CowboyBob

Contributing Member-

Posts

3,312 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by CowboyBob

-

Yes,very well built & look like it'll do the job.

- 24 replies

-

- quick-release

- qick release

-

(and 1 more)

Tagged with:

-

Adjusting stitch length Singer 153W103 alternate method

CowboyBob replied to Lindy's topic in Leather Sewing Machines

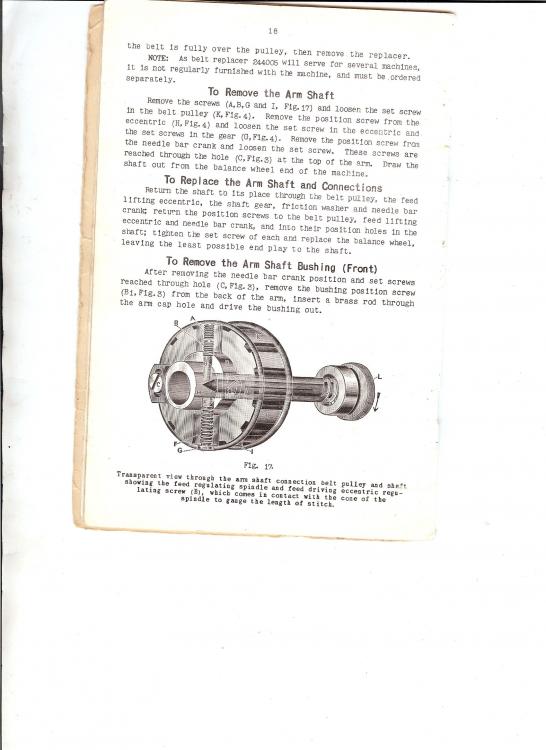

Here's a pic of it.Like Wiz says you don't want to loosen the larger screw w/a spring under it ,the smallers ones(A&B in diagram) are down in a hole(casting) Turning it to the left is smaller ,right is longer. -

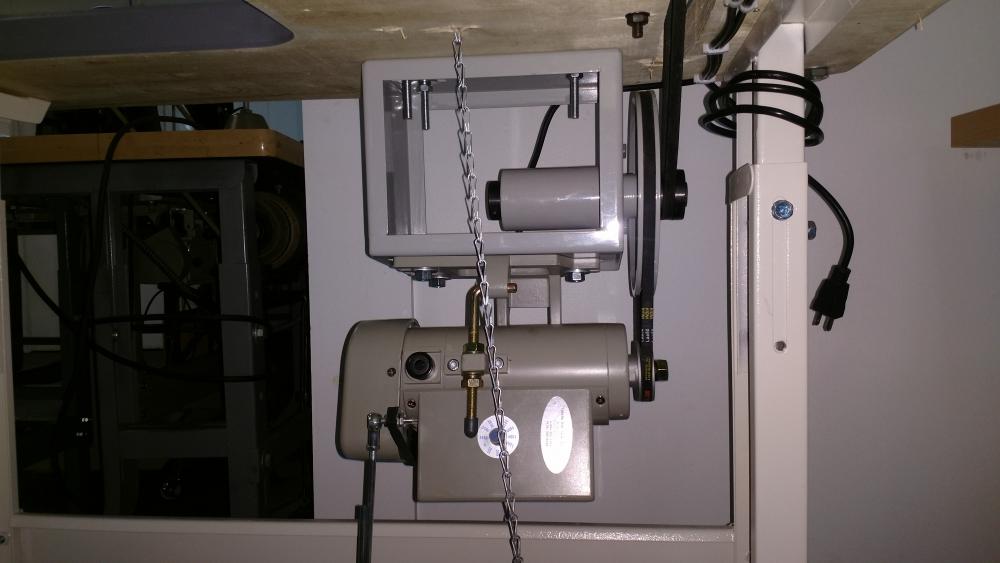

Yes,we are it sells for $190.00+ UPS. It give a 3-1 reduction same as the other type.

- 24 replies

-

- quick-release

- qick release

-

(and 1 more)

Tagged with:

-

- 24 replies

-

- quick-release

- qick release

-

(and 1 more)

Tagged with:

-

Yes,smaller # is a smaller needle.Here's a needle & thread chart that will help you to know what size needle to nbuy for your thread size.Yes smaller # is a smaller needle. https://www.tolindsewmach.com/thread-chart.html

-

Singer 211g 566 hook bobbin housing issues

CowboyBob replied to wendyp's topic in Leather Sewing Machines

I know it's too late BUT next time you get a machine the best way to clean it is spray it with WD40 or something similar & blow it out with air.The machine does not have to be super clean to sew.So what happens when it's taken apart is it ends up getting out of time.Your lucky here's a manual showing the timing & all the other adjustments for this machine. http://parts.singerco.com/IPsvcManuals/211U157A_165A_166A_566A.pdf -

Oops,I meant shuttle driver.

-

I just checked & found a supplier that has the carriers for the 78's,

-

Your die size helps determines the machine needed.As the tonnage increases so does the size of the cutting board,the 10T is 29.5x15 3/4",16T-31x16.5,24T-47x19.5.

-

I'll never forget the look on a longtime Boss users face after he sewed his knife sheath on the CB4500.The ones he had a problem with is almost 5/8" thick @ the top down to 5/16" at the tip.The sample he sewed on his Boss looked good until he came up from the tip,since it was thicker towards the top the stitch length shortened by almost 1/2.When he sewed on the CB4500 & looked at it he said I'll take it,traded the Boss in & haven't heard from him since. I'm not trying to knock the Boss but just wanted to let people know it helps to have a walking foot & feed dog for even stitches on a taper or going over seams.

