-

Posts

3,794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by YinTx

-

Those rock! Now I hafta do one... YinTx

-

My first Shoulder bag

YinTx replied to Efe's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

That is awesome! I really like the red surround, and that is a lot of detail work on the characters! YinTx -

Unapoligetically color blind.

YinTx replied to sonnyboone's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Really nice work. Is that Teju? I can imagine it matching some of the more audacious watch faces out there... YinTx -

Ok, laptop seems functional again. Here are the images as promised. Again, not as great as Danne's but adequate for a prototype item. YinTx

- 13 replies

-

- fenice

- edge paint

-

(and 1 more)

Tagged with:

-

@Wizcrafts, @Uwe and or @Constabulary may be able to help. Also consider posting in the sewing machines section with a bit more descriptive title including machine type and issue, you may get a better response! best of luck. YinTx

-

Finished up, with adequate results. will post photos when I have a functional computer. YinTx

- 13 replies

-

- fenice

- edge paint

-

(and 1 more)

Tagged with:

-

Small bit of Sedgwick bridle needed!!!

YinTx replied to Travllin Leather's topic in How Do I Do That?

Traditional or modern? Also, what weight? I have some, depending on all that. YinTx -

Nice work! YinTx

-

Sorry for the delay, my laptop decided to go kaputz, doing this on a borrowed computer. Skiver and I have a tumultuous relationship at best. I have been able to skive with it, but did have difficulty when I tried it on gator. I'll try it with the sanding on the sides I want to skive. The gator I have is a pretty level 2 oz. I'll send you the new dimensions I've come up with. Also, stitches are out, on a positive note! YinTx

-

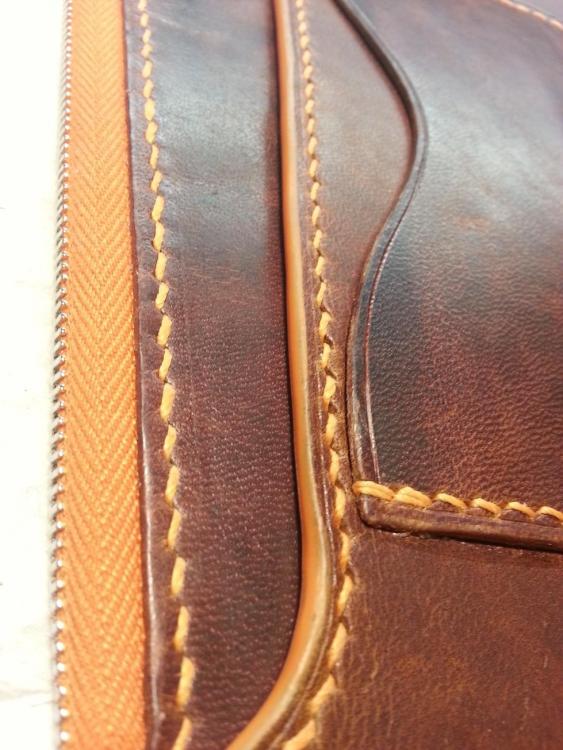

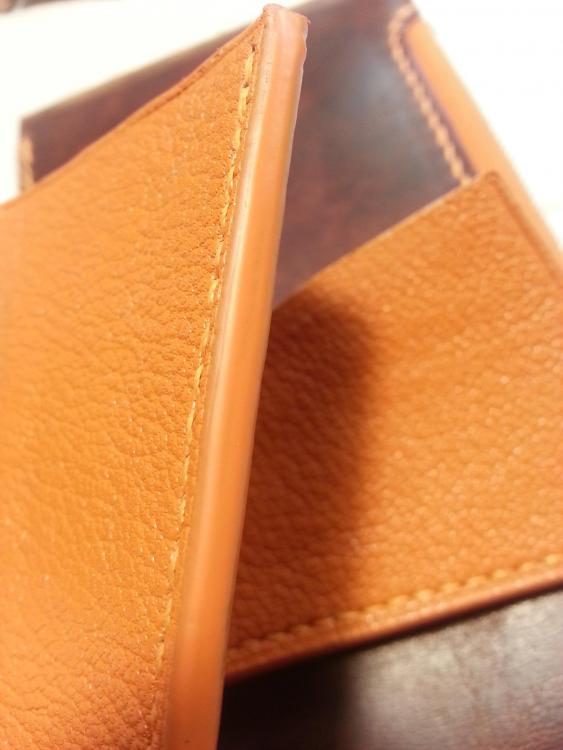

I am currently using Fenice edge paint on a very waxy Horween Dublin lined with Chevre Chagrin. Barge cement is useless to give you an idea of how waxy it is. I'll post the results when I am done. The project is a prototype, so I won't be going after the flawless edge that @Danne has achieved. I have only just applied the first layer, and letting it dry. YinTx

- 13 replies

-

- fenice

- edge paint

-

(and 1 more)

Tagged with:

-

Thanks for the detailed explanation on cutting into the hide. This will definitely save me some heartache and heartburn! I will take you up on your offer. As mentioned, my dimensions were too large, so I have to go back to the drawing board. Also, everything is all of a suddenly going slower on account of several stitches in my right hand, so bear with me. I'll have to make a new form block as well for the new size. YinTx

