Search the Community

Showing results for tags 'needle'.

-

this might be a stupid question but what size thread do i use for john james needles Size 17 (2/0).

-

when I try to sew two pieces of sheepskin together the needle keeps getting stuck does anyone know of a tool I can use to pull the needle through like a pliers or something.

-

Hi there, I have the green Sailrite leather Machine Can anyone help on why my sewing machine may be doing this? If the leather is dampened or completely dry i get these “bubbles” or “blow outs” I’m using V92 thread and a size 20 needle. It does this regardless if I use one or two layers of 2-3oz leather or 4-6oz leather.

- 2 replies

-

- leather

- sewing macine

-

(and 4 more)

Tagged with:

-

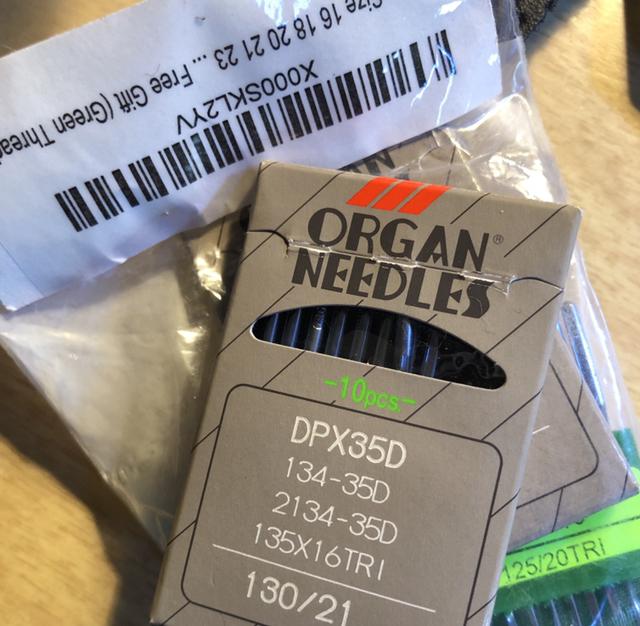

So I finally spent some time trying to understand industrial sewing machine needle sizes and systems. As a reference I’d spent some time going through the information shared on the needles and threads sticky post linked here from 2011: Here has been the main thread for this machine: I bought this machine used (obviously) but the few needles that came with it are nearly unmarked and are about 1.52” long. So I wanted to share with you what I’m doing to find out what size these last few existing needles are that I have that go in my Pfaff 335 clone (it’s a Necchi 840-100 rotating bindery cylinder arm machine). I’d actually purchased a full set of 135 x16 (common needles for walking foot machines for use on the leather, in place of the 135X 17 needles). These are about 1.7” long. These needles were too long. I actually had to adjust the Needle bar very high to allow these larger needles to work. As I adjusted this, the Needle bar eventually touched the top of the machine Case and I realized this wasn’t going to work. I couldn’t find needles that matched the 134 needle system that the Necchi manual described. Eventually I found some! Here are the next set of needles I’m trying: “10 Groz-Beckert Gebedur 134 135X5 DPX5 Titanium Sewing Needles SINGER PFAFF JUKI” https://www.amazon.com/dp/B0759VHZVP/ let me know what you’ve used on this machine or similar. BONUS: if you’ve read this far and you’d like an assortment of 50 various Organ needles for 135x16tri in sizes 16, 18, 20, 21, 23 (I’ve only used two or so) …you can have them! heres a pic of those: dm me your address and I’ll get them shipped! Best first offer or free! Luke

- 4 replies

-

- pfaff

- cylinder arm

-

(and 1 more)

Tagged with:

-

Hi, I am brand new to sewing machines, I purchased a new double needle post bed sewing machine recently (ZJ24028-2) and I’m having an issue with the handwheel being hard to turn at 1st and now it does not turned at all, I oiled the machine and still nothing the bobbin case is empty there’s no thread or anything in it, I’ve looked online to try figure it out but I’ve found nothing to help me figure out why it won’t turn... id really appreciate the help thank you.

