-

Posts

5,974 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by fredk

-

Mix beeswax and neats foot oil into a paste, as thick or thin as toothpaste, and apply liberally all over and after a while buff off the excess with a clean new shoe polish brush and some clean rags

-

Most excellent 1. US quart? a UK quart is more; 32 fld oz to 40 fld oz 2. What do you seal the insides with?

-

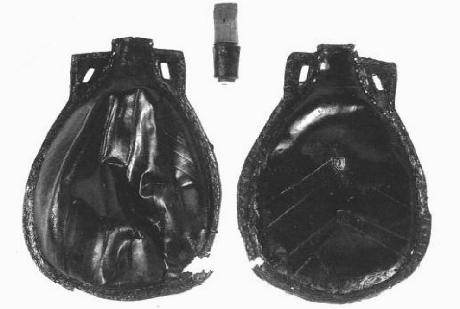

A leather bottle? yes? Over here a 'canteen' can mean many things, such as all the things needed to eat a dinner, eg cutlery, glasses, plates . . . . Ok. so I'm only teasing ya! But a leather water/wine flask type thingy. As long as you don't want to see it too soon I'll try making one. I've been wanting to make a sort-of copy of one from the ship Mary Rose The original; And someone else's reproduction of it; It involves some wet moulding, so I'll have to set to to make the buck but I'll not be doing it exactly as that other person did it

-

I believe 'Help for Heroes' charity is still going and although rather smaller than it was a few years ago I think it'll still be carrying on for some time. Its been a while but I/we (my club) gave them a load of plastic modelling things, eg, kits, tools, paints & glues et cetera HfH uses such hobby things for ex-service personnel to help them get over PTSD Contact; a, local police, b. Citizens Advice Centre, c local Military barracks - in any order, one of them is bound to know of a HfH unit near you. There are dozens located around the UK https://www.helpforheroes.org.uk/ You'll know when I've popped me clogs as my #1 son will be on LW selling my stuff.

-

A link to the Tandy punch https://www.tandyleather.world/products/pocket-notch-punch I just use an old 3/4 inch circle punch which was damaged and which I ground to a 1/2 circle then I round off the corners (sometimes) with a knife or scissors

-

I'll give you one reason - they aren't taught how to do it In the US, iirc, you have 'shop' in school where you learn woodwork and metal work. It is a rather intensive learning. Here in the UK we had 'wood work' classes which was no more than playtime with some pieces of wood. Nothing was taught, it was just a bit of school time in which time was wasted until the next class.

-

The really big down-side of buying internationally. Do let them know 1. how p***ed off you are with this and 2. that you've been discussing this on an international forum for both experienced and newbie leatherworkers and that their reputation has now dropped to below the Titanic

-

All the makers of these sorts of things seem to have their own non-standard thread In the past I've re-tapped the thread to match previously bought screws or bolts

-

Having been a postie a long time ago and received numerous injuries my extended sympathys are with your post-person. A cut from that blade could be very nasty. I'd be contacting the selling company and making a strong complaint. Looking for recompense, or replacement items. In the UK it is the seller's responsibility to ensure the goods get to the customer in good shape and fit for purpose. These items look and sound to me to be not fit for purpose. If you paid by credit card, usually the credit card company can take up the case. In the UK the CC will only look at items costing over £50 (last I knew) but anything over that and their insurance will get involved

-

The last time I bought a knife, a 'clicker' knife from Le Prevo, they put some thin foam sheet around the blade, then some cardboard around the whole knife, then some bubble wrap around that and used about a mile of parcel tape around the lot and then it was put into a thick plastic bag. The blade protection extended about 1 inch each side of the blade and about 2 to 3 inches beyond the tape. All this for a £4.50 knife! On a slightly different subject but similar; I bought some dye on-line. The seller sent the bottle loose in an oversized box. The cap was not 100% tight and there was no seal so a small amount leaked out. From another seller they sent the bottles with, on each, multiple layers of tape wrapped around the cap to bottle join, wrapped in newspaper, and in a self-sealing plastic bag and this all wrapped in bubble wrap and shredded paper in a box just about the right size for the bottle.

