-

Posts

1,653 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by alpha2

-

Latest Project

alpha2 replied to JimBilt's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Outstanding! What is it with people...like me, that continue to use a wallet until it falls apart? I just replaced mine a few weeks ago. When I actually took a good look at it, I was amazed at how worn it was. I wouldn't be surprised if I'd had that one for 15 years or more. I made one for my brother also, and he said the same thing. -

Rifle Scabbard Christmas Present

alpha2 replied to micktx's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice! Ya wanna hunt in my backyard? I'm good with it, but the city and neighbors might have a different opinion. -

Square card slots/pockets instead of T slots

alpha2 replied to Lalumiere's topic in How Do I Do That?

skive the edges down to make them thinner. You're missing some stitches, too. Check your tensions or technique. We do wan't to be luxurious, after all. -

Wow.That belt has seen some use!

-

Intersting order

alpha2 replied to chiefjason's topic in Gun Holsters, Rifle Slings and Knife Sheathes

If you're going to use a hole punch to end your belt slots, you need to cut between the holes at the outer limits of the slot. Either that or reduce the size of the hole punches. When you're working with sheet metal, that hole at the end is a stress relief point. Not really applicable to leather, in MOST cases. (End of slots in card slots comes to mind.) That's all I've got! -

My "new" beekeeper is my brother and sister in law. Their beeswax is a thing of beauty...at least compared to the tandy "stuff". As far as vitamin E is concerned...well, let me just say that I'm not ingesting the stuff, just applying it to leather. BTW, the leather seems to like it!

- 37 replies

-

- leather conditioner

- conditioner

-

(and 2 more)

Tagged with:

-

Nice! I would have totally overdone that, with excessive decorative cuts, etc. etc. etc. Now I know what it SHOULD look like. Thanks!

-

Pictures would make a big difference in estimating what would be required. "Getting the old stitches out" can be a chore if it was saddle stitched as opposed to machine stitched. Also, how it was glued prior to stitching will affect your time and effort. When I make a mistake gluing and/or stitching, prying and cutting works, but it's not fun, and if you want to make any money for your time, be sure to account for that.

-

First knife sheath

alpha2 replied to alpha2's topic in Gun Holsters, Rifle Slings and Knife Sheathes

This little gem here. I tape it in place and always leave the last letter in place while setting the next one. The only challenge is the "I". All the other stamps are the same size, the I is narrow. Also, you have to make sure to stamp the "I" lightly compared to the others ones. A lot less stamp going into the leather, so it comes out much darker if you give the same whack. The Tandy stamps have some flashing on at least one side of the stamp, so you have to sand them smooth to get them to fit in the guide properly. As for the "VFW", the angle was basically wing it and hope for the best. I admit I practiced it first! -

Sealer

alpha2 replied to mojave's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Good tips. I think I have a tendency to buff too soon. Impatient. -

First knife sheath

alpha2 replied to alpha2's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks, Mike! I have to admit that I'd read about screwdrivers on this forum. Just one more little priceless bit o' info. -

Well, I did a molded one for my folder, quite a while ago, but this is the first fixed blade type. A co-worker won a knife at a Harley ride a couple of weeks ago and he wasn't impressed with the plastic, (maybe kydex...) abomination that came with it. Their VFW Harley riders club is the "Warriors", and I knew he was retired from the USAF, so I worked up something with that theme. The wings logo was interesting, I didn't have a stamp that would do it right, so I used a couple of small straight blade screwdrivers. Their colors are black and yellow, and I didn't have the means to do the lettering in yellow, so I went with yellow Tiger thread in .8mm.

-

Sealer

alpha2 replied to mojave's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Thanks, Bill! -

Sealer

alpha2 replied to mojave's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

I've got beeswax, and I've got pure neatsfoot oil, but I don't know the proper ratio. Is it 50/50 or some other magical mixture? And, is it just rubbed in like saddle soap? -