-

I purchased a Consew 118 and it won't stitch. It's obvious from cleaning and observation that the needle is very deep when the hook passes above the needle. I have the operator guide but not the service manual. It's obvious I need to adjust the needle bar height and timing but I cannot find any documentation. Plus, I can't even locate the screws to adjust the hook timing, it appears to be one factory assembled unit. Can anyone guide me to a service manual, or video, or share any information to help me adjust the needle bar and timing for a Consew 118? Thank you very much for your help. Mark in Colorado. PS: One picture shows how deep the needle is and the hook is at the very top where the uppper notch is. The other picture shows the back of the hook assembly where I thought I would find the timing screws, but there are none. thanks again.

-

- sewing machine

- needle

-

(and 1 more)

Tagged with:

-

Does anyone have step-by-step pictures of how you knot your thread when threading a needle for hand stitching? I am having trouble with my knots slipping undone as I stitch and would love to not have to re-tie several times. Thanks!

-

Hi, Have a question about a type of stitch and also its strength. The stitch I want to know about is in this video below. It is the first stitch he does, single needle method. My questions: -1. What is the name of the stitch. He says it gives the look of the 2 needle saddle stitch method. Is it still called a saddle stitch? -2. Also is this stitch strong and if one stitch breaks, say in the middle, will they all pull through? 3-. Is there a different way to start and finish this type of stitch? I cant end it like he does with putting it between the two pieces. I just cant keep it tight to do it. So what I have been doing is when I get to the end on the second pass that takes me to where I started to end the stitch, I then just go a few more holes the opposite way(so 3 times through each hole) just a few holes, cutting it and adding a dab of glue. Appreciate any help and thank you Hand sew leather video

-

Hello, I've recently purchased a cobra 26. Just a couple questions... When replacing the needle the eye goes from left to right but each side is slightly different. I had it in and the needle started hitting the case and broke so it's now going in the opposite. Is this normal? I was told just to put in the needle so you thread laft to right. Second, I've een trying to dial down the tension for the lightest weight thread the machine takes 69 as I'm waiting for heavier thread in the mail. Both with the 69 and 138 I can't seem to tighten that bobbin case anymore to get rid of the loop on top. I've tried 138 in top and bottom realizing maybe 69 is just a bit too light weight. Any suggestions?

-

I don’t have any prior experiences handling sewings machines and have always just handstitched bags and wallets. For my first machine, I am considering a second hand Juki LS-341N. Is it a good machine for stitching 2 to 3 layers of 2mm vegtanned leather? How about oil or chrome tanned leather, denim, or canvas? What’s the thickest Vinymo thread that I could use with the Juki? For needles, Schmetz seems to be a good option. What sizes work best with Vinymo? Thank you!

-

Okay I know you are all going to tell me this is a bad idea and that I should just buy a real leather sewing machine, but I don't have the money to make the investment yet, so I wanted to try this first. If I were to try sewing softer oil tanned leather with a normal sewing machine, what should I buy to make it work right? I hear that you can buy walking feet for normal sewing machines along with leather needles for them too. What do you guys think of that idea and what needle/ walking foot should I be looking at? Thank you for your advice! -Cole

-

Hello, As I continue to set up and use my new Cobra 4 sewing machine I have been speaking with the Leather Machine Co. to figure out a strange issue. I thought I would also put it up on here in case others have had the same problem, or in case we find a good solution, in which case - we can all benefit! Upon installing either the stirrup plate or holster plate, it is apparent that the needle comes down very close to the right hand side of the slot. On the holster plate the needle pretty much touches the right side of the slot. This is with the plate installed as far to the right as possible. In the instructions it says to have the needle more to the left side of the slot when using any of the plates. Basically a business card thickness between the left side of the slot and needle is necessary. If it is in the center or to the right of center you risk skipped stitches or frayed thread. - So far they have sent me out a new needle clamp that screws up into the needle bar. The new clamp did not change the position of the needle at all. - I then made a suggestion that perhaps the stirrup plate and holster plate need to be ground down on the right side to allow more play when installing. My reasoning is because the needle seems like it comes down center or just off right of center of the feed dog (when installed), and that the top stitch plate seems to be installing just fine as per instructions. I only have issue with the holster or stirrup plates. I am still waiting to hear back about that suggestion for grinding the plates down, I certainly don't want to patch something when there is a better way to adjust/fix though. Anyone else had to grind the plates down to fix their placement on these Cobra 4 machines? I'll keep updating as I hear back.

