Search the Community

Showing results for tags 'awl', 'stitching' or 'barry king'.

-

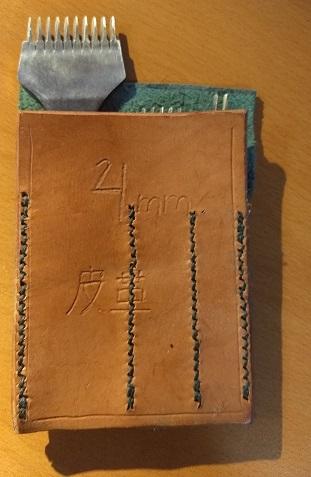

This is my first wallet and attempt at stitching. 4-5 chrome tan leather. Never mind the cross, I had a brain fart and thought I try stamping that after it was put together. Been carrying it for about a month.

-

Need Problem Solving - Bending Decorative layer on Quiver

DavidK posted a topic in How Do I Do That?

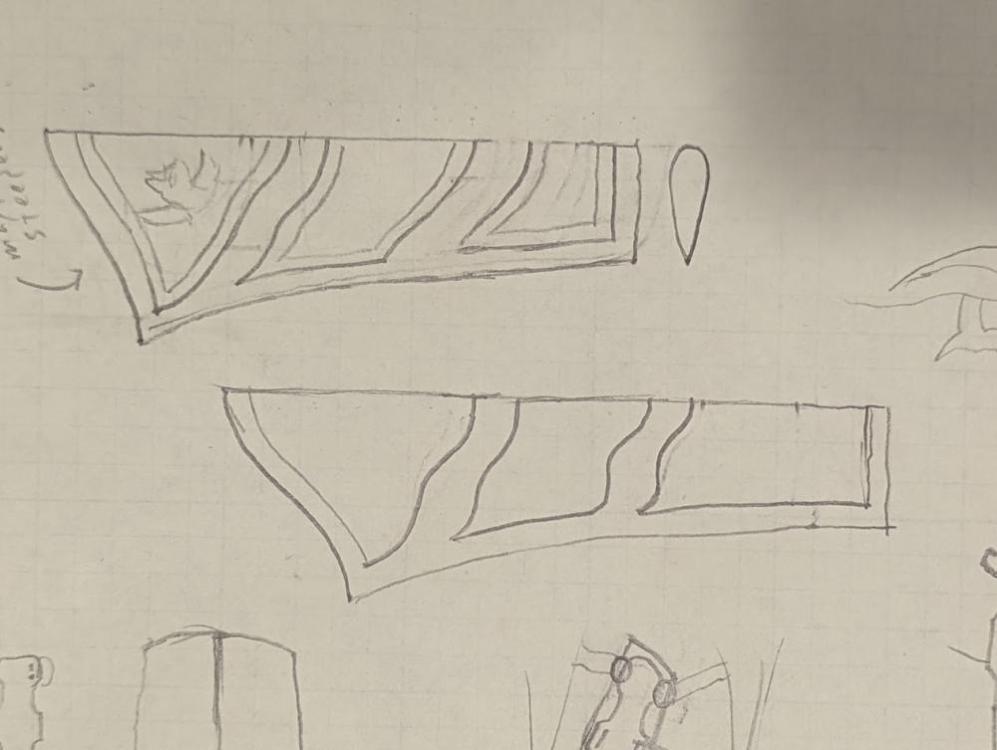

Hello, As an experiment im making an archery back quiver, and anticipating a problem. The pictures hopefully will make it more clear. I plan to attach these 3 5oz decorative panels to this 8oz quiver, the quiver will then fold in half and be stitched on the long side into a quiver shape. The anticipated problem will be that after stitching the panels on while the quiver is flat, the panels wont allow the quiver to then fold into the taco and stitch into final shape. Any suggestions here on how best to attach the panels, or if a product like shoe stretch leather could help (after attaching, maybe leaving a section unstitched to stick a dauber into the back of the panels and work it into the flesh side? Any suggestions appreciated, big, small, or project breaking Thanks! David -

I didn't put this in for sale because I don't own it or possess it at the moment. But there is an American straight needle available in Southwest Michigan. My understanding is that it either sews or is very near to sewing. It would end up being at most a few hundred dollars. If anyone's interested in discussing further send me a message. For more explanation it's part of a deal that I might do but have absolutely no room or need for an American straight needle.

