-

Posts

421 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Hildebrand

-

No expert but best guess is the leather is tipping into the hole in the sewing machine as the needle pushes down, and it is doing this in varying amounts. I have to be very careful when I sew holsters that are double thickness plus a welt down the seam or the back doesn't match up with the front and it will vary like yours does. Todd

-

Nice job @chuck123wapati that looks great. Perfect engineering to get an unavailable tool. Todd

- 20 replies

-

- hard to find hardware

- border stamp

-

(and 2 more)

Tagged with:

-

@leather20 I have started using one of the circular light/magnifier combos when I tool. It is on a movable arm andI can position it so I am looking through it or it is above just lighting the project. It makes it much easier to get the tool exactly where you want it. Also makes the swivel knife cuts easier. Todd

-

@Loquai as someone who had a Tippmann Boss, pretty much like the Outlaw, I don't recommend it. It did a good job sewing but I spent a ton of time fiddling with tensions and was constantly afraid to even change out the thread color for fear of something going out of tune. The second part of that is you only have one hand to hold what you are sewing with the Outlaw, while you crank the handle with the other hand. it was amazing to me how much easier it is to sew certain things since I can use both hands to guide them. Todd

-

Chest rig for a Glock 26

Hildebrand replied to Hags's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looks great I am getting ready to make myself one for a 1911 10mm. Todd -

Depends on the end use of the belt. Very few single layer belts will hold up to carrying a holster daily without stretching. Todd

-

Looks really good Frodo. Luckily we don't have that big of a snake problem around here, its enough to just be cautious and watch where you walk. Todd

-

@Paultalks in reading this thread maybe back off just a hair. You have been beating on these people pretty hard. Given they blocked you on social media I am not surprised you haven't gotten responses to your emails and letter. Maybe take a step back, order online for a bit and see if things slowly return to normal. Like it or hate it businesses have to operate under the state, county and city guidelines until this pandemic is over. Todd

-

Lined Loop Holster for 5" 1911

Hildebrand replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Another impressive piece Josh. Todd -

To prevent any chance the metal from the back of a snap contacting the gun in any way. In most cases it is the back of a snap on a thumb break. You can't really predict where the snap goes on the piece which crosses over the gun, this leaves the back of the snap exposed once you set it in place. I place as many snap backs between layers of leather as I can but occasionally you have one end up exposed. Todd

-

Belt, Holster, Mag pouch set

Hildebrand replied to Hildebrand's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank you Josh I appreciate the kind words. Todd -

I use the little plastic screw covers the Home Depot sells. I just glue them on, I think they come in different colors. Store SKU #583539 Todd

-

Belt, Holster, Mag pouch set

Hildebrand replied to Hildebrand's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank you all. Chuck, that is double layer 16 or 17oz it is right at or just over 1/4" I don't think I measured it once it was stitched. Todd -

1911 mag holder/pouch

Hildebrand replied to dikman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I would go to JLS Leather on Etsy. He sells a pattern pack for mag pouches. It has single and double pouches for 1911. I have several of his patterns and they are all spot on stitching line wise. Todd -

Holster Liner Material

Hildebrand replied to DuqQuaid's topic in Gun Holsters, Rifle Slings and Knife Sheathes

In answer to your question about the inside of the leather being like suede, yes it is. That is what lead to the lined holsters. Also with the lined holster you get a stiffer holster which holds its shape really well. I have a couple that there is actually a click when you insert the gun. Todd -

Holster Liner Material

Hildebrand replied to DuqQuaid's topic in Gun Holsters, Rifle Slings and Knife Sheathes

@Frodo I am going to respectfully disagree. The suede type leather traps any grit and gunk you bring in when you holster your gun. Also I think the majority of suede leather is chrome tanned. I will stick with veg tanned liners, a little blue wear is better than a scratch from a piece of trapped grit or rust from the chrome tan chemicals. Todd -

Holster Liner Material

Hildebrand replied to DuqQuaid's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yes Adams leather he is with hank strange. I think you loose a little with the textured leather but it will work fine for practice. Todd -

Holster Liner Material

Hildebrand replied to DuqQuaid's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Definitely stay with the veg tan for a liner. You can prebend but I routinely use two layers of 4-5 sometimes 5-6oz leather and have never had a problem with it wrinkling when bent. I always wet the centerline I am bending around inside and out pretty well before bending. I also have a shadow 2 and am working on a holster pattern. I highly recommend Sam Adams YT video where he shows how to get the stitch lines and then draw the holster. Adams Leather Works has a couple similar videos where he details how he gets the stitch lines. Also not sure how much detail you are shooting for but if you are looking to "bone" the holster for the gun detail to show through a lined holster makes that much more difficult. Good Luck, Todd -

With leather everything is a give and take. Best advice I have is get some chrome tanned and some veg tanned leather and make your products then test both and see what holds up better for your conditions. Todd

-

@MCarlosED usually items like belts and ammunition carriers are made from Veg tanned leather. Cartridge loops made of chrome tanned leather would be to soft and wouldn't hold the shells, same for belts. I have no experience with carnauga wax, I just bought a bottle but haven't used it, but I have not had any failures using a top coat of resolene cut 50:50 with water. Mop and Glo floor polish cut 50:50 with water also works but there is usually a slight flowery scent. Todd

-

Never found a good source, but frankly it would be cheaper than $7 plus shipping to just buy the ready made belt tape measure holders and take the clip off thats what I have done for the ones I need. Todd

-

16 Ounce Strap Supplier, 1907 Leather Sling Build

Hildebrand replied to AlamoJoe2002's topic in Suppliers

For a use like a sling if you are going to go with 2 layers you really do need to sew it. If you don't have a machine you may be able to take it to a saddle or boot repair shop and pay them to sew it. A sling from a competitive shooters is going to be subject to a lot of different stresses while he uses it as well as adjusts it for the different positions. Todd -

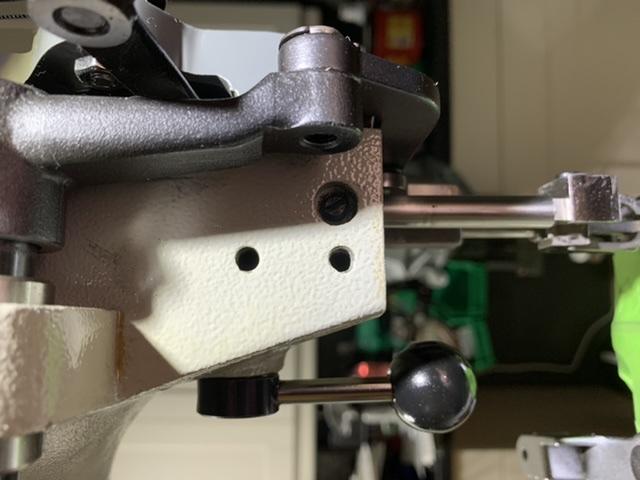

Drop down edge guide for CB 4500

Hildebrand replied to Hildebrand's topic in Leather Sewing Machines

It appears mine has 2 threaded holes on the back so I am set. Thank you everyone for the help. ToddSorry the picture is sideways. Not sure how to rotate it. -

Drop down edge guide for CB 4500

Hildebrand replied to Hildebrand's topic in Leather Sewing Machines

Uwe, Thank you for the information. I will get a picture of the back of the machine tonight. Todd