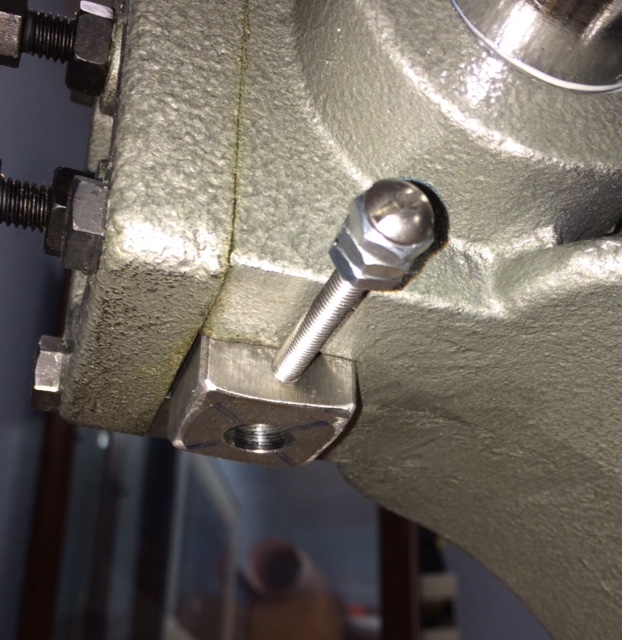

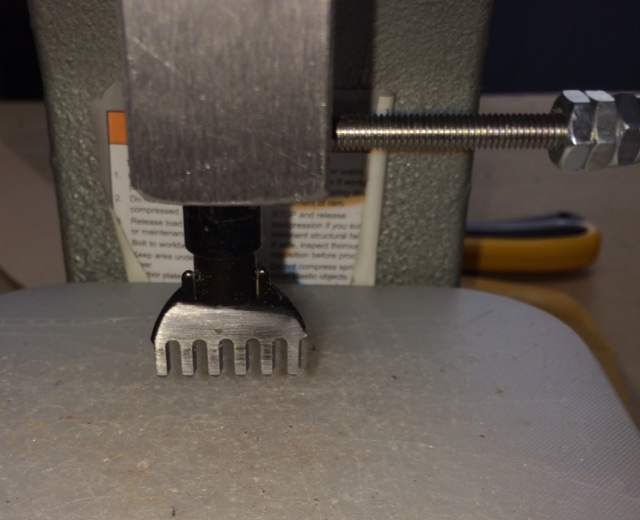

On the market for an Arbor Press - which one should I get?

alpha2 replied to Thatone's topic in Leather Machinery

I just got the Harbor Freight 1 ton press. I've spent some time in the last two days doing the upgrades to make it work well. Drilled the ram for stamp adapters, drilled and tapped for a locking screw to hold said adapters in. Ground off the bottom two teeth so I can ratchet the ram for most effective angle on the lever. It's all on You tube. However, there are a couple of things to watch for. If your drilled/tapped hole for the lock screw isn't RIGHT AT the bottom of the ram, you have to grind a bit off of the third tooth up from the bottom of the ram to allow the ram to ratchet. My press also rocks on the table, the bottom of the casting isn't flat. When I mount it to a board hopefully I can address that with wood instead of iron! I also found that I can't use the nice lockscrew with the big knob. It hits the press at the top, and can hit the bottom support when all the way down. Getting a longer one would help with the top conflict,but not the bottom one. Now I know why all the ones on youtube had a simple screw and use a screwdriver or allen key.- 2 replies

-

- arbor press

- 1ton press

-

(and 1 more)

Tagged with:

-

Well, there's yer problem! They're out of season! It would be like trying to get iced tea in Michigan in the winter. I was astounded to discover there's a season for that in that place.

-

If you've got a number of people in the same area to go in on a joint deal, that's great, but if you add in addl. shipping to the various individuals, it goes back up again. From what I've seen on the forum, we are a "geographically diverse" group.

-

Belts, Bracelets & Key Clips By Raw Leather Goods Llc

alpha2 replied to AgentOrange's topic in Old/Sold

Oh, yeah, I see that now. Some of the forum threads are still on the first page quite some time later. Guess I missed the strip of leather with a snap for 20 bucks. Dang. I can see why they needed crowd funding. Oh, well, moving on. -

Belts, Bracelets & Key Clips By Raw Leather Goods Llc

alpha2 replied to AgentOrange's topic in Old/Sold

Wow. Just wow. I must have missed the April 1st posting. -

That's it! I'm only buying pre-dyed leather from now on!

-

Money sent via paypal. I guess I still had an acct.

-

Well, heck, that's easy! I tend to over engineer when I'm bored.