat. As an example, use Satin Shene for a low gloss or Resolene for a high gloss. That's just two out of many available finishes. The list goes on, but I am getting tired. Watch some YT videos on the types of projects that you want to make and pay attention to the tools that they use. Have fun! nick

-

Saddle Scabbard

wizard of tragacanth replied to Josh Ashman's topic in Saddle and Tack Accessory Items

Ohhhh, Buddy! -

Cargo pants bag

wizard of tragacanth replied to Frodo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Frodo... wow, what a wild idea! You think up some cool stuff. nick -

6th holster

wizard of tragacanth replied to GnewVFL's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Oh, I really like this one! The contrasting red belt loop with your maker's mark is a great touch. Only the owner will see it but it really adds to the custom feel. nick -

5th holster

wizard of tragacanth replied to GnewVFL's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Grant, that is some cool artwork there! nick -

Beginner needing advice purchased item's

wizard of tragacanth replied to SDP's topic in Getting Started

Important question -- What are you planning on making? Off-hand, I am guessing that you will want to return all of this stuff and start over. Well, I take that back. You will probably want the edge beveler and if you have a drill or something similar to mount the slicker on, keep that, I guess. Again, there is no definitive answer until we know what you are making. nick -

How do I recreate this type of leather?

wizard of tragacanth replied to LostInThought's topic in How Do I Do That?

Yeah, I would agree, that is my first thought anyway. Without seeing it in person, I am guessing it is two layers of relatively thin leather, with odd shaped scraps of leather glued in between and lightly wet molded. Then maybe it is tied in a knot and left to dry! nick -

How wuhdja know ?

wizard of tragacanth replied to JLSleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yeah, I always thought that the only variation in the models was in the finish and the grips, I mean, a P238 is a P238 as far as I know. They don't come in different calibers or anything. I cannot imagine where or why they would differ. https://www.sigsauer.com/products/firearms/pistols/p238/ nick -

That's a nice looking combo. The holster matches the gun. Love those Wiley Clapp editions! I agree with JLS that I would go with a heavier leather, like 8/9/10 oz leather for a gun of this size and weight. It appears the the back panel of leather impinges on one's ability to get a full firing grip on the handle. The front panel looks just fine, in that regard. I would suggest trimming out that little triangular piece that can be seen peeking out by the trigger guard, when the holster is viewed from the front. This may be of no importance to you and I am talking purely about aesthetics here, but it looks like the belt slots could be cleaned up a little. I can see a little bump in the transition between the punched holes and where the slot was cut out. Wrap some 150 grit sandpaper around a paint stir stick or similarly flat tool, and smooth those out, then dye and burnish the slots. Not necessary at all however. nick

-

Rifle scabbard

wizard of tragacanth replied to Madmax500000's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice work. Your customer is going to be very happy and proud of this case. nick -

Ideas for upholstery leather?

wizard of tragacanth replied to zuludog's topic in Leatherwork Conversation

You could use it for lining jewelry boxes, valet trays or some such thing. Wrap tool handles? nick -

My local Tandy has a new display of several different machines. They have a hot foil stamper, a clicker press and a couple of others. They are definitely upgrading their own products, such as their Craftool Pro tools and incorporating desirable products from well know manufacturers. Several months ago, they gave me a survey for my likes and dislikes, regarding their inventory, things that I would like to see added to their inventory, etc. They are doing everything that they can to stay competitive. I applaud their efforts. I think we are seeing the beginning of a new and better Tandy. nick

-

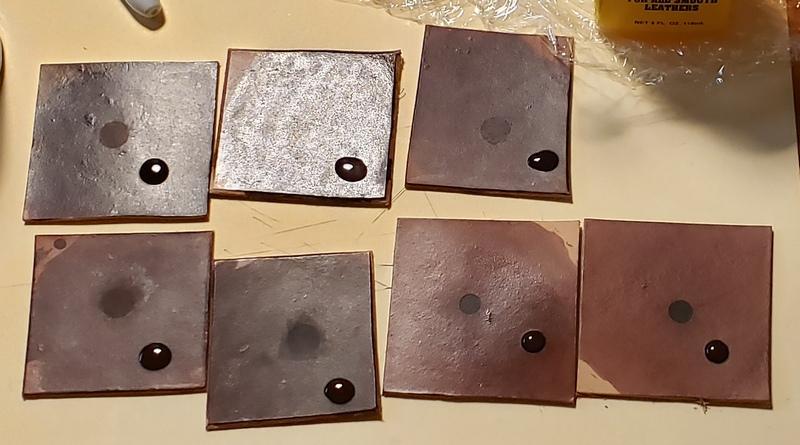

I was also very surprised by the results with Sno Seal and Shoe Polish, but as I said, I did only one application and did not warm the leather. In the next day or two, I am will do a second coat on all of them and re-test. The results could change significantly. Maybe this time, I will remember to put a Control Sample in the test, especially for color comparison. nick