- 4 replies

-

- cobra

- holster plate

-

(and 2 more)

Tagged with:

-

I've been sewing a lot, but only on others machines (industrial walkingfoots as well). I picked up a Brother LS2-B837 the other day and changed from a thin cotton thread to a tkt 20 (tex 150) nylon thread. It had a 130 needle, which would be about right accordingly to the thread brand (120-140). Seams to do well on the slide test. (Tried 120 and 140 as well) At first I tried with original thread tension, but it broke the thread. I losened both top and bottom tension a little, the bottom so that the bobbin doesnt slide down holding it in the thread, but loose enough to slide a bit with a gentle "jojo move". I would say its on the looser end now. The top tension I did loosen a lot, because the thread did not move at all, to a point where it falls off from the tension wheels. By the moment it will curl the top thread, and do a lot of birdnesting. Ive tried all day, with my limited error searchings skills, and I'm not even close to make one normal stitch, feels like a needle in a haystack!

- 23 replies

-

- leather

- birdnesting

- (and 5 more)

-

Hey yal long time no post! Hoping some pros can help me with something. I'm looking for experiences, not just google articles, hence why I'm here! I have a 810 post bed machine. I had started a project (which is now complete), sewing some sneaker uppers, but toward the end I snapped a needle and found I had been sewing with a size 22. It's ok, but I really wanted to sew with a smaller needle to get a smaller more "high end" looking stitch. I went to put it in a new needle that was provided, but none of them worked. None of them would catch the bobbin thread, from size 16-21. Come to find out they sent me the wrong needle system, as I needed dpx5 and those werent it. So now I'm on ebay trying to find needles but all of these numbers and letters are confusing. There are lots of options. 2 part question: 1. If I buy needles, as long as it's the right system, can I use a smaller size?? For instance, it's seems my machine is set for a size 22, will a size 18 or 20 work?? For 69 thread. 2. If that answer is no, is it worth changing something internally so that I can sew with a smaller needle? I would have to be walked through this over the phone, as I am 4 hours away from the nearest professional. For more background, I don't plan to sew over 6 oz of leather. I sew Python and lamb skins, and would like to sew croc and stingray soon. But I also want to sew fabrics, like Pendleton and suedes, which look like requires ball points but leather requires diamond. (Any info on points appreciated too) Any advice?? Thank you!!!!

-

I bought a pack of hand sewing needle from tandy...I bought them because it was a 200 ct (guessing) and I was at the store. I have already broken 3 at the bottom of the eyelet closest to the needle end on one note book cover. Does anyone know where I can buy quality SS needles (S30V.. joking)? And im using 1.0 mm Ritza,what size should I get? Does anyone have a chart for stitching needle and size thread? Any and every chart will do

-

Hi, I have a techsew 2750 and Im looking to get some 135x16 LR to fit it in size #19, 20 , 21 . Does anyone have a source for those.. preferably in North America, Ideally in Toronto. Thanks!

-

I bought a Cobra 4 a couple of months ago. It's brand new and needed a little adjustment when it arrived to get going. Things were going great until three weeks ago. When I returned from a convention in Texas, problems ensued forcing me to hand stitch the projects I have waiting. I contacted Steve, but we don't have a resolution yet. Here are my issues I can use help with. Presser Foot: It is coming up as the needle is traveling upwards at the end of stitches. Needle: Bending on shuttle and breaking. I've had to force the needle up higher to see the end in the window. I've been using channel locks and a lot of elbow grease to get it done. This cannot be the best way but is necessary. Bobbin: I can pick up the bobbin thread with my needle when initially change out the bobbin, but after that, nothing. I find myself just poking a lot of holes in my leather rather than stitching. I'd be grateful for any assistance. I have projects customers are waiting on, but I'm having to hand stitch everything from chinks to holsters, saddle skirts and harness. Thanks, Philip Crabtree www.CrabtreeSaddleWorks.com

-

I bought a Pfaff 145-6C/D H3SMN. Unfortunately the shuttle doesn't catch the upper thread. I guess that the needle System I use is the wrong one. I googled and found that it needs 134-35 needles. Is that right? For me the needles seem to be to long. The machine came with 459R needles which have a too small upper part. 621 which are too thick and 134 needles which seem to be too short. I hope somebody can help me. Thank you in advance.

