chrisash

Members-

Posts

2,133 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by chrisash

-

I used a carpet spray on tin to spray on, I taped over the borders prior to spraying etc so the glue only went where needed, then removed the tape and rolled on the fabric, there was no seep through and time enough to roll the fabris flat and remove any creases This was POly/Cotton to Horoween

-

There are approximately 100,000 ways to case leather each with there own interpretation of perfection and non in agreement with any other I would suggest you do a search on this forum for casing and take your own pick, me i just give it about three or four swipes with a wet sponge and when it looks dry start working but i am in noways a expert just a learner, so I guess look at the sugesters work and pick the best method they use

-

OK I give in, what is a hackysack, sorry but not obvious from the photo's

-

Watched a video of a guy using a arbor press with the stamp shaft held in the arbor so he only had to move the leather and use the arbor handle to press the stamp in Results indicate a steady inprint and easier to position the leather than the stamp I guess there is no correct way just what works best for you and all need some practice Given it some trials myself in a little way and looks OK and using 3D printer it seems no reason you are limited to single stamps, maybe put 3 or 4 baskets in one stamp if the press is powerful enough

-

MY63 One thing you can get which is cheap and has plenty of space and no planning laws is a ex mobile home as long as you keep the wheels on they avoid any laws, they can look ok and often very cheap about 30ft x 12 ft with easy interior walls to knock down, other options are portacabins or shipping containers Don't forget security is essential Chris

-

Is it possible to take it to a service engineer and get a quote for sorting it out prior to buying it, and then you have room to negotiate on the price. you may have to leave it a couple of days for the check $500 plus say a couple of hundred in repairs may make it a expensive buy

-

consew stitching, singer takeup cam, vibrations

chrisash replied to ensitmike's topic in Leather Sewing Machines

I think I would loosen off the bobbin a small touch, to me it looks a bit to tight and cutting in, a fine balance between looks and thread tension -

I am not impresses by looks but by fit for purpose, I cannot see this square tip being as low in initial resistance as as semi pointed version, and the more layers it goes through the more resistance which to me is opposite to what you need Titanium has strength but no reason to use it in this usage so more a gimmick, and whilst i can understand people liking a nice looking item, that's just a matter of personal choice I have seem many Shotguns with £2000 original gun and £4000 worth of stock and front end on them, and £6000 guns with quite plain wood, I know what I would buy and let my shooting make the statement

-

Love the bags what is the Al Paker white one made of?

-

Actually in the first post he mentioned upholstery leather to match the seat and have a veg tan inner piece, so no reason it would not last

-

I believe that the use of lead shot is to spread the weight around the shape of the head rather than have sharp parts or solids in one place which might kill rather than stun or knockout

-

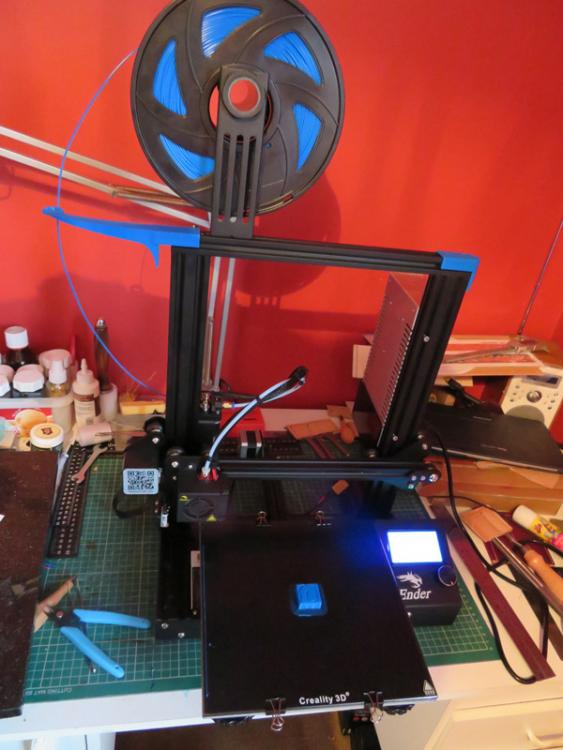

This is my ender 3 I can only recommend it very highly as great results and only £150 Still learning Fusion 360 hense the test piece using the pipe command Happy Christmas to all

-

Why not wrap the chrome right around the veg tan and match its ends in the center of the inside and then sew two lines about 3mm from the center to hold it in place, that way there is no edges, just a seam in the center back

-

Merry Leathercrafting Christmas

chrisash replied to Handstitched's topic in Leatherwork Conversation

Have a great Christmas and new year Chris -

List of Youtube Leathercraft channels

chrisash replied to Caesar's topic in Leatherwork Conversation

But is not your JLS leather rather than your name on the forum and the advert for the sewing machines not also adverts? -

Dont forget the selling costs, it's easy to add up the costs of leather dye and time etc, but, and a big but, selling your products takes a massive amount of time, and that sort of time, is very hard to break down, be it running e=commerce, or driving two hours to visit the bank or accountant, all take actual leatherworking time out of what's available to make things With e-commerce Search engine optimisation is a constant hurdle taking up great amounts of time just on the hope that what you are doing is going to improve your clicks per day/ month It's also very easy to get depressed when you consider all the hours you could have spent on the bench rather than admin Have a great Christmas and very wealthy new year

-

List of Youtube Leathercraft channels

chrisash replied to Caesar's topic in Leatherwork Conversation

Plus Harry Rogers https://www.youtube.com/results?search_query=harry+rogers -

Make a thick card template and fit together with sellotape or pins and adjust to fit and when happy take apart and use a template for cutting the leather, dont forget to make allowances for seams etc

-

WE have another one "A fool is easy parted with there money" Trouble with expensive tools is you want to believe they are the best , which makes it very hard to judge if they are the best or just a talked up value

-

You could use the tactic some of my old customers used, something like a letter / email to Singer stating my machine broke after only 100 years so i demand a replacement, although in my case it was workwear that had not lasted being used for three years or something like the red uniform is to red even though they had photo's before they ordered it LOL chris

-

Sticking with chisels instead of pricking irons...

chrisash replied to scrapyarddog's topic in Leatherwork Conversation

In my short time in leather work, one thing I have learnt is that there is no right or wrong way to work, you just use what is best for you, experts can guide you and assist with problems you have along the way, but it's up to you to follow your own idea's or there's -

Need some serious helps on buying a leather sewing machine

chrisash replied to shantiandd's topic in Leather Sewing Machines

Do you really need a Cylinder machine is the first question, whilst they can be versatile for some uses, they have no real advantage if you are only sewing flat items Wiz has a great post here on what to look for Adler are great machines but so are the lower cost ones, just look at the 100 year old machines owned by experts on this forum, the job is quite basic for leatherwork a simple lockstitch, so it may be worth looking around to see what else fits your requirements and that may include two machines one for thin and one for thick as there is no machine that handles both sizes well, also consider support -

You could wet mold it to toughen it up to a strong flat surface

-

Does anyone make traditional clicking patterns?

chrisash replied to bermudahwin's topic in Suppliers

Hi Harry http://www.presageservices.co.uk/ -

longer stitching punch?

chrisash replied to archeryrob's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Punch through the top two layers, then use awl on the last layer putting it through the top two layers for accuracy, whilst going through the bottom layer with the awl