-

Posts

5,764 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Constabulary

-

Adler 167 - Timing Belt Replacement

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Excellent addition! Thanks for posting this! -

This is a very early Model 29 - not 29K the number is the serial number. You can check the date here: http://ismacs.net/singer_sewing_machine_company/serial-numbers/singer-no-prefix-serial-numbers.html Looks like 1893 made

-

you can also buy the slide piece new - from my experience they all have the same diameter - then its safe that the thread lever adjuster thread will fit. https://www.college-sewing.co.uk/82231-piston-joint-singer-29k-71.html

-

Check the manual, I´m sure it describes the function of the adjuster better than I could explain. However - very early 29 patchers came entirely without the lever adjuster and being honest I tried this adjuster (mine is different one but still) a few times and I have never ever noticed a significant difference in stitches or the position of thread knots - really - never! I only alter the top thread tension and that's it. It may depends on the material (thickens & density) you sew. That does not mean it is useless but honestly yet I haven´t noticed any difference. Other may have different experiences but this is mine. But when ever you will sell this machine - and this day will come - you still have an incomplete machine and a "knowing buyer" will notice this. So I would try to find this part just to have a complete machine.

-

is it probably because you are using a too small needle size - I´d try to go up 1 or 2 needle sizes. Edited 8 hours ago by Constabulary Forget this - I got you wrong

-

The above J & R is a maybe 100+ yrs old domestic sewing machine - not a leather sewing machine. Be careful - a Union Lock Stitch is not the same as a Union Special that is making a lock stitch! Also - "industrial" does not mean a thing when the seller does not know what he is talking about. You (as a potential buyer) should know better than a seller what you really need. Do not rely on what others are writing in their adverts or ebay listings. It´s better to know better - if you know what I mean. Start reading this thread - you will learn a lot about sewing machines:

-

I basically have restored all my sewing machines and if I would be a purist I would probably have a pile of cast iron but not many working sewing machines. You either buy what works / is available or you wait until you find a 2nd or 3rd machine to get together all the OEM parts. But yes, when ever possible I try to replace the "cheap parts" with OEM parts but that's not always possible. My 1st priority is that the machine is sewing the way I need it and then on the long view I try to find OEM parts (often enough randomly). I even have thrown out original parts and install foreign parts until the machine suits my needs (f.i. a needle bar just because I want to use a different needle system). Then OEM has no priority instead functionality is what counts. So it depends! But 1st priority is always that the machine does what I want - sewing! is it probably because you are using a too small needle size - I´d try to go up 1 or 2 needle sizes.

-

Have you tried to move the needle holder a bit closer to the hook? Also check the paddle shaped spring on the needle bar, sometimes they wear out and have a grove on the inside. When the leather is pulled up with the needle you need more foot pressure. What needle size and thread size are you using? Maybe you can try 135x16 needles because they have a scarf and can be set a bit closer to the hook. I`m also using 135x17 / 135x16 needle in my 29K71. Just what came to my mind... Please post pictures of your machine so maybe we can see something "unusual".

-

I also have a 108w20 - you can download parts list and user manual in the 1st post here:

-

this should not be a a serious problem and from my experience rather easy to solve. I don´t see why it should not work. "Far east" tension units are not as good as the OEM ones but you usually can make em work (maybe with exceptions). If i got it right the inner pin #11 is coming out a bit when you lift the foot lever, right? I would either try to make one tension unit out of two - parts should be interchangeable or put in a longer inner pin (#11) or a longer small "inside stud pin" (#25) or bend the silver "release plate" (#13) on the backside until it reaches the long inner pin (#11) or a combination of the mentioned options. Can´t be too difficult. This at least would be my way.

