-

Posts

1,299 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by TomE

-

Guess I'd better learn how to sew. The gal I married was a skilled seamstress but she hasn't sewn much in 40 yrs. Hope to lure her back into sewing as my teacher when/if she ever retires.

-

Bridle leather is difficult to burnish - fluffy fibers stuffed with fats and waxes. The best method I've found is to dye the edges with a 50:50 mixture of Pro Dye and Martin's Edge Solution then burnish while wet. Be generous with the dye/edge solution. I start with a wooden slicker on a burnishing machine then finish with canvas but canvas only will also work. Can do a bit of sanding then apply another coat if needed. Your file organizer is first rate craftsmanship.

-

Fiebings Pro Dye (formerly Oil Dye) has less tendency to dry the leather compared to Fiebings Leather Dye. I think both dyes contain an alcohol based solvent, which is why I avoid dip dyeing projects. A light coating of neatsfoot oil after dyeing seems to correct the problem. I also apply conditioner as a final step.

-

Thanks, @Wizcrafts. Will be fun to experiment once I get familiar with sewing lightweight fabrics.

-

Second set of rolled handles ever done. Tote Bag Repairs

TomE replied to YinTx's topic in Show Off!!

I posted a writeup on halter making in the saddles and tack accessories forum. -

Second set of rolled handles ever done. Tote Bag Repairs

TomE replied to YinTx's topic in Show Off!!

The handles look very nice. I use Stohlman’s method for handle #17 in Case Making v. 2 for a rolled throatlatch on horse halters. Might be too stiff for a bag. -

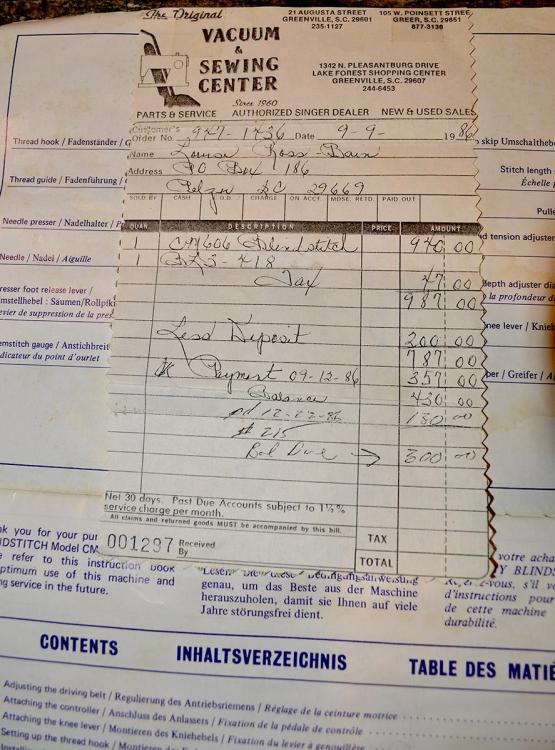

Got a bit far afield but couldn't pass up these Juki blind stitch (CM-606) and loop stitch (BL3-418) machines for $120. Seller's grandmother paid considerably more in 1986, and the lack of wear on the foot pedals suggests either grandma sewed in stocking feet or these machines haven't had much use. Hope the serger will handle canvas and the blind stitcher, well it's pretty cool even if I don't find a legitimate use for it. Will be oiling them and working on learning to adjust and use them this week. My excuse to my wife for this purchase is to sew fabric liners for leather bags. Maybe even horse blankets? I have the user manual for the blind stitch machine and I'm looking for a manual for the loop stitcher. I see several online sellers who want $10-$20 for a photocopied manual. Would welcome suggestions for books or online resources for learning fabric sewing techniques.

-

This product is designed for that purpose. It penetrates the leather and holds the fibers in place. It is water based and I dilute it 50:50 with water and apply it in 2 coats, working it with a glass slicker. It is flexible and appears to hold up as well as the moss-back of bridle leather. Folks also use waxes, PVA glue, and burnishing compounds for this purpose.

-

I've been pleased with Ron's Leather Tools French edgers if you decide to make a change. Worth a look.

