-

Posts

2,656 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Tugadude

-

Almost anything is better than nothing when you start. Buy the Tandy one, line it with leather as lapaglia wisely recommended, and try it out. If you stay with the craft, upgrade. Do you have a friend or relative that has tools? If so, it is pretty simple to build one when you are ready.

-

Yes, one is adjustable, but the other one rounds the edge of the leather as the stitching line is made.

-

When Prototypes Go Wrong....

Tugadude replied to thinckley's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I say fix it and either use yourself or if it is not saleable in the "fixed" condition, maybe give it to a friend. I bet it would be much appreciated. -

Been Looking For This Hardware Everywhere And Can't Find It

Tugadude replied to bylinesupplyco's topic in How Do I Do That?

-

Been Looking For This Hardware Everywhere And Can't Find It

Tugadude replied to bylinesupplyco's topic in How Do I Do That?

Ohio travel bag? They have tons of hardware, might have those. -

You pretty much summed it up and answered your own question. Adjust it so that your project doesn't move when you are stitching, but not so tight that you damage it. It is just a third hand, so to speak. No need to clamp down too hard. Did you line the inside surface of the jaws with leather? If not, that also helps.

-

http://www.leatherworker.net/Bob%20Park/Casing%20Leather.pdf Some good advice in this link. Especially with regard ro frequent re-wetting and how to maintain the casing for up to a week. Hope it helps!

- 6 replies

-

- oil

- conditioner

-

(and 1 more)

Tagged with:

-

Where are you located? Is there a Tandy near you? They have beginners classes. I see you found Springfield Leather, great folks there. There are tons of Youtube videos from which you can learn also. Books by Al Stohlman and others are great too. And feel free to ask questions here! We're all still learning.

-

Good luck with your new hobby. Nice looking belt. Lots of nice folks here to help teach and inspire.

-

- 2 comments

-

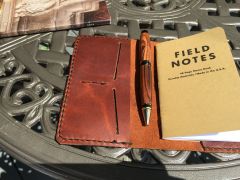

- field notes

- cover

-

(and 5 more)

Tagged with:

-

- 4 comments

-

- hand stitch

- hand

- (and 5 more)

-

- 4 comments

-

- hand stitch

- hand

- (and 5 more)

-

Your English is just fine and the flip flops are awesome. Great job!

-

What Is The Swivel In Rick Grimes Holster?

Tugadude replied to willlord's topic in How Do I Do That?

Not sure, but couldn't you use most any screw-on concho for that application?- 8 replies

-

- holster

- walking dead

-

(and 2 more)

Tagged with:

-

My First Wallet

Tugadude replied to JustinBrown8's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Don't worry about what style it is. It looks cool, is a fine first attempt and hopefully you will continue down the path! -

-

Now I'm wanting to stitch up a T-Rex bag, but I'm thinking my awl isn't sharp enough!

-

Springfield has single bends in buffalo that might suit your needs, check their website.

-

Mystery Braid Bracelets!

Tugadude replied to Grey Drakkon's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Stips would be easier with a cutting wheel and a straightedge. Use a straightedge with cork on the back to prevent slipping.- 32 replies

-

- mystery braidbracelet

- snaps

-

(and 3 more)

Tagged with:

-

In the photo above, the picture flips when you click on it, so black is on left. The black one is the Tandy. I get so confused! They both have Pro in the name, should have compared model #.