-

THIS is s stitching machine! This was used in production for the backseat on tall bootlegs of heavy military and riding boots. Pay attention on the direction of the rolling foot! Not sure if on this photo you can guess the actual size of this machine, but a normal patcher would look tiny next to it...

-

Hi all, I recently picked up a box of miscellaneous leather tools and there were these four tools in it that I have never seen before and have no idea what they are used for. I was hoping you all could help me identify what their uses are. From left to right in the lineup: 1. Double-sided overstitch wheel (I know it's an overstitch wheel, but double-sided? How would I use that?) 2. Some sort of French Beveler or edge beveler, possibly for shoe making? 3. Some sort of creaser or little hammer thing? The previous owner sharpened the axe end because he wasn't sure what else to do with it. 4. An awl of some sort, I can't tell if the tip has been broken off or what the deal is. Very thick, blunt end, maybe was forked but broke off? Maybe for saddle making? Any help or ideas would be appreciated.

- 9 replies

-

- antique

- overstitch

-

(and 3 more)

Tagged with:

-

Hi all... My next holster in work...not done yet, but I couldn't wait to show off my stitchwork. I usually end up with so-so stitches at best, and stitching has been the bane of my existence for many years now, but I'm finally starting to catch on...and yes, the antiquing went weird somehow, but it's a different effect so I'm keeping it...Enjoy! -Mike

-

Saddle stitching. "Dot the i's and cross the t's". https://youtu.be/7e3HC9tuSXA

-

- stitching

- saddle stitching

-

(and 3 more)

Tagged with:

-

Hi all, I’ve got this awl (pun stubbornly intended). Picked up fairly cheap from something between a junk and antiques shop. I ground and polished the tarnish away on my sharpening stone if you’re wondering why it looks a bit strange. As you can see from the photos about 1/4 of the wood intended to hold the shaft (right term?) is gone. So the obvious question I have is what is the best way that doesn’t involve replacing the whole handle to secure the shaft and collar? Related to that, what’s with the angle of the shaft? I’ve tried it all four ways, and obviously due to the diamond shape it only fits in two, but it’s never centred. I don’t think this has to do with the bit that’s broken off, because to be centred there would have to be less material on the side that’s still there. In fact that’s probably why there’s that bit missing, because it would have been a fairly thin wedge. Is there some reason this awl is asymmetrically angled? And if so, which way is it meant to be held? I’ve got no idea what’s stamped on the shaft, it’s very worn. I’d be interested if anyone recognises it.

- 16 replies

-

- vintage tool

- awl

-

(and 3 more)

Tagged with:

-

Recently I bought a new diamond stitching awl off of Amazon because I wanted something that could do smaller holes than what my current awl provides. The awl arrived, and the blade promptly broke off at the shank after poking about 5 holes. I contacted the seller, and while they refunded the purchase price, they also told me "We immediately reported the situation to our professional craftsman, who advised our customers not to directly use the awl to punch holes. Since the tip of the awl is relatively sharp, it can only be used to assist in poking holes. After the hole is made, use an awl to reshape the hole." Does any of that make sense to anybody? Are they saying that I should be using something else to poke the hole and their awl is only meant to be used to shape an existing hole? That seems like a fairly cumbersome way to do stitching, but maybe that's what needed for smaller fine-detail stitching? Am I missing something? Meanwhile I went back to my old awl, which is still holding up fine. I may not have thousands of projects under my belt with that awl, but I have poked a few hundred holes with it. /dwight

-

I recently acquired a Bob Douglas awl haft and blade, and I must say - the awl haft is brilliant. I was dreading installing the blade in the haft on account of not having a vise to hold the blade between two pennies nor having experience with working with epoxy to stick the blade in. To install the blade into the Bob Douglas haft, you simply unscrew the ferrule nut, insert the blade, then tighten the nut. It self-centers, and it's brilliantly simple to swap between blades. Truly a work of functional art.

