CowboyBob

Contributing Member-

Posts

3,312 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by CowboyBob

-

Yes,a CB3200 would be a great addition for you as it'll sew the thicker leather with thicker thread that the other 2 can't.And of course the other ones can sew thinner leather than the CB3200 so you'd have no excuses to get the job done. LOL !

-

How to perform a back stitch without a reverse machine

CowboyBob replied to Bradford's topic in Leather Sewing Machines

Yes,spin it around is the only way to get the holes to line up. -

The 29K60 will be a handy machine to have with it's cyl arm.At least your getting machine that you can get parts for.

-

Looks like a good machine,timing belt looks good too.Has a large pulley on the motor easy to change or upgrade to a servo.

-

I just saw this post.You can use up to #138 with a dia point needle size #22. Here's needle & thread chart;http://www.tolindsewmach.com/thread-chart.html

-

It will help them if you know the brand & model# of your current motor.Should have a tag on it with all the info.

-

You need a 2-spool serged edge for patches,so take out the left needle & use the right one only,you'll also a need to change the overcast looper to an open one(converts to 2-spool) so you can sew the edge w/2 spools.

-

What are your thoughts on separating the Arm

CowboyBob replied to Evo160K's topic in Leather Sewing Machines

-

What are your thoughts on separating the Arm

CowboyBob replied to Evo160K's topic in Leather Sewing Machines

Around 15 min into this movie you'll see how they attached the castings & also the how they painted them. http://movingimage.nls.uk/film/1592 -

What are your thoughts on separating the Arm

CowboyBob replied to Evo160K's topic in Leather Sewing Machines

You'd be surprised how hot a machine can get w/a heatlamp under it & some tin foil over it . -

Many times if you can carefully w/pliers or vice-grips pull the needle out & get pressure off the screw it'll spin right out.

-

What are your thoughts on separating the Arm

CowboyBob replied to Evo160K's topic in Leather Sewing Machines

I believe sometimes some things are better left alone,we have split machines apart many times,it isn't easy to get the screws out(use an impact driver),also once you get them out you also have to pry & work the casting back & forth to get the (2) big taper pins out that they put in there. -

Great buy,we have the needles & awls in stock for in packs of (10) f/$20.00.

-

Singer 7-33 Stitching problem & parts

CowboyBob replied to hackish's topic in Leather Sewing Machines

Lift the foot up all the way & you'll see where it hits the casting,you take all the parts off & put it in a bandsaw & cut the underneath side of the casting(where the needlebar comes out) & fill in the slot on the lifter handle backet (flat piece in the side) w/braze so the slot is shorter. -

Lee,nice looking machine & video ! CD the 42-5 was made for larger thread up to #346 where the 16 class can use up to 207 with some fiddling.

-

Singer 96k49 working in reverse

CowboyBob replied to CherieKingsley's topic in Leather Sewing Machines

There might be a lever inside that the stitch length knob hits to make your stitches longer & shorter,what I think happened is when he turned it all the way out it dropped down,so what you need to do is,turn it all the way out,look in the back access plate & push it in reverse so you see what's moving & take a screwdriver & hold it up while you turn the adjuster back in.You'll probably need to hold the lever down as you turn the knob back in too. -

Singer 7-33 Stitching problem & parts

CowboyBob replied to hackish's topic in Leather Sewing Machines

The Seiko way will keep the thread in the tension better.BUT either way doesn't make a difference in the way it sews(won't stop it from skipping) You might want to try alittle more foot pressure. -

Singer 7-33 Stitching problem & parts

CowboyBob replied to hackish's topic in Leather Sewing Machines

You might need to adjust the hook closer to the needle,there's a large screw underneath to loosen ,you want it as close as you can get w/o touching the needle. -

Were machines used for leather sewing, Civil War era?