-

Look for 16x2 it's a small shank leather point needle the same length as a 16x257.

-

Most needlefeeds take a larger shank then the 16x257,the same length is 135x5 or for leather 135x8.

-

For an easier reference look up Singer 16-188 (same machine w/o reverse) it should sew up to 20 oz & it'll take #138 thread w/o a problem.You'll probably want to take that motor off & put a servo motor on it for better speed control.

- 1 reply

-

- consew

- walking foot

-

(and 1 more)

Tagged with:

-

Yes,I found a 310 parts manual & it looks very similar to your model.

-

Could it be 210?

-

They will sew around a total of 20oz.

-

Use the new 794S or D for leather they old 7x2 original Singer needles had small eyes in the so you had to use a couple sizes larger than what you need than if you use the newer style.Also the newer needles have a scarf in them that allow you to adjust the shuttle closer to the needle reducing skip-stitches.

-

96K51 bottom stitch issues with 207

CowboyBob replied to plinkercases's topic in Leather Sewing Machines

Just because the manual states a #23 needle as largest doesn't mean that you can use a thread for that size needle in this machine.The 96 is a light duty high speed tailor machine for thin threads like #69 & if your real lucky size #92 might work.The old Singer 31-15 with the oscillating hook can barely take a 138,a 16 class Singer can use a #138 real easy because of the bobbincase design. -

If it bunches underneath it can be either threaded wrong,not enough tension or I've also noticed that the #138 usually only works on large bobbin 29 machines I always recommend #92 as max on a small bobbin.Also if your gears are worn giving the shuttle driver some play it doesn't allow the shuttles to spin all the way forward to release the thread of it.

-

Timing got off with reducer pulley!

CowboyBob replied to rockthecasbah121's topic in Leather Sewing Machines

You say your having issues with the bottom thread ? What do you mean & state size of thread & needle your using. -

Yes,they are big ,old & usually sew great.A few parts interchange with Singer 7 class,but be careful with the bobbincase tension spring they are real hard to find.Here's a pic of a 11-36 that sews up the arm(from left to right) they had quite a few variations of this model.

-

Stitching through Kydex and leather with a Shapeoko CNC

CowboyBob replied to joshhartung's topic in 3D Printers and Lasers

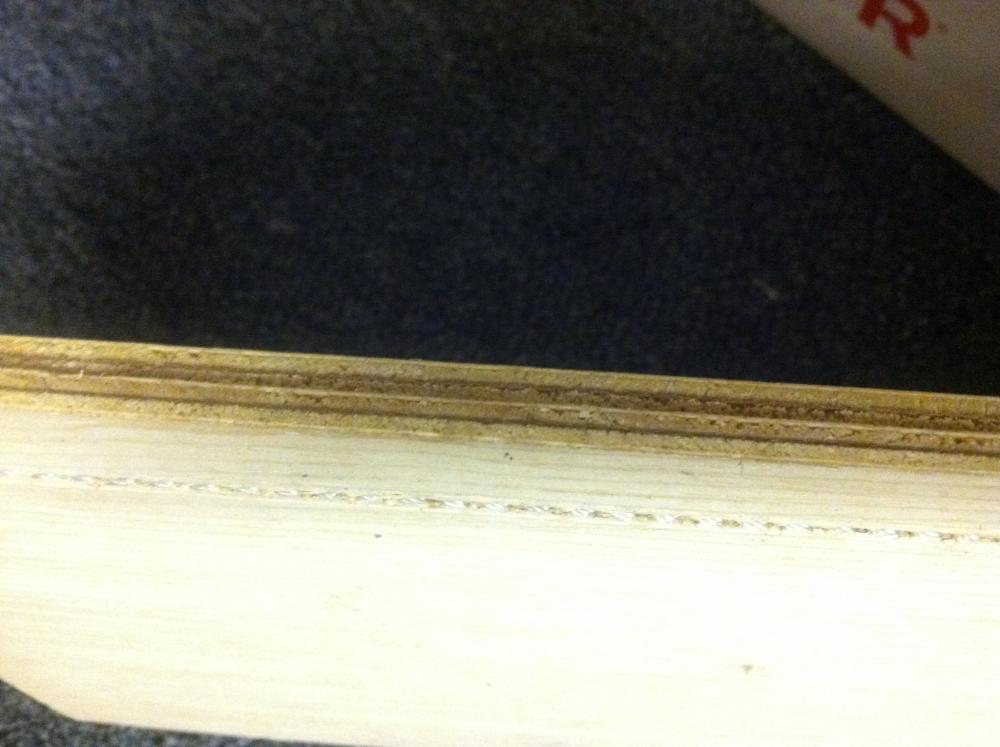

They go though the leather & Kydex real easy.It just takes a little minor tension adjustment for the Cowboy CB3200 to sew Kydex.Here's a pic of 10mm or 13/32" of plywood ,slightly under 7/16" thick that one sewed. -

Durkopp Cl 17-1-1 Antique Leather Sewing-Patching Machine

CowboyBob replied to rgerbitz's topic in Leather Sewing Machines

Ahoj Meznik, Yes the small 29 bobbin case can be made to work BUT it takes a lot of grinding to get it small enough to fit. -

-

Atlas Friction Clutch Singer Walking Foot 119-1

CowboyBob replied to Bob Haley's topic in Leather Sewing Machines

Yes,we have some ,I'll need to know the inside & outside dimensions.

.jpg.d60258221c476480a6e073a8805645bb.jpg)