MakerUnknown

Members-

Posts

145 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by MakerUnknown

-

I found it, I forgot it, I lost it, and then found it again.

MakerUnknown replied to bikermutt07's topic in How Do I Do That?

Points given as well to the Rockmount shirt he was wearing.- 20 replies

-

- make easy edges

- beveled edges

-

(and 2 more)

Tagged with:

-

I like the falcon sitting on the chair at the end too!

-

I find stabbing the awl into some wax makes all the difference. Night and day difference. I have some beeswax melted into a hole on the pony that makes it so easy to hit if the awl is getting sticky.

-

Yes, thank you for the write up. Very informative.

-

Denver Knife Show

MakerUnknown replied to Jack142's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That Zvonek knife must've cost a million dollars. Wow, how is that done without it being cost prohibitive? -

Really nice work. Your father must love them.

-

IMG_20170505_170346.jpg

MakerUnknown commented on Godfrey's gallery image in Gallery- Our Leatherwork

-

I find the small sharpened part on the end to be very valuable in pull cuts. Excellent excellent craftsmanship in the Leather Wrangler's knives I do bespoke furniture and pride myself on my hand skills which require the sharpest of tools. I've spent a lifetime sharpening chisels and plane blades but when I opened up the round knife I was humbled. It's a function of course on how thin the blade is but still, it's the only tool I own that scares me. Always uber respective when I handle it. Leather Wranglers

-

Tool questions: good, better & really good

MakerUnknown replied to Railrider1920's topic in Getting Started

Very nice response, immiketoo. -

Making a sharpening jig for skiving knives

MakerUnknown replied to SheltathaLore's topic in Leatherwork Conversation

Among a host of other ways I sharpen my tools, I bought into a system that a luthier, Brian Burns developed. His jig allows for extremely acute angles of sharpening. At last report, he now longer manufacturers the jig but has plans he provides to make your own out of plywood, I believe. http://www.lessonsinlutherie.com/doublebevelsharpening.html -

Nicely done. Can't find it, make it.

-

Whoop! Whoop!

-

I would think the future of makers stamps lie in 3D printers. My real job is a freelance commercial photographer and have shot for this company for a few years now. They offer on demand prototyping using your files and printing on their machines. They can print using different materials, some softer or harder than others and as well as at different resolutions as in the quality of the printing. But I'm just a photographer and such I may know just a teeny tiny bit of knowledge on the subject. You'd have to figure out yourself how to go about preparing a file and figuring out what sort of material you would need. This is the company I shot for but there are others out there that might be closer to where you live. https://www.3dsystems.com/on-demand-manufacturing

-

I like how that bottom compartment is hinged...very cool.

- 10 replies

-

I too, live close enough to go in and buy. It's a wonderful experience. You walk in and keep walking into the warehouse portion. You can rifle through the pallets and pallets and pallets of leather picking out what you want. They encourage this approach. I know it doesn't answer the OP directly but they do two big buildings stacked to the ceiling and a huge shipping dept. so a lot of leather is leaving the place.

-

Hella cool!

-

Whoah! Movie set!

-

Field notes cover

MakerUnknown replied to Fire88's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Nice...I've kept a Field Notes in my front pocket for years. Just so handy to jot down thoughts as they pop in. I go to the Coudal website everyday and started to buy right when they came out with their Field Notes. -

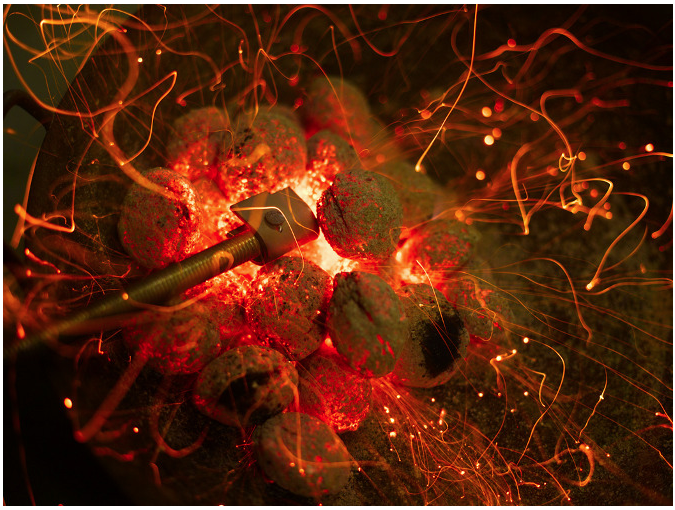

I heat my iron and press it down on the dry leather. Not much to it. These pics I did mainly for the photo. I don't heat the iron in a fire, just with a propane torch, and I don't do it with the amount shown in the photos.

-

Time to replace the Shetland Pony/Foal

MakerUnknown replied to Sledzep01's topic in Leatherwork Conversation

T-Boner? -

Time to replace the Shetland Pony/Foal

MakerUnknown replied to Sledzep01's topic in Leatherwork Conversation

Been thinking that maybe 4' might be a bit much. The clamping stick would need to be in quite a bit of tension which would necessitate a certain thickness which might make the force necessary to open up the clamp too much from an efficiency standpoint. But what the hey, won't know til you try. -

Time to replace the Shetland Pony/Foal

MakerUnknown replied to Sledzep01's topic in Leatherwork Conversation

4'? I don't see why not but you would need a large distance away from that for the "go bars". It's a very old method of clamping, using something under tension to apply force. They're used in framing walls on a house to not only position the wall vertically but if you need to pull or push the middle sections. Go Bars sold here to be used here in luthier applications. Which material you use would be an experiment for you. Something rigid enough but flexible..Sounds like a Zen koan. -

You, you and you! I love it.

-

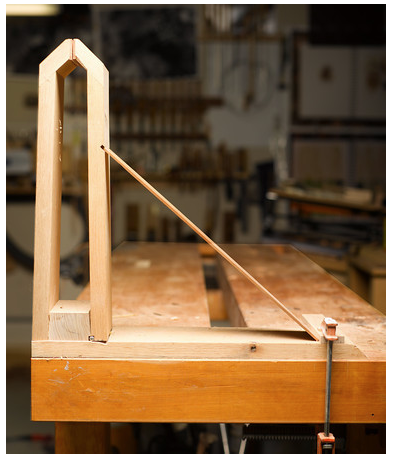

Time to replace the Shetland Pony/Foal

MakerUnknown replied to Sledzep01's topic in Leatherwork Conversation

Ha! Hadn't thought of a cat. But yes. I pulled this out of another thread on the subject awhile back. Although I don't think this is finished, this is how I built mine and use it. I wanted to accomplish a couple things with the design. I didn't want something running through the body of the horse as the method of clamping. I think a bolt running inside the horse would get in the way if you needed to clamp a longer piece. I didn't want objects on the outside of the horse that would catch the loops of thread while sewing. And I wanted a quick way of applying pressure and releasing the pressure in order to move the piece. So what I came up with is this. A thin flexible piece of wood that exerts the side force by being in tension. It works. There's a wide range of thickness it will accommodate within it's range. I lift up to release pressure, move the leather, release the thin board and the pressure is right back on it. I clamp the whole horse to my workbench and work standing up. I don't own a TV and have no need to sit and watch something while I'm stitching....it's better for you anyway to stand. So far loops of thread run on it without catching onto anything. I say it's not finished because I want to come up with a system that I can change the anchoring point for the lower part of the thin flexible wood quickly without needing a clamp.