-

Rethread your machine making certain that it's threaded correctly. The thread path on a Class 26 has a couple of subtleties, there's no written instructions (?), and I watched several different instructional videos before I realized my mistake. That said, it's a handy little machine that does a great job running through all sorts of materials and thicknesses.

-

No experience with driving harness and tack. The buckle type billets that I see for riding bridles and reins are constructed similar to the smaller/lower set in your pictures, except they typically have a fixed loop in front of the buckle and one or two loops behind. I like the looks of your billet and think it would be at least as strong as the other. Perhaps a running loop on the front/bit end of the buckle would keep the buckle flat and tidy?

-

Thanks. Fun to see this method. I make rolled throatlatches for horse halters. I posted a description of the method in the Saddles and Tack Accessories forum.

-

A classic. Very nice work. Do you trim the edge of the round handles after sewing? How do you get that close to the edge? Now I see that it is hand sewn. Lots of work!

-

Very pretty. The background nicely sets off the artwork.

-

I think using a stitch groover is more about aesthetics than preventing wear. I would be interested in people's experiences with stitches breaking because of abrasion. I've only seen it happen on the toes of my work boots when they are well worn. For horse tack it is usually the leather that breaks, not the stitches. As a corollary, I don't see that machine stitching unravels and is somehow inferior to hand sewing, but I digress. I don't use a stitch groover for sewing because I'd rather not remove the grain, the strongest part of the leather. I do use a heated crease fairly often, but mainly for decorating straps that aren't sewn except at the ends for attaching hardware. To answer your question, if you like the look of stitches in a groove I'd keep doing it. I think the quality of tannage and weight of the leather will determine the durability.

-

How much to charge for your leather goods?

TomE replied to GrampaJoel's topic in Leatherwork Conversation

I am enjoying the collective wisdom and experiences of the commenters (commentators?) in this thread. Lots of good insights. Thanks for sharing your thoughts. -

Creasing belts - Wet creasing VS Heat creasing?

TomE replied to LzCraft's topic in How Do I Do That?

Yes, a heated creasing iron will quickly cool on cased leather, not to mention scorching the leather on initial contact. The crease should be warm enough to move smoothly but not so hot that it burns the grain. The heat serves to burnish the crease line. Start with light pressure to establish your line then press more firmly to finish. I usually go over crease lines twice during a project, first after burnishing the edge and again before applying conditioner at the end of the project. When I am blocking loops I re-crease the damp leather without heat. -

My day job mucking stalls and making/taking care of foals keeps getting in the way of starting a leathercraft business from my hobby. However, the dream lives on. I use scrap to practice construction and finishing techniques, and in the process figure out what I'm good at and what I enjoy. I bought a larger splitter with plans to make small bags and cases from bridle side leftovers.

-

I think it’s been 40 yrs since I saw a CB radio. :)

-

Probably would include a fixed loop/keeper to secure the free end of the strap so it doesn't lift off the Sam Browne stud. A stud hook is a related device that attaches the bit to a bridle or reins. It's a little more complicated to install. Typically sandwich the base of the stud hook between 2 layers of leather and include fixed loops on either side of the hook. Definitely not quick release.

-

See my comment above.

-

This thread has some useful information on refinishing upholstery. @Wizcrafts mentioned this refinishing system https://www.wood-n-stuff.com/ that I'm thinking about trying on a faded red leather chair.

-

That makes sense. Couldn't see the difference between 1.02mm and 1.09mm diameter. I'll need to make a smaller awl for that #4 needle and #92 thread, and maybe pick up a new set of eyeglasses.

-

@Hazza I was curious and checked what I had on hand. The John James needles on the left are sizes 1/0, 003, and 004. The 004 is smaller, and the other 2 are the same diameter and slightly different lengths. On the right are Osborne needles in 18, 19, and 20 gauge. I use the 19 gauge needle with #207 bonded nylon thread, and the 18 gauge needle for #277 thread. I've bent them using pliers when overstitching in thick leather, but I've never had one break. Very happy with the Osborne needles.

-

That is one gnarly bag! Guitar slinger shoulder strap is the topper. Put a smile on my face. Hats off to your creative talents.

.thumb.jpg.2c51715cc2d68401608c542e3748f4ab.jpg)