mike02130

Members-

Posts

513 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by mike02130

-

I use .5-.6 mm goatskin (chevre). I never worked with sheepskin but with soft leather I use a rotary knife. Instead of pulling the knife through, I first back cut the ending part closest to me a little bit then reach back and pull and cut. This way the end cut isn't stretched. When I glue two pieces of leather together I cut both oversized ,glue together then cut. In some circumstances, I have one piece the proper size and then make the other bigger, then glue and trim.

-

How do you deal with consistency in leather?

mike02130 replied to Piko's topic in Leatherwork Conversation

That's getting a bit thick, you may want to skive the edges. Pueblo is a soft stretchy leather. Do you have standard irons or diamond point or what? What size are they? Thread ought to be determined by hole size and distance. Buttero is nice leather for wallet making. -

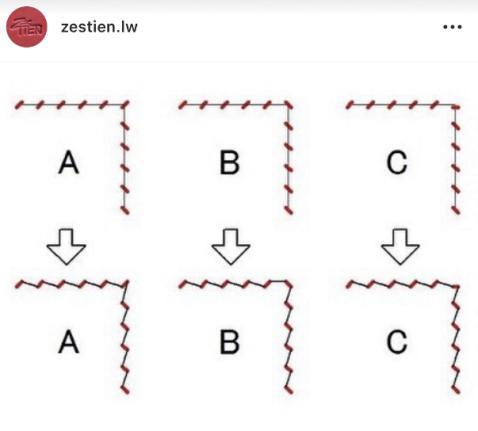

There is more than one way to saddle stitch. This is a common method and the one I use. When first learning I suggest that you pick one method and stick with it in order to avoid confusion. Flat work such as a wallet. Prick through finish side. Place in pony with finish side on right--the slants will be facing down and towards you. Start at far end. Count two holes forward and back stich (not explained here). Now you begin coming toward yourself. Poke right needle in to open up the hole and to guide the left needle. Pull out right needle as left needle enters. Pull thread a few inches. Place right needle below left needle, making a cross. Pull both sides of the left thread towards yourself (right and left side of the wallet) and insert right needle behind the left thread. Pull both threads through horizontally level (this causes less friction) and before the thread tightens, raise left arm up and away from you while placing right arm down and towards yourself while you cinch down the thread. Think of a cheerleader with pom-poms (keep your mind on the sewing, not the cheerleaders). Back stich two holes to finish off. The beginning and ending back stich will now match. Always be consistent in your movements. The stitching on the face will be slanted while the stitching on the backside will be straight. "Casting" will result in both sides having a slant.

-

I have a small snap anvil that is convex which will dome the backside. I bought it at Tandy years ago. Left domed right flat.

-

I caught my first fish with that brand 50 years ago.

-

How do you deal with consistency in leather?

mike02130 replied to Piko's topic in Leatherwork Conversation

I don't use pueblo much other than the occasional small item so I use my fingers and then wipe it off with a paper towel or rag. Wait awhile and then use the Saphir. It gives it a nice gloss. Pueblo is the only leather I do that with. I discovered this when I made a mistake and spilled some on the grain side and it left a spot. Tokonole has some wax in the formula. What do you plan on making and how thick is the leather? -

I concur

-

How do you deal with consistency in leather?

mike02130 replied to Piko's topic in Leatherwork Conversation

I don't know what you mean by finished. There is nothing you need to do to finish Pueblo. It has been dyed and buffed with what looks like an orbital sander. It has swirl marks. It has a matte finish. The edges can be burnished but I prefer edge paint. Tokonole works well on the edges but be careful getting it on the face of the leather, it may leave spots. Any conditioning on the grain side will darken it. I Tokonole all the grain then put a coat of Saphir wax. Looks better than leaving it matte and adds protection. Pueblo will patina faster than other leathers I've used. -

Oh okay, I thought this was some trick method to not pull a whole length of thread through the holes as you sew. But it has to do with the the thread around the eye of the needle from wearing out or the knot failing, right? Duh, I understand. I don't usually have any issue with the thread in the eye of the needle. I use poly thread less than .5mm in diameter. When threading the needle I pierce the thread 3 times and then go through the eye of the needle and then pull it tight like in Tugadudes picture. Occasionally the thread will come loose and if I catch it in time, I can just pull and tighten it up. After rereading everything, now I understand what Chrisash said about less pulling. But if I had a long tail, would that prevent me from casting? I'll experiment tomorrow. Thanks everyone for your help. I'm feeling kinda dumb, now.