-

https://www.college-sewing.co.uk/418j-spring-stud-singer-29k.html Below stud is NN105H instead of NN105J but I don´t think it makes a diffrence https://www.college-sewing.co.uk/nn105h-113105-stud-nut-singer-29k.html Cannot find the two number but I think its the thread take up lever adjuster as it is missing in your picture https://www.college-sewing.co.uk/82166-thread-take-up-adj-assy-singer-29k.html If you figure your stitch length is rather short I´d order a Bell Crank Lever too. https://www.college-sewing.co.uk/82167-feed-motion-bell-crank-lever-singer-29k-412818.html Pretty sure you can get the parts maybe from Toledo Sewing Machines or Keystone Sewing or other industrial sewing machine dealers in the US.

-

Since you have another 30-70 I would try the hook from the other machine and see if it makes a difference. Well thats something we cannot solve online. I would apply heat and / or penetrating oil.

-

some pictures may be helpful

-

The 29K58 is very close to the 29K71 which is one of the latest models in the 29K series. Only differences I recall is the spring for the thread take up lever is attached with a plain screw whereas the 29K71 has a thumb nut and the 29K58 may come either with the new or old style thread take up lever regulator (I have seen both on a 29K58). Some 29K58 only have the hand wheel on the right end but I also have seen them with a front wheel (front wheel drive requires extra parts like gears, hub, shaft and so forth). However machine could have been upgraded with parts over the years - you never know. The front wheel machines often cost a bit more because they are a bit more flexible to use - depends on how you want to operate the machine. Confusing - yes it is! 29K´s came in a lot of variants / subclasses. Basically you can say the higher the subclass number the better the parts situation. The price depends on how badly you need a machine like this and if it suits your needs as well as the condition, the accessories it comes with (treadle stand or motor driven with industrial table, extra hooks, spare parts...) and of course the local market so I agree with kgg. EDIT: And most important - the stitch length matters. The more worn a 29K machine is the shorter becomes the stitch length. Even when set to the longest stitch it sometimes can be just ~ 3mm or even less. Usually the max. stitch length should range between 4.5 to 5 mm Stitch length when in technical good / very good condition. 5mm is rare on a used machine but can be achieved when you replace parts and machines is properly adjusted.

-

Singer 111w155 or Singer 111w154

Constabulary replied to Don Ayres's topic in Leather Sewing Machines

Seems to be from 1951. This chart originally came from Keystone Sewing Machine Co. if I recall correctly -

Dürkopp 18 Patcher Restoration - long journey...

Constabulary replied to Constabulary's topic in Leather Sewing Machines

I have to revise this - seems some Class 17 models actually came with this type of needle plate. I have learned something new! The class 17 came in some variants as it seems (probably even beside the sub classes). Unfortunately finding information on these models quite a challenge. -

lots of dead ends in God's evolution - some creatures even became leaders of certain states. Life can be so easy - isn´t that rather smart? But I understand your point - I for sure have a different perception cause I live on the other end of the world and do not have them around all day. We are "suffering" from other things here - it always depends on the location and perception. But mother nature seems to have the general view BTT

-

Have you thought about keeping just the machines head + accessories and buy new stands and motors in Canada? That would save weight and space and you still have the machines you are used to. If the 29K´s are old clunkers like 29K4 I would leave then in the UK if they are 29K60 - 29K72 (or something in between) I would keep them I guess. Techsew patchers are 29K7x clones like most of the Chinese patchers - I think they are as good / bad as any other Chinese 29K clone.

-

safe a Koala

-

Vintage pfaff 335G-h3 stitching problems

Constabulary replied to tibee's topic in Leather Sewing Machines

There is an arm cover plate which covers the feed dog driving rod or what ever it is called - the thing that moves back and forth and the feed dog is attached to. this is OEM for the 335 https://www.college-sewing.co.uk/91-014643-91-plate-pfaff-335 Or after market: https://www.ebay.de/itm/113842325012 or as a complete set: https://www.ebay.de/itm/113979423902 But check your prats list first, not sure about subclasses but I´m pretty confident that they will fit. -

Dürkopp 18 Patcher Restoration - long journey...