CowboyBob replied to Tallbald's topic in Leather History

I found this on ISMACS The No. 3 Standard (Picture and Text Courtesy of Dorothy Brumleve) In 1852 a modification of the first Singer machine was put on the market and was called the "No. 1 Standard"; it was essentially a machine for manufacturing purposes and several hundred thousand were sold previous to 1880. It was succeeded by the "No. 2 Standard" in 1854. This also was similar to the "No. 1" but had greater capacity; it was fitted with either the rolling, the vibrating or the spring presser, according to the class of work it was to accomplish. It was heavier than the No. 1 and had more room under the arm. In 1856 the "No. 3 Standard" was brought out. This too was similar to its predecessors in its mechanism but was especially designed for stitching leather in carriage trimming and harness manufacture. It has 18 inches clear space under the arm and is a standard machine to-day [1914] for its purpose. -

Were machines used for leather sewing, Civil War era?

CowboyBob replied to Tallbald's topic in Leather History

I don't know a lot about Landis #1 history either,although I've worked on alot of them & sold them over the years,they are a pretty good old machine.I was told once that they quit making them around 1900 but I've never talked to anyone that could say when they started making them. -

Were machines used for leather sewing, Civil War era?

CowboyBob replied to Tallbald's topic in Leather History

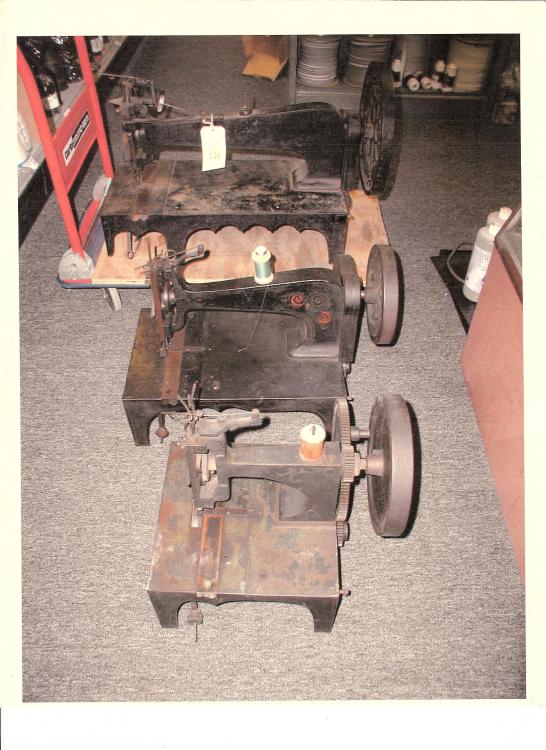

The largest one is a Singer model # 3-1 & supposed to sew 1/2" of leather? Sails or whatever needed sewn.I think they needed the big wheels to keep the momentum going has they were treadled. -

Were machines used for leather sewing, Civil War era?

CowboyBob replied to Tallbald's topic in Leather History

I wished I knew more about these old machines too! The smallest machine is Singer first Industrial model & the ser# on it dates to 1858 so it might of done some civil war sewing?? The 2nd one back is a Standard or #2 & the larger one is #3 for harness work. They all use a wooden pitman arm to the treadle pedal insead of a belt like the newer machines & they are pretty hard to treadle ! -

We use a grinder & then buff them or you can use a Dremel to smooth them down.

- 4 replies

-

- thompson

- mini-walker

-

(and 2 more)

Tagged with:

-

Keeping A Sewing Shop Going During Grid Outages

CowboyBob replied to cdthayer's topic in Leatherwork Conversation

Our neighbor had a big oak tree & it seemed like every winter after we fist moved in a branch would fall off ,hit the wires & we'd be out of power.We after the 3 or 4 time I got tired of it so I bought a 2000 watt Honda & when the power goes out I shut off the main breaker,plug it into an outside outlet & have enough to run the furnace & a few lights.It's handy to have because I've deal w/the Amish & take it with me to run machines.We had a storm 2-yrs ago in the summer & need it too.I guess what you get depends on how much power you need.I think the one I got set me back under $1,000.00.