-

Hmm, I don't get it. Say I have 6' of thread, I would pull say 4' (2' each needle) of thread that is hanging out the needle? If so, when I sew, the hanging thread would follow through the hole, wouldn't it? Obviously I don't understand.

-

Are all cheap strap cutters created equal?

mike02130 replied to BriarandThorne's topic in Getting Started

-

What is this long tail method? Thanks.

-

I use the 004 needles with #8 Vinymo. I use the same method as Tugadude's picture. I thread the needle then hold the thread between my thumb and fore finger then pierce the thread with the needle 3 times. I then scooch it up towards the eye and hold the two pieces and pull it up over the head of the needle. Hold the loop of thread at the needle and tug-a-bit (no relation to Tugadude) to tighten. Vinymo is unwaxed. Wax it first.

-

I believe that style is called an "English point". For an English point you can buy a punch or use a pair of wing dividers and lay it out on the belt end. Google it and check YouTube.

-

Pencil, paper and a ruler and dividers. Oh, and an eraser. I prefer a Pink Pearl eraser.

-

Nope, I never used a donut magnet. I did try others, though. The smallest donut hole magnet that you linked is one with a 1/2" donut hole. What sizes is the tool you want to use?

-

Goldstar sells dies and punches. The Amazon contraption gets good reviews from apartment dwellers and folks with new kids. An arbor press may be more trouble than it's worth. Even with a magnet, you would need to hold and guide the punch, hold the item being punched and with your third hand you would operate the press. There are some good YouTube videos on the subject. I have a Harbor Freight press and I tried to trick it out but it just didn't work well. There are other cheap presses that have a hole in the bottom of the ram for tools.

-

I've had this for five years and it works great. I've checked it with a feeler gauge and it stays accurate. Shipping included. https://www.rmleathersupply.com/collections/rulers-measuring/products/digital-leather-thickness-gauge

-

Alligators giving me headaches... scales peeling off.

mike02130 replied to scrapyarddog's topic in How Do I Do That?

https://jayhardtke.com/collections/alligator This guy knows everything about gator. I suggest you ask him. He's in Texas. -

I use .8mm leather.

-

You'll have to email them for a price. They're a whole lotta Krona. http://www.campbell-randall.com/public/index.php/shop/skiving-machines

-

We Americans are not used to the devil's metric system.

-

Mink, neatsfoot oils and tan kote are not suggested for aniline dyed leather. They will only change or ruin the color and are simply not necessary. Pre dyed leather from the tannery only needs wax. Saphir Medaille D'or 1925 Pate De Luxe Neutral Wax is probably the best wax. Feiblings makes a decent liquid wax. Bees wax is hard and sticky. It is best used on items such as sheaths, holsters and the like. Paraffin wax is easier to apply and has oils in it and will take a better polish. It's not necessary but I like to melt it in. I use an electric edge creaser to melt it into the edge. You could use a hot butter knife. Finish off with a piece of canvas or a rag from a pair of jeans. The Korba leather has a matte finish. It doesn't really patina but with use it gets more shiny. The flesh side may be smooth or fuzzy or both. The red is nice but the other colors are so so. Use Tokonole and a glass burnisher on the the backside. Rub a bit of the Saphir on the leather with your finger, let it dry for 15 minutes, overnight is better, then polish with a horse hair brush for best results. A bit of spit or a spritz of ice water helps.

-

https://www.rmleathersupply.com/collections/view-all-leather/products/luigi-carnevali-saba-reinforcement?variant=13981790175341

.thumb.jpg.2d2a47813d30216455b7b38eb1601fae.jpg)

.thumb.jpg.e006614ee4bc1762dc460994e524143a.jpg)