-

Edge Bevelers: Barry King vs. Ron's

wizard of tragacanth replied to jdwhitak's topic in Leather Tools

Thanks zuludog. I think that I will go over to Tandy and see if they have a Pro Classic that I can try in the store. nick -

Yesterday, I tested seven different finishes. These were applied over Fiebing’s Pro Mahogany. I was looking for: color change, level of gloss, flesh burnishing and waterproofing qualities. This report is not super organized and may contain errors but I think it conveys the basic results of my tests. I do not wish to spend more time to perfect it because it was a casual test anyway. I put two drops of water on each sample. After one minute, I wiped off one drop of water and let the other sit until it was completely absorbed (over an hour or two). I wanted to know the short term and long term water resistance of these products. When the samples were completely dry, I buffed them in attempt to “repair” them as much as possible, without re-treating them. Buffing did slightly improve their appearance. The damage actually came in the form of cratering. It appeared that the solution had evaporated completely off of the sample. The edge was easy to see and feel. The crater was approximately 1/20 of a millimeter deep. Resolene won the water test. It was completely waterproof. I had a thick coat on there. The color change was quite dramatic but Tan Kote was even more so. Tan Kote was second best. The one minute test showed damage only if the light was reflected off of it in just the right angle. The long term test was a little bit easier to detect but not too bad. Tan Kote resulted in the deepest color change. Shocking, actually. Very dark brown. Satin Shene was a surprising third. The short test did show a very slight discoloration and some loss in gloss. You could tell there was some damage but it was minimal. Color change was very significant. Gum Tragacanth and Tokonole were tied. More damage on both areas than Satin Shene. Sno Seal and Shoe Polish were by far the worst. I must qualify this by saying that I did not warm the leather, nor use multiple coats. I smeared on one coat, rubbed it in and buffed it off. The water damage on these looked like they had burned with a cigarette or like acid had eaten into them. Satin Shene, Tokonole and Gum Tragacanth were the easiest to work with and they all resulted in a very similar semi-gloss finish. Resolene and Tan Kote were sticky and impossible to apply smoothly with a dauber. An air brush would be a much better method of application for these two products. BTW, I did not thin them for this test. I know that is protocol but I am lazy. Both have superior water resistance to the other products tested. Tan Kote can be applied with a dauber and then quickly spread with a finger to smooth it out. This actually resulted in a nice smooth finish that was second in gloss to Resolene, and significantly glossier than the others. If for some odd reason, I could only have one product for flesh burnishing and top coat, Satin Shene, Tokonole and Gum Tragacanth would all work but I would go with Satin Shene, because it had slightly better short term water resistance and it was the best of all the products for burnishing the flesh side. I do not consider this testing to be definitive in any way as it was not scientific and I may get different results if done on different leather on a different day. nick Top row: Tan Kote, Resolene, Tokonole Bottom row: Gum Tragacanth, Satin Shene, Neutral Shoe Polish, Sno Seal

-

Well, I have never done this but I think that soaking the piece in very warm water would be the best first effort. Hot as you can stand it on your bare hands. Let the leather soak until it is well saturated and the glue has had time to warm up. Then try to pry it apart with a butter knife or some dull edged tool. nick

-

Edge Bevelers: Barry King vs. Ron's

wizard of tragacanth replied to jdwhitak's topic in Leather Tools

I use a Tandy #2. It seemed to perform well enough. I got suckered into buying a Horseshoe Brand by one of Nigel's videos. I got a #1 Horseshoe, which is a close equivalent to the Tandy #2. The Horseshoe would make marks on the top grain when used on inside curves. Went back to the Tandy. What performance difference should I expect with a premium edger? I appreciate quality tools when they provide a qualitative difference. I mean... in the end, I just going to sand over it all anyway, right? Vikefan -- which Tandy edger makes a round profile? I am not familiar with it. Didn't know they made such a thing. Sounds like an actual improvement over what I have. nick