-

I'm in need of a Needle & Thread size guide for my Cowboy 3200 along with different needle types for material. I need to repair a a couple of heavy duty canvas tarps, but need to find the correct needle size and thread for my application. Thanks in advance.

-

Good afternoon, I am adding an SD28 to my toolbox and even though a lot has been written about this and the pedersen machine, I can not find which thread size corresponds with which needle size. the pedersen 308 manual states : use 6 strand twisted linen, waxed on the bobbin, unwaxed on the upper. needle #5 goes with thread #5, #6 with #6 etc. but these notations are from way before I was born and I have no idea which thread diameter goes with which number. Is it as simple as measuring the needle's blade and take the same diameter thread? Thanks in advance, friendly regards vaporlock

-

Title says it all. Does anyone have specifics on where the needle should be in relation to the shuttle hook during operation? I can see where it's adjusted, just want to put it in factory specs. Manual doesn't address this specifically. Thanks so much! Bill

-

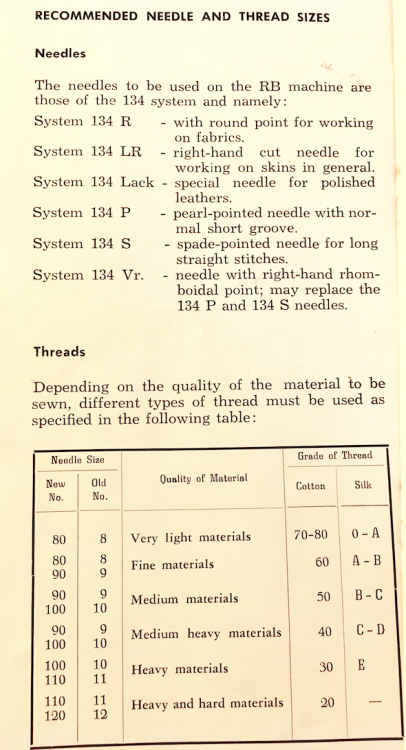

How To Select The Proper Thread For A Material (Leather)

Evo160K posted a topic in How Do I Do That?

While researching how to restore a Claes sewing machine, I came across a number of general comments on thread selection. The most frequent comment was, the thread selection is determined by the material being sewn and the needle size is then determined by the thread and size selected. Being new to sewing, sewing machines and this fine website, may I please ask: what specifically are the major factors to consider when selecting a machine thread for any material and for leather material in particular? I'd like to understand the reasoning that goes in to the choice Thank you, thank you very much. -

I recently purchased a Singer 31-15. It came with two sets of needles. The first set of needles were marked "Singer" on the shaft, and from the eye size, look to be either #16 or #18. These have no scarfs on the needles. The second set of needles were still in the package and are marked Organ needles 16x257/LR (110/18). These have a scarf on each needle. Both sets of needles look nearly the same; they are both the same diameter and length (except for the scarf on the second set). I was using #69 thread with the Singer needles to set up the machine, and got everything working fine. It sews correctly on either cloth or leather. Without making any other changes, I then tried to use the Organ 16x257/LR leather needles in the machine. These did not work. They will not catch the bobbin thread. In both situations, the groove on the needle was to the left, and threaded from left to right. However, when I reversed the Organ needle (groove on the right, still threaded left to right), it would sew maybe a dozen stitches before breaking the top thread. Anyone have any ideas how to the leather needles with a scarf to work?

-

Hi Folks, I'm running what looks like a diamond point size 200 needle, the one that came set up on my Cobra 4, with size 277 bonded polyester thread. On my back stitches, the needle cuts or shreds the stitches on the back side. The backside ends up looking frayed and, well, bad. Can anybody suggest technique(s) for avoiding this? Do you try to shift the leather sideways so that the needle drops to one side of the thread that's in place already? Should I try a different needle point shape? Thanks in advance, Steve

-

Hello, Recently purchased a consew 206rb-5 and this site has been a great help, but I am a little confused about the needles. I have read many places on this board that "135X16 is for leather and135X17 is the needle type used for fabric". I went to my local sewing shop and they said I was confused and that "135x16" and "135x17" are sewing needles "systems", not sizes. I am looking for the proper needles to sew leather and canvas with #138 thread. I know I probably want a size #22 needle, but the "system" thing is still confusing me. What is the difference between a "135x16" and "135x17" needle? Any help is greatly appreciated! -Grant