-

There is one version which is a rivet on. Like a ready rivet base and stem. Then you hammer, lightly, the post and ball of the Sam Brown stud. I had a few of them but I could never get them really tight. I think the screw base ones are better. Just cover the base part with a piece of very thin leather to keep it from scratching a knife blade edit to add; Tandy has the rivet type https://www.tandyleather.world/products/sam-browne-buttons-washers?_pos=1&_sid=25db6ec99&_ss=r

-

A peg board is real handy. I have all those other storage thingies too but I have different sized wood pegs on the back-board and its dead handy for putting something up on instead of losing it in the junk, er. . . . on going projects on that bench whilst working on things

-

yaaay! I can cut the first notch on my eco-friendly fly eliminator. I got one real good this evening. I have the blud-lust now, just need more victims

-

, but one fly a plague does not make. By the time I got my swatter it had got trapped on the sticky fly-paper

-

How is it a fly can find its way into room thru a 1/4 inch hole but can't find its way out thru a door hole 6ft by 3 ft?

-

In the meantime, you can use them to put your cup of coffee on, close to hand whilst sewing

-

Read the instructions. ~It usually says to put the 'polish' into 5 L of water and apply with a mop. And to remove, use ammonia diluted in water to about 5% and to remove after about 5 coats have been used BTW this stuff is far cheaper than Resolene. 4 US ounce, about 118ml, of Resolene costs me about £6. I can get the Astonish for about £1 for 750ml. I use it on everything except floors! ~ as a wood varnish, on deer antler, on my plastic models, to make PVA glue waterproof and quick drying

-

I've had moderate success* with a floor 'polish' called Astonish here. In the US it sometimes goes under the name 'Mop & Glo'. It used to be called 'Future', or 'Klear'. Its not a floor polish but actually a water thin acrylic varnish. I've been using it now for a few years instead of Resolene, both as a general sealer and as a resist. Results on leathers can vary, on some leathers there has been absolutely no change in colour, on some the leather darkens a bit *I have no long-time results to see how well it works, except maybe one; I used Astonish on some shield straps to seal the leather, for easier cleaning. The leather did not noticeably darken very much, just very, very slightly. After about 3 years of use the straps were still bright and light except for the soiling through use

-

Bette Midler? Lol

fredk replied to DustinSmith's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Wow-eee, that is so absolutely brilliant. Bette I instantly recognise, I don't know the other two but I guess you've caught their likeness very well too You appear to a have a talent for this -

It was 20 years ago this date terrorists attacked the US Homeland That date changed the World forever. We do not live with the constant fear of terrorist attacks but we are more vigilant to them Today, at some time, spare a thought, and if it pleases you raise a glass, to the memory of ALL INNOCENT people who have been murdered by terrorists, both before and since 9/11 and to those who put themselves daily on the front line of the war on terrorists, many of whom have paid the ultimate price John ch.15 vrs 13

-

Don't pay too much for the flexi curvy thingy. Its nothing more than a piece of rubberised plastic with wire inside it. A piece of heavy duty electrical cable does the same job Not used on leather work but on other things I have a set of French curves which are of more use

-

That is really a most impressive bit of craftsmanship

-

My 'leather' scissors are not the speciality type sold by leather suppliers but just very tough high quality scissors. They are by Mundial^. They cost me £12 each and I've ended up with 3 (don't ask). These scissors can cut through thin sheet metal as well. For curves I don't do anything fancy, I just grab a plate, a bowl, a lid, anything that has the right curve to it, or even just fold a bit of card in half and cut a curve by eye, trimming it to tidy it maybe*. Then draw around it. Using a pen to mark the leather gives me a more solid line to follow. Also, as I'm very colour blind I cannot actually see a scratch mark on leather * if I'm going to make more of the same item I keep that card pattern shape ^ similar https://www.amazon.co.uk/Mundial-2-inch-Red-Dressmaker-Shears/dp/B0009VEM54

-

I mark the curve on the flesh side with a ball-point ink pen then I cut the curve with my leather scissors. They'll cut at least up to 4mm nicely. If necessary a swipe or wee bit of sanding with a coarse grade sand piper tidies the cut