-

Posts

5,263 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dwight

-

Depending on the "look" you want, . . . either 277 or 346 should do right well there. Your veg tan is in the 6/7 ounce category, . . . which I use a lot, . . . and my sewing machine is set up for 346 thread, . . . all my customers are happy with it so far. May God bless, Dwight

-

Thanks, Steve, . . . I think I may have solved the problem, . . . but at the same time, . . . it is good to know you are out there. Are your stamps made of delrin or one of the other wonder plastics? Thanks, may God bless, Dwight

-

Kansan, . . . IFFFF, . . . I had my druthers, . . . a perfect piece of 6 oz works best for me. That makes a belt that is just over .180 thick. I'll go up to .240 for special belts, . . . but the usual, . . . standard, . . . I like to keep in the .165 to .200 area. It makes a good sturdy belt, . . . yet it is not super thick and fat. One thing you will want to avoid on belts that will be subject to loads, . . . never sew across the belt. What happens is the sewing becomes a perforation line, . . . and it makes your sewing line THE weak point of the belt. It's an old trick I picked up from harness, . . . harness makers never sewed across their straps, . . . and while I'll admit never losing a belt to this, . . . I just have made it a habit that I do not do it. May God bless, Dwight

-

Hey, Howard, . . . from one old sailor to another, . . . have fun with that. What kind of holster did you make? Post some pictures, . . . everyone here likes to see new ideas. May God bless, Dwight

-

Problem Customer That Makes Me Want To Scream.

Dwight replied to GaryNunn's topic in Leatherwork Conversation

I'm with ya Gary, . . . one bad customer can ruin your whole day. I'd just give him back his money, . . . toss the holster in a drawer, . . . sooner or later a buddy will need one, . . . he'll be tickled pink when you joke and tell him you need 59 cents for the hardware, . . . but he can have the holster for free. We've all been in your boat, . . . it ain't fun, . . . but with Ebay being what it is, . . . get your holster back, . . . give him his money back, . . . go on down the road. May God bless, Dwight -

Belt Clip Source

Dwight replied to steelhawk's topic in Gun Holsters, Rifle Slings and Knife Sheathes

You'll have to do a better job on the picture. When we click it, . . . it gets even smaller than the little one in the post. Cannot see what you are trying to portray. May God bless, Dwight -

Trooper, . . . is the class 4 a walking foot machine, . . . ?? Thanks, may God bless, Dwight

-

The only one problem I ever had, . . . used a blue gun full size 1911, . . . it was to be for an older Springfield stainless (Loaded???) 1911. The slide was definitely wider on the real gun, . . . messed up the whole thing. BUT, . . . that is THE ONLY problem I've ever had. YMMV May God bless, Dwight

-

Considering Getting Into Leatherworking And Looking For Advice.

Dwight replied to Hairic's topic in Getting Started

Quite honestly, . . . an hour spent at a Tandy Leather shop should be time well spent. You will have far more questions than you have offered here, . . . and they can answer them as fast as you can ask them. If you should happen to get a dufus salesperson, . . . come back later, . . . or find another store. Even if you have to drove 100 miles, . . . it should be worth it. May God bless, Dwight -

Yes, . . .you can, . . . if you handle it while it is still in case (damp). Let it fully, . . . FULLY, . . . dry, . . . my rule is a full 24 hours minimum, . . . before I handle anything serious that I have stamped. And then even, . . . I might drag my feet a bit. Like I said upstairs, . . . I'm not a really good leather stamper, . . . tooler, . . . whatever, . . . so I do my best not to mess up something that I've spent some serious time fixing. May God bless, Dwight

-

You can mold before or after dyeing, . . . OR, . . . you can use the dye to wet the leather for molding, . . . effectively turning two separate operations into one, . . . and saving time. I dip dye everything I do for the most part, . . . and even if I have already molded it, . . . I'll touch up the molding when I dye it. May God bless, Dwight

-

Looking For A Inside Waist Band Holster Pattern For A Sig Sp2022

Dwight replied to biglew's topic in Patterns and Templates

Biglew, . . . if you have not already seen this, . . . take a look, . . . this pancake is a bit different from the ones I make, . . . but look to be quite sturdy and useful. This is also an easy to make holster. http://leatherworker.net/forum/index.php?showtopic=68882&hl= May God bless, Dwight -

For that price, . . . I would be in the library, . . . borrowing the book. Sometimes if you bug the local librarian a couple or three times about a book, . . . they'll go get it for you. May God bless, Dwight