-

So I've tried to figure this out via youtube videos, but haven't found one yet that actually shows the precise moment I need to see. When the flap is sewn together at the ends of handle, how is the transition made to the other side of the stitching? I tried a couple of ways, neither was the proper method, as indicated by the nasty job I made of it. On one template, there were 8 stitching holes each side, with one at the point. That was interesting. The other one I saw had just the 8 or 9 holes on each side, without one at the point. The image below is the latter. Neither method is clear to me as to making the stitching transition from one side, past the point and to the other side.

-

-

Like new Barry King 48oz mallet! There are a few scuffs on the brass nut, otherwise very little use to the nylon head. Carefully-crafted mallet is a true work of art. Durable nylon head stands up to heavy-duty use. Contoured handle offers extra cushioning and is comfortable in the hand.

- 1 reply

-

- barry king

- barry king tools

-

(and 5 more)

Tagged with:

-

Like new KS Blade Punches (version 2)! Can be sold as a pair or single. This second version of KS Blade Punches are a bit slimmer and lighter for ease of use. The pricking irons are made of high-quality steel and have a nice weight to them. The heavier weight makes it easy to set the tool in the correct position, preventing it from moving on you. The width of the teeth are fairly thin (unlike many irons) and create a very clean, non-bulky opening for threading.

-

Like new KS Blade Punches! Can be sold as a pair or single. The pricking irons are made of high-quality steel and have a nice weight to them. The heavier weight makes it easy to set the tool in the correct position, preventing it from moving on you. The width of the teeth are fairly thin (unlike many irons) and create a very clean, non-bulky opening for threading.

- 1 reply

-

- leather punch

- leather punches

- (and 7 more)

-

I have some experience with veg tan but I’ve only ever connected pieces with rivets and buckles and so on. Very little stitching, no gluing. Now, I’m making a quiver. I’m buying new tools and doing a lot of research, as it’ll be my first times for carving, stitching, and gluing. I have some questions and concerns - I’m not working from an existing pattern. I’m thinking about closing the quiver’s long edge with a baseball stitch. The straps will be connected to that edge with overlays, and help reinforce the seam. Concerns: I’m designing the pattern with paper to start, and the construction paper warps into a teardrop shape without reinforcement at the seam. I worry I will have some weakness in the same area with 8 oz veg tan? Would it be more reasonable to use a butt stitch, even though I don’t prefer it aesthetically? Regardless of the stitch, should I, or would it be advisable to, contact cement (or otherwise glue) the butt edges of the leather together before stitching? Thanks for any tips, first time posting but I've been lurking for a long time.

-

Hey folks, I came here in the fall and asked some big questions, as this was an ambitious project. First time carving (the coaster in the album was my practice run) and first time stitching. I also hand-drafted the pattern (why make things easy?). I made tons of little mistakes (like why, or why, didn't I use an awl?). I also learned a lot, and I'm very happy with the overall results, and so was my niece! (it was a present for her). Thanks for all the help! The Making-of album: https://ibb.co/album/bbvb1X

-

Hi everybody. I make a lot of wallets and I recently got a new set of pricking irons. In the past, I've used the diamond stitching chisels from Weaver leather supply, and they were okay. I switched to the Sinabroks 3.38 mm pricking irons because I wanted something a little more refined. I've really enjoyed using them so far but I've come across a problem. If I'm stitching down a row of pockets like in a vertical long wallet, I can't seem to figure out a good placement for the holes. If I put one tooth on the bottom edge of one pocket and another tooth on the top edge of the next pocket, there isn't enough clearance because of the slant of the teeth, so there's only a tiny bit of leather there to hold onto the thread. If I were to stitch that up, it usually rips the edge of the leather. On the other hand, I can't put a hole between the two pockets because then there will be thread going between them and they won't meet up edge to edge flush and clean. Is 3.38 mm just too small? I'm pretty certain I've seen people stitch up wallets with that size before, even finer sizes. Any advice would be appreciated. Thank you.

