Scoutmom103

Members-

Posts

612 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Scoutmom103

-

19th century Hugo Werteim shoe patcher

Scoutmom103 replied to RichardPorley's topic in Leather Sewing Machines

Love the stand. It's beautiful. Really nice job bringing it all back to life. -

Very nice

-

I don't know saddles, either, I think it's beautiful.

- 26 replies

-

That looks very close and nice. Thank you for Sharing.

-

First motorcycle tank cover

Scoutmom103 replied to HamiltonLeather's topic in Motorcycles and Biker Gear

Nice. A lot of stitching. -

WIP Passport cover

Scoutmom103 replied to ABHandmade's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice carving -

Threepersons Done!

Scoutmom103 replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Those are beautiful, and thank you for showing your steps in creating them. -

For leather soles, etc. Try Landwerlen Leather Address: 365 S Illinois St, Indianapolis, IN 46225 Phone: (317) 636-8300 M-F 8-5 Sat. 8-noon It's like stepping back into the Late 1800. They cater to the cobbler business. They don't really have a website. They do have a FB page, sorta. They use Instagram. They will ship

-

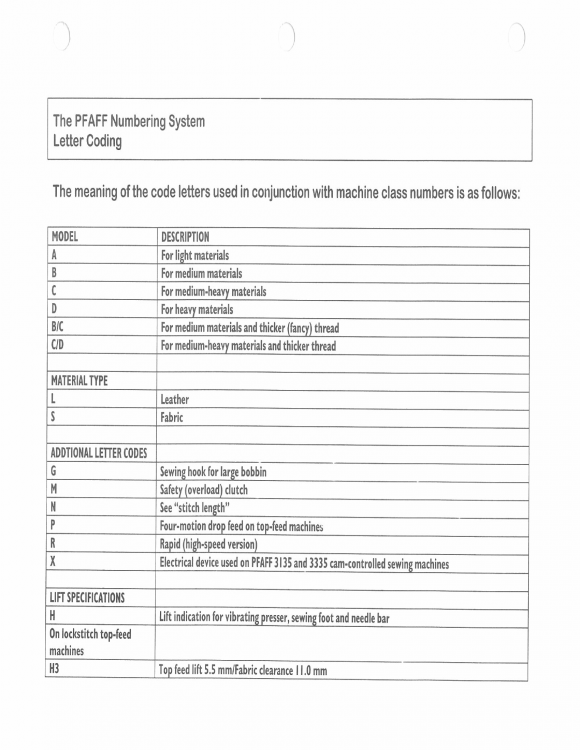

what class Pfaff 145-H-3 BSN?

Scoutmom103 replied to plinkercases's topic in Leather Sewing Machines

-

Suggestions for slowing down machine

Scoutmom103 replied to rockthecasbah121's topic in Leather Sewing Machines

I watched a you tube video, where someone changed the pully, and they used a specialty tool to remove the pully. I think it was called a gear puller. They are available at auto parts stores. -

Couple of items this week

Scoutmom103 replied to YinTx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

very nice -

Messenger bag 2.0

Scoutmom103 replied to alpha2's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I really like the blue thread against the black. Is it also out of black bridle? I also like the removable holder.- 11 replies

-

- messenger bag

- purse

-

(and 1 more)

Tagged with:

-

Love the wood handles. How did you get the glass to stay in the handle?

-

Celtic Knot Tutorial for Railrider1920

Scoutmom103 replied to immiketoo's topic in How Do I Do That?

Thank you for the video. I like the weights you use.- 26 replies

-

- bevelingislife

- celtic

-

(and 1 more)

Tagged with:

-

Latest Project

Scoutmom103 replied to Handstitched's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Beautiful work. -

Holster rig I recently finished

Scoutmom103 replied to corkscrew's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice -

Nice looks like a lot of work for a good cause.

-

bench grinder for burnishing

Scoutmom103 replied to SonderingSusan's topic in Leatherwork Conversation

They do make holders that essentially turn a Dremel into a small drill press. The link below shows some pictures: https://www.bing.com/images/search?q=dremel+drill+press+table&qpvt=dremel+drill+press+table&FORM=IGRE Here's an amazon link for one of the versions: https://www.amazon.com/Dremel-220-01-Rotary-Workstation-Station/dp/B00068P48O -

Very Beautiful. Love the design of the peacock and the detail around it.

-

Billfold for a Friend

Scoutmom103 replied to Rolandranch's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Love the horse. It's beautifully done.- 22 replies

-

- rolandranch

- figure carving

-

(and 2 more)

Tagged with:

-

Nice

-

Singer Leather Sewing Machines

Scoutmom103 replied to Trevor Baret's topic in Leather Sewing Machines

That would be wonderful.- 53 replies