-

I always tool first, . . . (almost always anyway), . . . because if I'm gonna mess up anyplace seriously, . . . it'll be there. If I do, . . . I just toss it and start over, don't have a bunch of other labor involved...............yet. May God bless, Dwight

-

I got an order for a belt from a niece, . . . need a stamp as she would like to have "butterflies" on her belt. I am not good at carving something that intricate. Hoping somebody has a 1 inch butterfly stamp the'd part with for a reasonable fee, . . . It needs to look something like the picture. Thanks, may God bless, Dwight

-

Like ^^^^^^^^ he said ^^^^^^^^^^^^ pictures just don't show up............ May God bless, Dwight

-

Looking For A Inside Waist Band Holster Pattern For A Sig Sp2022

Dwight replied to biglew's topic in Patterns and Templates

Biglew, . . . I don't use clips, . . . I use a strap that is basically just a 3/4 inch wide piece of leather, . . . and it snaps onto the tip of the holster sides. May God bless, Dwight -

I've never done a really large piece like those purses and bags, . . . the small stuff I've done, . . . Weldwood contact cement has done me well. May God bless, Dwight

-

Did you get the PM? May God bless, Dwight

-

I take a ball point pen and outline my piece, . . . then take a razor knife (that has been previously stropped SHARPPPPP), . . . and cut away at the pattern. Since almost everything I do will have the edges sanded anyway, . . . I can get away with a less than perfect cut, . . . and the beveling always removes any extraneous ball point pen ink, . . . it works for me. I used to use a pencil, . . . gave it up, . . . sometimes I would follow a shadow, crease, or something, . . . got out the ball point, . . . works every time. The only real exception to the above is when I grab the old strap cutter and start in with it. May God bless, Dwight

-

When I took mine in to Ben, . . . before he took the back off, . . . he tried it "as is" and just shook his head. He looked at the bobbin, . . . the needle, . . . you know, . . . gave it the $ .25 onceover. When he couldn't find anything else wrong, . . . he flipped it around and took off the back. He actually had the guy working next to him come over and look , . . . asked if he had ever seen one slip like mine did, . . . it was like 2 1/2 or 3 inches to the right of where it should have been. He told me that the distance was just short of critical, . . . and while I couldn't remember what it was, . . . I went out and measured it, . . . from the inside edge of the casting, . . . to the nearest edge of the collar, . . . is 5/8 of an inch, . . . and he marked it for me. The marks you see to the right of the collar most likely are knurlings on the shaft, . . . mine has them too. It's pretty difficult to tell in the picture, . . . but like I said, . . . mine is 5/8 of an inch, . . . and works flawlessly if I do my part. Best wishes, my friend. May God bless, Dwight

-

Once you have the piece cut out for the front and the back, . . . lay it down and trace the back, . . . round cut the top of it like in the first picture you posted, . . . then punch and cut the slots just like in that same picture. OR: What I'll do sometimes, . . . is to play with my computer, . . . take a picture and make it 10% bigger (or smaller, depending on what I need) until I get it exactly the size I need so I can lay it down on a piece of dampened leather, . . . trace the outline and details with a ball stylus, . . . remove the paper, . . . go to cutting leather. I've used up a dozen sheets of paper from time to time, . . . but it has none the less been well worth it to get EXACTLY what I needed. May God bless, Dwight

-

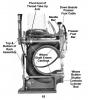

Mike probably gave you the answer, . . . BUT, . . . if that didn't do it: Refill the bobbin that did work, . . . and try it. If it works, . . . take a ball peen hammer to the one that did not work. Then you can toss it. Double check the needle, . . . they can be ever so slightly bent, . . . and NOT WORK AT ALL HARDLY, . . . UGH !! Last, . . . take the back off your machine, . . . make sure everything looks like this picture. Especially the upper left corner. That collar slipped on mine one time, . . . I wound up not seeing what was wrong, . . . took a day off from production, . . . drove 200 miles to the Tippmann factory, . . . Ben fixed it for me, . . . free gratis. May God bless, Dwight

-

I agree, . . . TinkerTailor has it nailed, . . . at least that is what I would do. May God bless, Dwight

-

I Made My First Gunrig!

Dwight replied to Dorado's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I like it, . . . but it makes my fingers hurt, . . . all that hand stitching........... Good job, . . . good perseverance. May God bless, Dwight