- 2 replies

-

- wallets

- pricking irons

-

(and 2 more)

Tagged with:

-

I am looking at buying myself an industrial cylinder bed sewing machine. I mainly do small to mid sized projects like belts, wallets, bags, etc. I have been looking into buying a Cobra class 26 until recently I found a 10 year old Adler K269 single needle walking foot for sale for around $1700 for stand and everything. I am wondering if this is a good deal, and if it a high quality machine with similar capabilities as the Cobra class 26. Any information on this would be a huge help.

- 1 reply

-

- sewing machine

- sewing

-

(and 2 more)

Tagged with:

-

Like new Amy Roke Pricking Irons! Can be sold as a pair or single. The Amy Roke European style pricking irons are made of high-quality steel and have a nice weight to them. The heavier weight makes it easy to set the tool in the correct position, preventing it from moving on you. The width of the teeth are fairly thin (unlike many irons) and create a very clean, non-bulky opening for threading.

-

- stitching

- leather punches

- (and 8 more)

-

Like new Amy Roke Pricking Irons! Can be sold as a pair or single. The Amy Roke European style pricking irons are made of high-quality steel and have a nice weight to them. The heavier weight makes it easy to set the tool in the correct position, preventing it from moving on you. The width of the teeth are fairly thin (unlike many irons) and create a very clean, non-bulky opening for threading.

-

- hand stitching

- stitching

- (and 7 more)

-

This might seem like a silly question, but does anyone have advice about being able to get a good grip on needles when hand stitching? I try and use the old Al Stohlman method of a needle and an awl in one hand and a needle in the other, but I find myself constantly setting down my awl to grab pliers to pull my needle through. Any advice would be greatly appreciated.

-

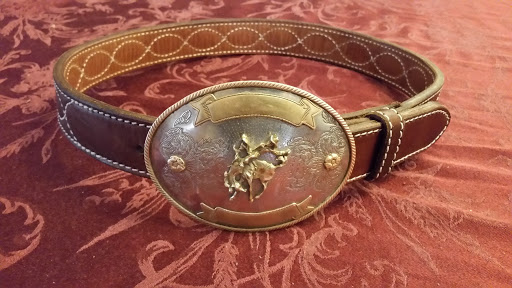

Hello, guys! So as a leatherworker, I thought I should be wearing a belt that I made... so I made one my style... thick. I used two pieces of 9 oz leather at 1.5 inches wide... do the math and you get an 18 oz thick belt. I glued the flesh sides together and then stitched it up so I have the smooth on both sides. It's like lining it with itself. It should last the rest of my life as well as my future kids and grandkids and so forth. It will also make a very good spanking strap. (Note: I did not make my dad one.) Comments/critique welcome. Oh, and before you ask, no, I didn't win the buckle. Thanks for looking! -Ryan

- 14 replies

-

Hello Everyone! I have a couple of Vergez Blanchard tools for sale that I got as a gift but never got around to using them. First there is a stitching roulette or pricking wheel with guide and includes #7, 8, 9, 10, 12 wheels, and a saddler's knife which is used to trim leather edges or cut veg tan leather used in the saddlery trade but not limited to it. Stitching Roulette - USD 240 Saddler's Knife - USD 60

- 1 reply

-

- blanchard

- pricking wheel

- (and 4 more)

.jpeg.63cb0ab3c5c213e7640e5316066b2940.jpeg)