-

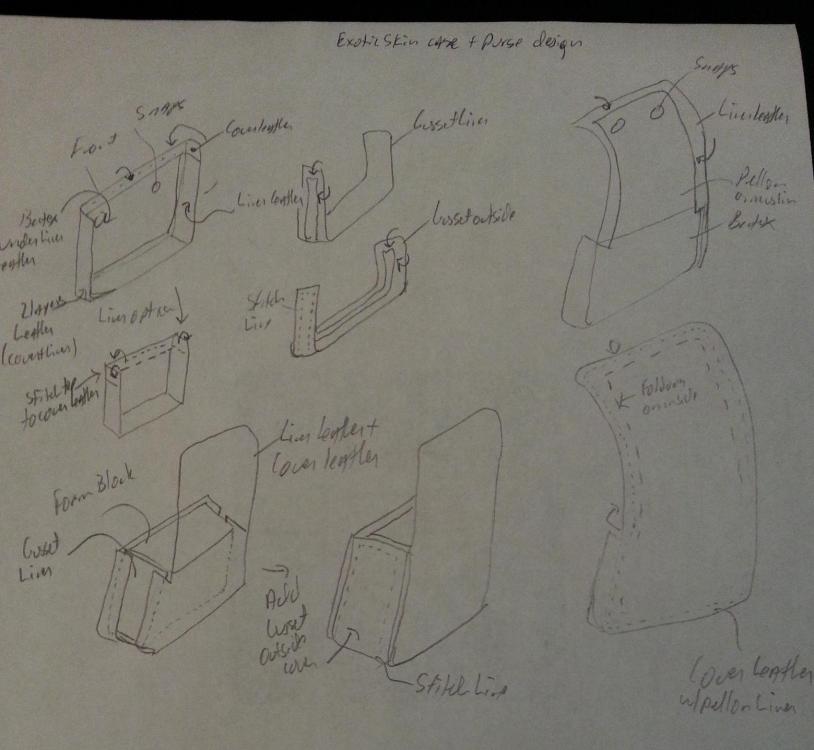

@RockyAussie, thanks so much for the info. Here is the design sketch I came up with. Lots of parts and pieces for such a little thing. I think twelve, not including snaps. I ended up using bag stiffener, about 1/16 inch thick, for the front and lower back pieces. Pellon (1/16") on the back and outer gusset piece, the inner lining and other bits were lined with fabric only to give me something to work up on to maintain dimensions. I had challenges at the transition between the lid flap and the body trying to not show any raw edges, which seems near to impossible since I have never seen it done. This is the form I made to shape it on. And this hapless fellow is slated to become fashion articles, so I can cut it in any direction needed. On the black and pink bag, I did not like the scales sticking up when the flap is closed, but I seem to have been the only one that noticed. I worried that cutting diagonally would be aesthetically unpleasing. Does no one notice that either? I had originally thought to use the tail, but if I read right, that may not be such a bright idea. YinTx

-

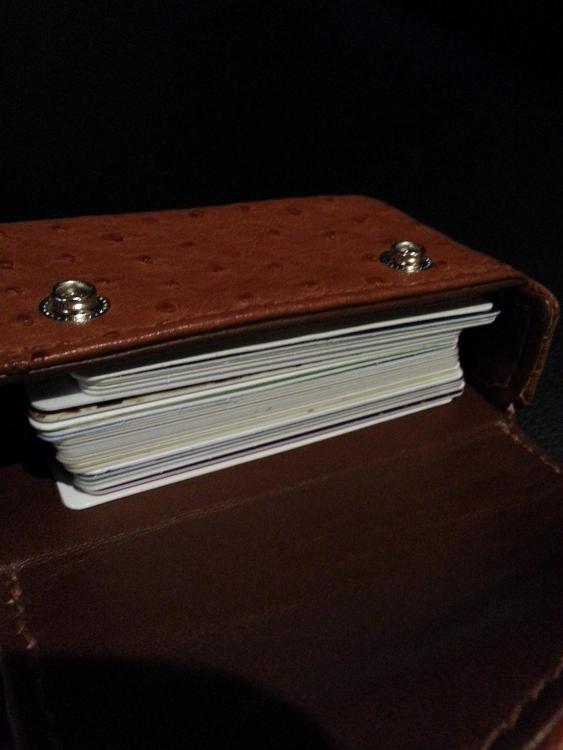

Version 4 of the case design. I think a bit oversized, very difficult to stitch together, particularly the gusset, which took nearly 6 hours. Of the 5 designs I prototyped, this is the one I liked the most. I am certainly open to constructive criticism, particularly on construction techniques, as the next one is to be made out of more expensive glazed Alligator. YinTx A couple more showing the inside, etc.

-

Axe and Sheath for presentation

YinTx replied to Woodshed's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Cool story and nice sheath! YinTx -

That bargrounding is impeccable! YinTx

-

Outstanding work! May I ask what weight leather you use for the tooled section? YinTx

-

I was starting to feel guilty about my knife collection, feeling a bit less so today. Very cool knives! Which ones do you like the most and least for which tasks? YinTx

- 6 replies

-

- knife

- japanese leather knife

-

(and 2 more)

Tagged with:

-

Agreed. If you click on the link provided, you will see it is not in English. You will also see that he is burnishing with gum trag, and thus you could deduce he was agreeing with that method, as opposed to just leaving it to burnish itself over time. @paloma has some great work, and has been trying to share his experience with us. Sadly, some does get lost in the translation, which is frustrating for him as well. Please be a bit more forgiving so that we can all learn from his efforts! YinTx

-

Nice work, that is a ton of tooling!! I have the same issue with black. Folks like my work, and want to know if I "have it in black." Like, "love the creativity, can you hide it so I can't see it now?" argh. "Love the hand stitching too, can you make it disappear into the black leather with some black thread instead?" YinTx

-

Pocket knife pouch sheath

YinTx replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Makes sense, pretty small for the belt! YinTx -

Ok, wait, I just noticed the coffee cup! That is fantastic!! The bag is still awesome too! YinTx

-

Pocket knife pouch sheath

YinTx replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Cool combination. Just curious, any issues with flexing the snakeskin backwards? also How do you put it on a belt? Or is it not for that? Nice work! YinTx