Constabulary replied to Constabulary's topic in Leather Sewing Machines

You have a Dürkopp Class 17 with a needle plate that most likely comes from a Singer 29K - Interesting modification! But from the pictures I cannot tell the subclass, But I think it is a small or medium size hook. I have no source for the bobbin winder or other parts - maybe LW Member SHOEPATCHER has something. I´m sure he will jump in here soon. -

Allbrook & Hashfield needles

Constabulary replied to John at Byson's topic in Leather Sewing Machines

Not sure how many different needles systems A & H had but these one took me 30 seconds to find: https://www.college-sewing.co.uk/allbrook-hashfield-pack-of-10-needles-size-25b-45.html https://www.college-sewing.co.uk/allbrook-hashfield-pack-of-10-needles-size-16b-80.html https://www.college-sewing.co.uk/allbrook-hashfield-pack-of-10-needles-size-14b-85.html -

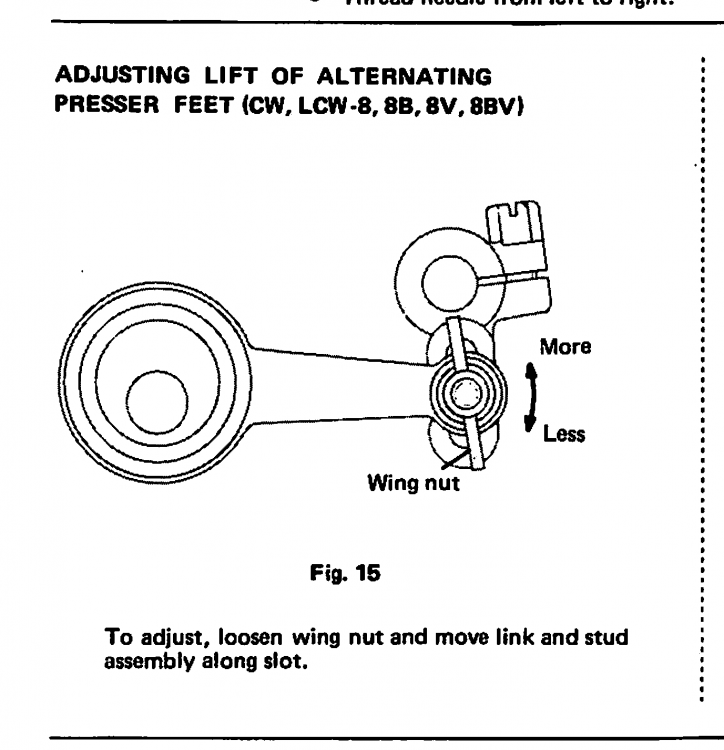

Good Lord - that does not sound healthy at all. I think the machine needs an oiling. What machines brand & model is this? With increasing foot lift I mean more foot lift while sewing (or should I say foot stroke?) - you can adjust this on a cam on the backside of the machine (at most models) - I guess you have a manual for your machine. It should be mentioned in it. EDIT: Like this - its from a Seiko manual EDIT II: inner foot seems to have more lift / stroke than the outer foot. Both should lift equally.

-

The pictures in the Seiko SK-8 Manual in the above linked thread are a lot clearer than in the Singer 132K Manual. I link it here again: https://leatherworker.net/forum/applications/core/interface/file/attachment.php?id=136658

-

Recommended Knee Lift for 206RB-1

Constabulary replied to Teslabolt's topic in Leather Sewing Machines

I would try a "singer type " knee lifter - they have a "flat push up" plate - I guess that one would work better. Or weld / solder a flat plate on the "push up stud" on your knee lifter https://www.ebay.com/itm/SINGER-KNEE-LIFTER-COMPLETE-ASSEMBLY-228368-FOR-111W-112W-107W-SEWING-MACHINES/400475096694

.jpg.03e0651860bde2166b792ed40f917442.jpg)